Ductile Iron Piles provided support for compression, tension and lateral loads with demonstrated performance at the site with undocumented fill and shallow groundwater.

Project Description:

Construction consisted of a new 42,000 square foot, 2-story headquarters building on the Rhode Island Air National Guard (RIANG) Base. The new building includes medical and dining facilities as well as administrative areas. Column loads for the steel-framed structure were up to 400 kips. Foundations were also subjected to tension and lateral loads.

Geotechnical Conditions:

The subsurface conditions at the site consisted of loose to very dense sand fill ranging from 4 to 10 feet below grade followed by medium dense to very dense glacial deposits of sand, silt and gravel to the maximum explored depths of up to 61 feet. Groundwater was encountered 7 to 9 feet below grade in the borings.

Project Challenges:

The project required a deep foundation solution to provide support for compression, tension and lateral loads with demonstrated performance at the site with undocumented fill and shallow groundwater.

Advantages

- Reliable, high-capacity pile system

- Simple, low vibration installation

- Low risk for unanticipated performance

- Exterior grouted displacement installation for high frictional capacity

Design and Construction Solution

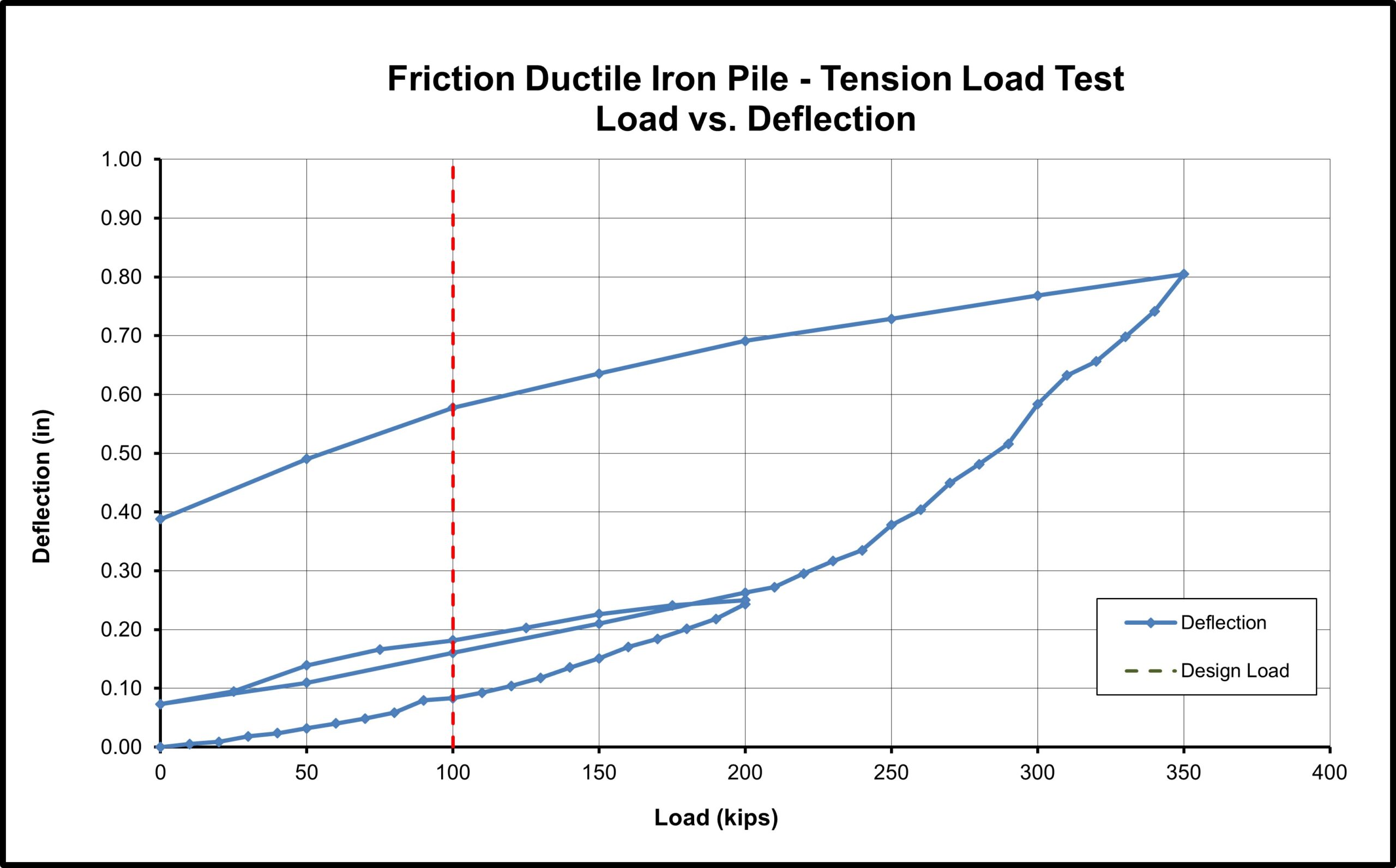

With successful load testing and implementation of Ductile Iron Piles on four previous projects at the base, the project team had a strong preference to use DIPs in the design for the new Headquarters Building. The design team contracted with Helical Drilling, Inc. to implement a pre-design load test program to verify the pile capacity. A full-scale tension load test was performed to verify the performance of the exterior grouted DIP developing capacity in friction. The test pile consisted of a Series 170/9.0 Ductile Iron Pile installed with a 270 mm (10.6 inch) diameter conical grout shoe. The test pile extended 32 feet (2 full 5-meter sticks) below grade. A 1-¾ inch diameter Grade 150 threadbar was wet-set in the pile to developstructural tension resistance for the test. The test was performed up to 200% of the 50 ton design load andunloaded. The test was then reloaded up to 350% of the design load (175 tons) to evaluate the behaviorat higher loads. The test was then unloaded and monitored for rebound. Results of the test showed theDuctile Iron Pile would deliver superior performance at the design capacity for the project.

Final design documents incorporated capacities of 50 ton (compression), 20 ton (tension) and 15 kip (lateral). The exterior grouted pile was designed to penetrate the undocumented fill and develop high frictional capacity through grout-to-ground bonding in the glacial sand below the fill. Anticipated pile lengths of 32 feet (2 sticks) were planned. A total of 218 production piles were included on the structural plans.

Phoenix Foundation Company, Inc. (Phoenix) was selected to perform the DIP installation on the project. Prior to production installations, Phoenix performed a pre-production, full-scale load test. Like the pre-design load test, results of the pre-production load test confirmed the design capacity for both compression and tension. Following completion of the test, Phoenix proceeded to install the 218 production piles across the site. Consistent pile lengths of 32 feet were used in all pile locations. Completion of this project represents the fifth project at the Quonset Business Park successfully designed, tested and installed with Ductile Iron Piles.

Project Team Members

Geotechnical Contractor: Phoenix Foundation Company, Inc.

Geotechnical Engineer: PARE Corporation

General Contractor:Gilbane Building Company

Structural Engineer: PARE Corporation