A Low Vibration Solution with Driven Ductile Iron Piles

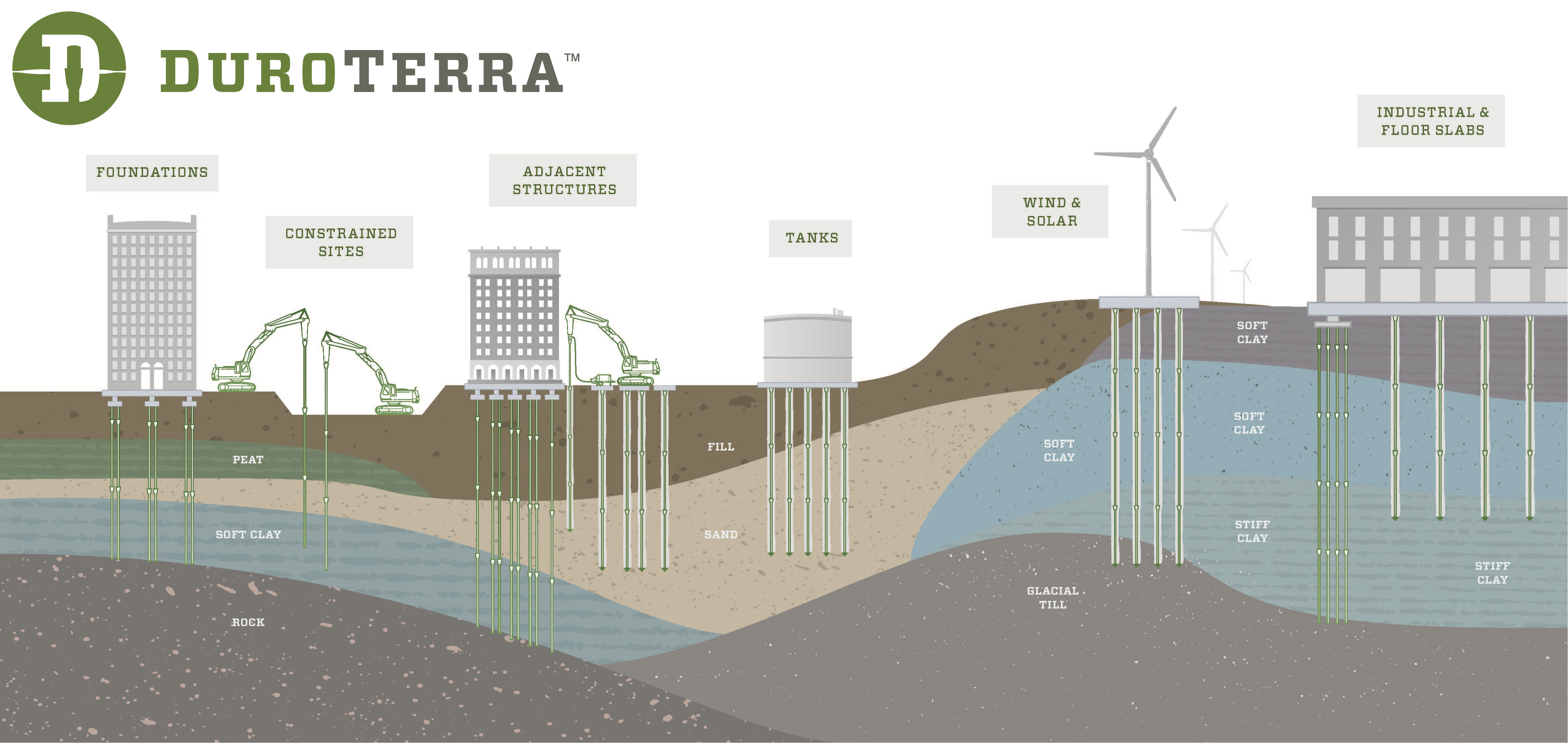

Traditional driven piles are often associated with high vibration installations. As Jerry Lee Lewis might have sung “there’s a whole lotta shakin’ going on.” But that’s not the case with TRM’s Ductile Iron Piles – a low vibration driven pile system. Instead, it’s more like the Beach Boys singing “Good…good….good…Good Vibrations.” That’s right – Ductile Iron Piles are a bit of a paradox in the driven pile world. The system provides many of the benefits of a driven pile including speed and cost-savings AND is a low vibration option that is often selected as an alternative to micropiles or helical piles on sites where vibrations are a concern.

How is that possible? Ductile Iron Piles are installed with an excavator-mounted hydraulic breaker hammer (i.e. demolition hammer) that delivers direct percussion energy (not vibratory) to the pile head. While the energy per blow is much lower than a traditional diesel hammer, the hammer strikes at a much higher frequency to deliver the driving energy. The typical impact frequency ranges from 300 to 600 blows per minute – that’s 5 to 10 blows per second! But unlike a vibratory hammer used for some pile installations, this energy remains direct impact energy. The combination of the lower energy/blow and the higher frequency impact results in a system that rapidly drives the pile with minimal vibrations.

