Introduction:

Like many locations in the Boston metro area, East Boston is exploding with redevelopment activity of residential and mixed-use properties. These urban projects face challenges of constrained sites, access issues and impacts of vibrations on nearby properties. In addition, identifying the best foundation value to address the geotechnical and structural requirements is a challenge in itself for project teams because of the presence of fills, organics and soft clay.

Construction at 47 Webster Street consisted of demolition of an existing 2-story structure with a partial basement followed by construction of a new 4-story, 11,560 square foot mixed-use building. Adjacent buildings were located within 20 feet.

Geotechnical Conditions:

The geotechnical exploration at the site encountered sand fill extending up to 12 feet below grade, followed by 5 feet of very soft to soft organic material and very soft to soft silt and clay extending to at least 35 feet below grade. Stiff silt and clay were then encountered to the maximum explored depth of 72 feet. Groundwater was encountered at a depth of about 5 feet below grade.

Project Challenges:

Foundation support in fills and soft soils at a congested, vibration-sensitive urban area.

Advantages

- Rapid installation

- Low vibrations in residential area

- Ease of access on congested urban site

- High capacity

- Verifiable performance with load testing

Design and Construction Solution:

The presence of undocumented fill, organics and soft clay drove recommendations for a series of pile supported grade beam foundations. Pile options included steel H-piles, helical piles, timber piles and Ductile Iron Piles. The design documents were prepared based on steel H-piles with a 40 ton working capacity. After evaluating the different foundation options, J.L. Dunn selected the Ductile Iron Pile option at a 1:1 replacement of the steel H-piles. Speed of installation, cost and low vibration levels were all important considerations to the overall value afforded by the Ductile Iron Pile solution.

Helical Drilling, Inc. designed the Ductile Iron Pile system using Series 118/7.5 (118 mm diameter with 7.5 mm wall thickness) piles to provide an allowable capacity of 40 tons. The piles were designed to generate capacity by terminating in very dense glacial till or rock with anticipated depths of 90 to 100 feet based on deep explorations from nearby sites.

Installation of 43 production Ductile Iron Piles was accomplished in 3 days with one additional day to perform a full-scale compression load test. Pile lengths ranged from around 65 to 85 feet with an average near 75 feet. Production ranged from 800 to 1,200 linear feet per day.

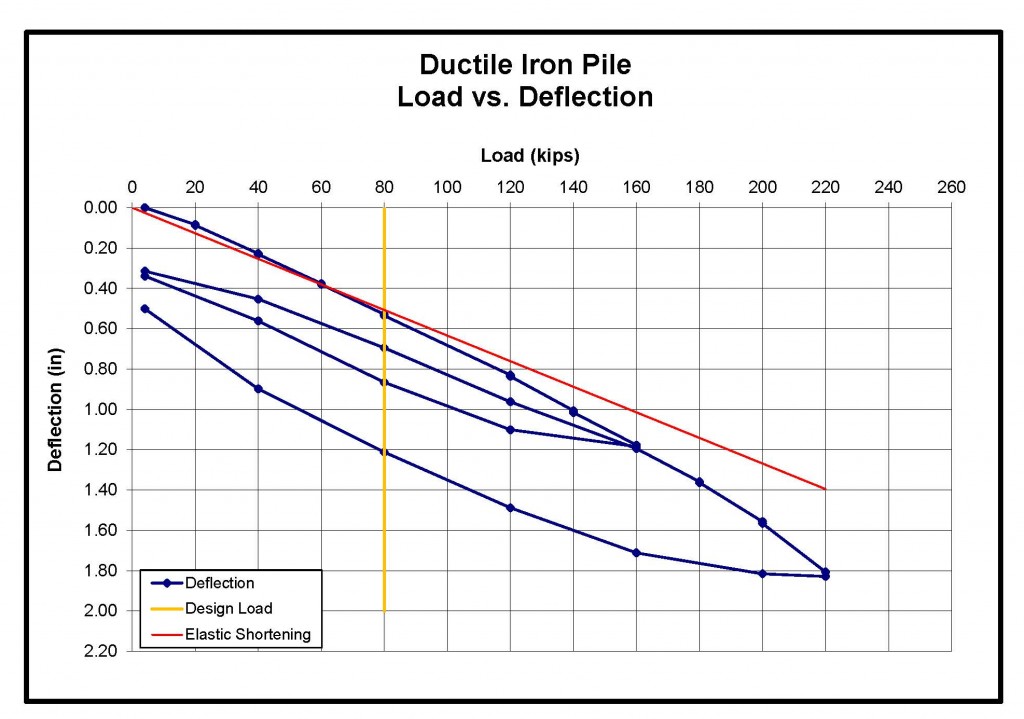

A full-scale compression load test was performed to confirm the design capacity of 40 tons. Deflection was limited to 0.54 inches at the design load of 80 kips. The test was performed to 160 kips (200%) where deflection of 1.19 inches was recorded. The net deflection after rebounding showed only 0.32 inches of movement indicating the extent of elastic shortening during loading. The pile was then loaded to 220 kips (275%) where a continued linear response was noted with 1.82 inches of total movement followed by only 0.5 inches of net deflection on unloading. The results confirmed the working capacity of 40 tons with potential increases in working capacity up to 55 tons

with acceptable performance.

Project Team Members

DIP Design/Build Partner: Helical Drilling

Geotechnical Engineer: PSI, Inc

General Contractor: J.L. Dunn, Inc.

Construction Manager: First Cliff Construction Consulting, LLC

Structural Engineer: Bolton & DiMartino, Inc.