Ductile Iron Piles provided low vibration, cost-effective foundation support immediately adjacent to an existing vibration-sensitive retaining wall.

Project Description:

Following demolition of the existing structures, a new 161,000 square foot movie studio with up to six separate high-story sound stages was planned in the Bushwick neighborhood of Brooklyn. The rear of the new building abutted an existing, vibration-sensitive retaining wall at the property line. Foundation support for the building along with a new abutting retaining wall was required. Retaining wall loads along the back wall were up to 14 klf.

Geotechnical Details:

Soil conditions consisted of very loose to dense undocumented fills (sand, silt and debris) to depths of about 10 feet followed by up to 5 feet of soft to stiff organic silty clay underlain by medium dense sand (NYCBC Class 3b). SPT N-values in the sand layer were typically in the range of 20 to 40 bpf. Groundwater was encountered at depths of about 13 feet below grade.

Project Challenges:

Provide low vibration, cost-effective foundation support immediately adjacent to an existing vibration-sensitive retaining wall.

Advantages

- Low vibrations.

- Improved access adjacent to existing structures.

- Rapid installation compared with micropiles.

- Substantial cost savings compared with other pile systems.

- Controlled grouting for cleaner installation than micropiles.

Design and Construction Solution

Ground improvement was planned to reinforce the fill and organic soils to provide foundation support across the majority of the site. However, an alternative foundation solution to provide low vibrations and better horizontal / vertical accessibility was needed for support of the new retaining wall foundation along the back property line abutting the existing vibration-sensitive wall. The project team considered options including micropiles, drilled displacement piles and helical piles. Working closely with the geotechnical engineers, GeoStructures, Inc. proposed the use of low-vibration, grouted Ductile Iron Piles to provide both compression and tension resistance while allowing work within 1.5 feet of the existing wall.

Ground improvement was planned to reinforce the fill and organic soils to provide foundation support across the majority of the site. However, an alternative foundation solution to provide low vibrations and better horizontal / vertical accessibility was needed for support of the new retaining wall foundation along the back property line abutting the existing vibration-sensitive wall. The project team considered options including micropiles, drilled displacement piles and helical piles. Working closely with the geotechnical engineers, GeoStructures, Inc. proposed the use of low-vibration, grouted Ductile Iron Piles to provide both compression and tension resistance while allowing work within 1.5 feet of the existing wall.

GeoStructures, Inc. prepared a solution consisting of a Series 118/7.5 Ductile Iron Pile with a 220 mm conical grouting shoe to build an 8.5-inch diameter grouted displacement pile. Piles were designed to resist up to 75 kips in compression. With the addition of a #8 Grade 75 ksi thread bar wet set in the center of the pile, select piles also resisted up to 37 kips of tension demand due to overturning of the new wall. Pile lengths of 32 feet (2 of the 5 meter modular pile sections) were planned for installations resulting in a bond length of 17 feet below the fill and organics.

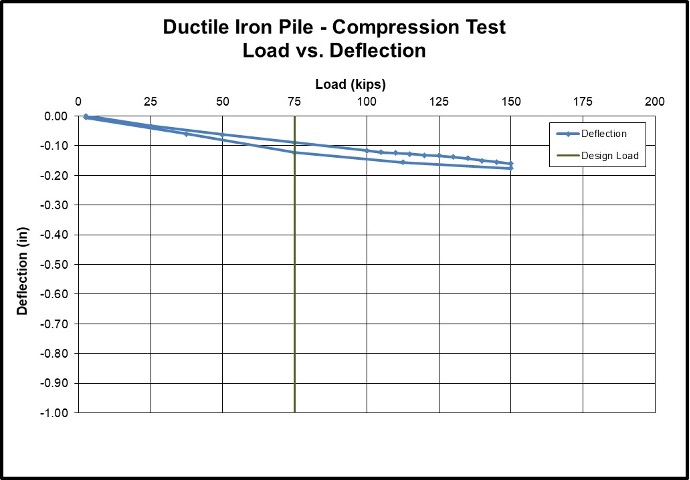

After mobilizing to the site, design/build partner Ground Improvement Services, Inc. installed the load test piles to verify the pile performance in both compression and tension. The compression test (ASTM D-1143) was performed to a maximum load of 150 kips. A maximum deflection of 0.18 inches was recorded at 150 kips. The tension test (ASTM D-3689) resulted in a deflection of only 0.05 inches at a maximum test load of 48 kips. Results of the load tests confirmed the design was adequate.

Ground Improvement Services, Inc. proceeded with installation of 195 Ductile Iron Piles along the back property line for retaining wall support. Over 6,200 LF of Ductile Iron Piles were installed with one crew in 11 days at the site. The low vibration installation of the Ductile Iron Piles minimized any impacts on the existing wall.

Project Team Members

DIP Designer: GeoStructures, Inc.

DIP Installer: Ground Improvement Services, Inc.

Architect: BLD Architecture

Geotechnical Engineer: Mueser Rutledge Consulting Engineers

Structural Engineer: Wayman C. Wing Consulting Engineers

General Contractor: Aurora Contractors, Inc.