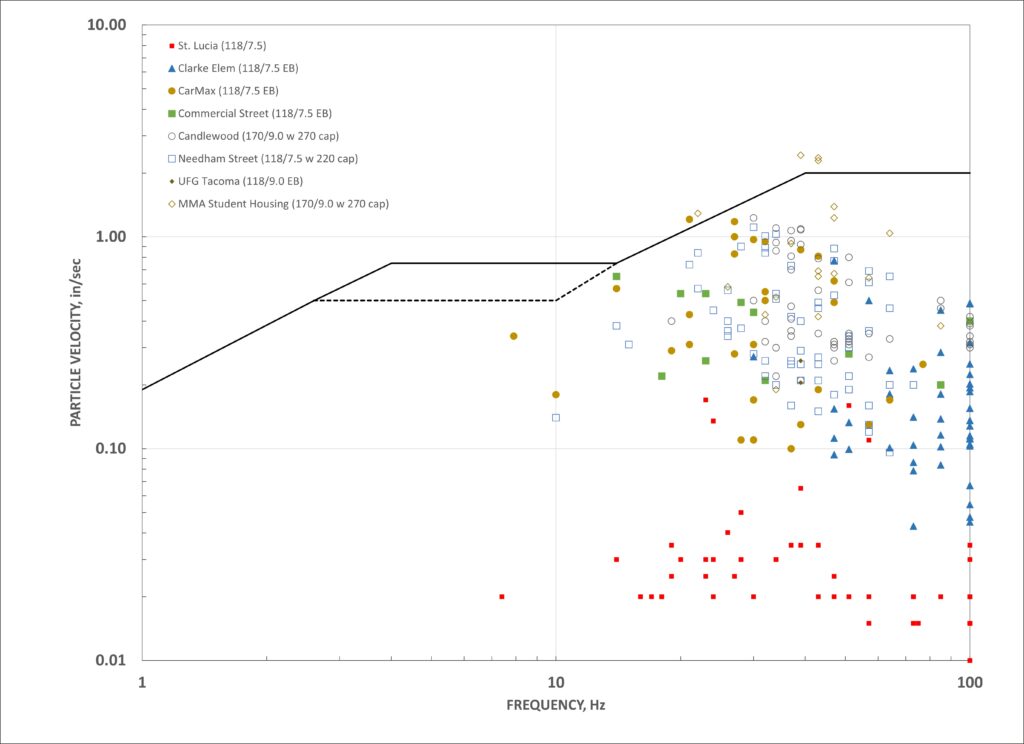

Substantial vibration data has been collected at various project sites to verify acceptable levels and also provides project teams with information to assess the feasibility of using a Ductile Iron Pile solution. These data are summarized in the Tech Brief on Ductile Iron Pile Vibration and Sound. As shown, the measured peak particle velocities (PPV) are typically between 0.25 ips and 1.0 ips at distances of only a few feet from installation.

The low vibration levels combined with the ability to install Ductile Iron Piles in limited overhead areas or on constrained sites adjacent to existing buildings have made DIPs a preferred option for many projects. Check out a couple of the projects where minimizing vibrations contributed to the successful incorporation of Ductile Iron Piles. Looking for a cost-effective, low vibration option on your project, reach out for a feasibility assessment by one of our engineers.

PROJECT EXPERIENCE – PHYSICIANS’ CLINIC OF IOWA PARKING GARAGE

Vibration concerns raised during ground improvement installation at the site of a new 5-story parking garage drove the need for a low vibration foundation support solution abutting the neighboring existing building. Foundation loads were up to 900 kips in this area. The project team opted for a low vibration driven Ductile Iron Pile solution to provide a 65 ton pile installed to rock at depths of 30 to 40 feet. Maximum vibration levels measured only 0.26 in/sec at a distance of less than 10 feet from pile installation – well within the 0.4 in/sec threshold. A full-scale load test was used to verify performance and showed less than ¼-inch deflection at the design load of 65 tons. A total of 44 piles were installed for support of the pile caps.

PROJECT EXPERIENCE – TULSA ZOO ELEPHANT PRESERVE

Construction of a new elephant experience and preserve included a new state-of-the-art barn and 10-acre fenced area. The 36,000 sqft barn had loads ranging from 60 to 175 kips. With ground conditions consisting of very soft to firm clay to depths of 34 ft underlain by loose silty sand to 44 feet followed by shale bedrock, deep foundations were needed to support the new structures. Besides providing a cost-effective solution, the deep foundation system needed to minimize vibrations to avoid disruption of the zoo animals. Low vibration Ductile Iron Piles were specified for the project over drilled shafts which would require casing for installations in the high groundwater and very soft clay conditions. A total of 82 Series 170/9.0 piles were installed to depths ranging from 50 to 55 feet at an average rate of over 900 LF per day. The fast production rate combined with the low vibrations had a low impact on the surrounding areas.