Introduction:

Reconstruction of the Vermont Waterbury State Offices Complex included construction of a heavily-loaded mat foundation used for a woodchip storage pit within the wood-fired biomass central plant. Project specifications required 8-inch drilled micropiles for compression and tension resistance. Pile installation would be challenged by the working pad level located in the depressed storage pit excavation.

Geotechnical Conditions:

Soil conditions in the area of the Central Plant Wood Chip Storage Pit consisted of approximately 6 feet of silty sand FILL in some locations followed by up to 10 feet of loose SILTY SAND becoming medium dense to dense SAND and GRAVEL with cobbles and boulders before rock was encountered at depths of 50 to 55 feet. Groundwater was encountered about 15 feet below grade.

Project Challenges:

Provide a system for supporting the heavily-loaded wood chip mat foundation while working within a pit excavation.

Advantages

- Cost savings over traditional deep foundations

- Flexibility of installation from various grades and locations

- High capacity for reduction of scope

- Rapid installation

Design and Construction Solution:

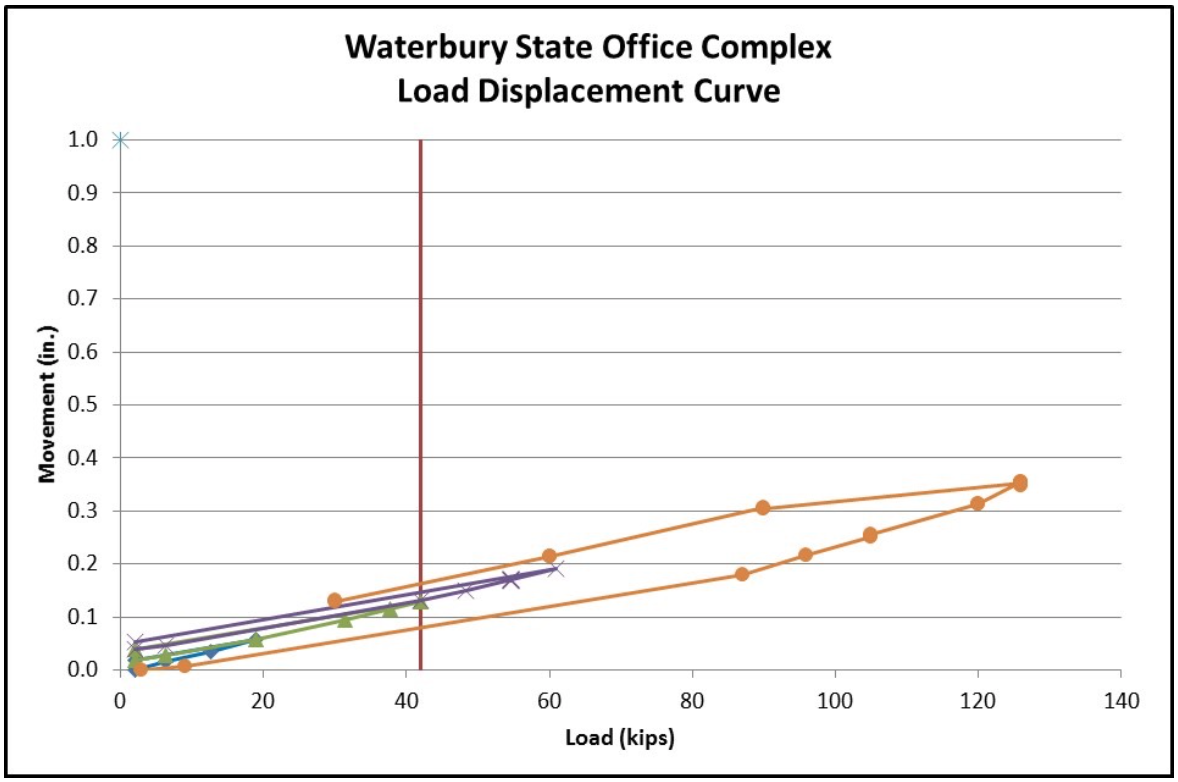

As an alternative to the specified drilled 8-inch micropiles providing 40 kips of compression and tension resistance, Helical Drilling proposed a more cost-effective approach using 4.65 inch diameter (Type 118) Ductile Iron Piles (DIPs) – grouted to provide frictional resistance for both tensile and compressive loads. The value engineering proposal was accepted by the project team. The DIPs were advanced 32 feet below the pit slab sub-grade through the dense sands using an 8 5/8 inch conical grout point, rammed by a Tramac V1800 Hammer mounted on a Volvo 240 excavator. Penetration rates were on the order of 25 seconds per meter (8 seconds per foot) within the upper loose sand and slowed substantially in the dense underlying sand. The design bond strength and embedment length were verified with a tension load test. After the load test was completed, the pile was re-tested to a load of 120 kips (300% of the design load) – the structural capacity of the reinforcing bar. This additional testing confirmed that the use of grouted friction DIPs develops much higher bond stresses due to the displacement nature of the pile construction process.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: GeoDesign, Inc.

Construction Manager: PC Construction

Structural Engineer: Engineering Ventures, Inc.

Architect: Freeman French Freeman, Inc.