Ductile Iron Piles Provide Low Overhead Foundation Solution

Project Description:

The project involved construction of a new mezzanine expansion within an existing shipping distribution facility. Overhead clearances were limited to about 20 feet. The addition of 18 new column locations required saw-cutting of existing slabs prior to foundation construction. Column loads required support for compression loads of up to 180 kips along with both tension and lateral loads.

Geotechnical Conditions:

Soil conditions consisted of medium dense to dense granular fill to depths of 5 to 7 feet followed by medium dense sand and gravel. The sand and gravel layer extended to 22 feet followed by medium dense sand and silt to the maximum explored depth of 27 feet at one end of the mezzanine area. The sand and gravel extended to depths of at least 26 feet at the opposite end of the area. Groundwater was measured at 5 to 7 feet below grade.

Project Challenges:

Provide cost-effective, reliable foundation support for new interior columns in low-overhead conditions while working around active distribution activities.

Advantages

- Reduced installation and performance uncertainty compared with helical piles

- Reliable capacity with grouted friction bond zone

- Low overhead clearance for interior construction

- Low vibrations

Design and Construction Solution:

Project documents specified a contractor-designed helical pile system capable of resisting 30 tons (compression), 10 tons (tension) and 2.5 tons of lateral loading demands. Looking to reduce the potential risk of uncertainty with helical pile capacities and installation challenges, the General Contractor selected a friction Ductile Iron Pile approach proposed by Helical Drilling, Inc.

The Ductile Iron Pile (DIP) solution delivered a 1:1 replacement to address the helical pile loading requirements. The system incorporated a Series 98/6.0 pile (98 mm outer diameter with 6.0 mm wall thickness) installed with an oversized 180 mm conical cap to allow grouting of the pile interior and the annular space along the pile exterior during driving. The exterior grout layer produces significant and reliable frictional capacity from the combination of densification during driving and the grout-to-ground bonding. A 1-inch diameter Grade 75 threadbar was installed full-length in the center of the grouted piles to resist the tension loads.

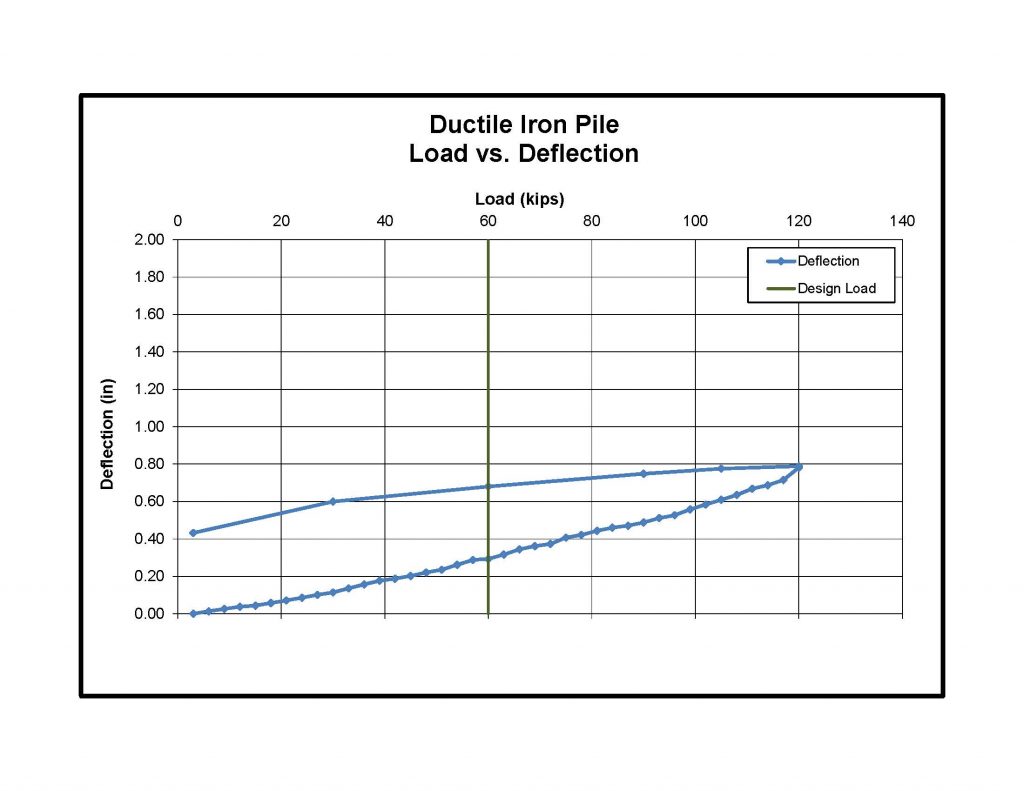

Full-scale tension load testing was performed on a non-production pile to confirm the development of the frictional capacity. The 24-ft long test pile with a nominal 7-inch diameter grout zone exhibited about 0.3 inches of movement at 30 tons (100%) and about ¾-inch of movement at 60 tons (200%). Results of the tension load test confirmed the acceptance of the Ductile Iron Pile solution to more than meet the specified design capacities.

A total of 79 production piles with average lengths of 24 feet were installed on the project. Due to low overhead conditions, piles were installed from within the excavated pile cap locations using cut pile sections and couplers to splice the piles. All load testing and production installations were completed in only 9 working days. The use of Ductile Iron Piles provided a reliable, economical foundation option that reduced the risk for unanticipated capacity and installation issues and afforded schedule savings.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: GZA GeoEnvironmental, Inc.

General Contractor: CVMNEXT Construction

Structural Engineer: CVM Engineers