INTRODUCTION:

Construction of a new 2-story residence on the Island of Nantucket presents normal building challenges with material delivery and constrained site access. These challenges were further exacerbated when the initial engineering evaluation of the residential lot revealed uncontrolled fill and organics. The project required support for both building foundations and the nearby kidney-shaped swimming pool.

Geotechnical Conditions:

Borings encountered 18 feet of loose FILL and ORGANIC soils underlain by medium dense sand to depths of more than 40 feet.

Project Challenges:

Supporting a large 2-story, single-family residence and pool over fill and organics on a small coastal island where access to equipment and foundation solutions are limited.

Advantages

- Cost savings over traditional deep foundations

- Flexibility of installation from various grades and locations

- High capacity for reduction of scope

- Rapid installation

Design and Construction Solution:

The traditional over excavation and replacement was quickly ruled out considering the depth of fill and troubles of trucking spoils from the site through the residential development. Several types of piles were considered but presented challenges with transportation to the site. Ductile Iron Piles (DIPs) became a clear choice for foundation and pool support because of ease of transportation of the 16.4 feet (5 meter) long pile segments and high capacity of 50 kips.

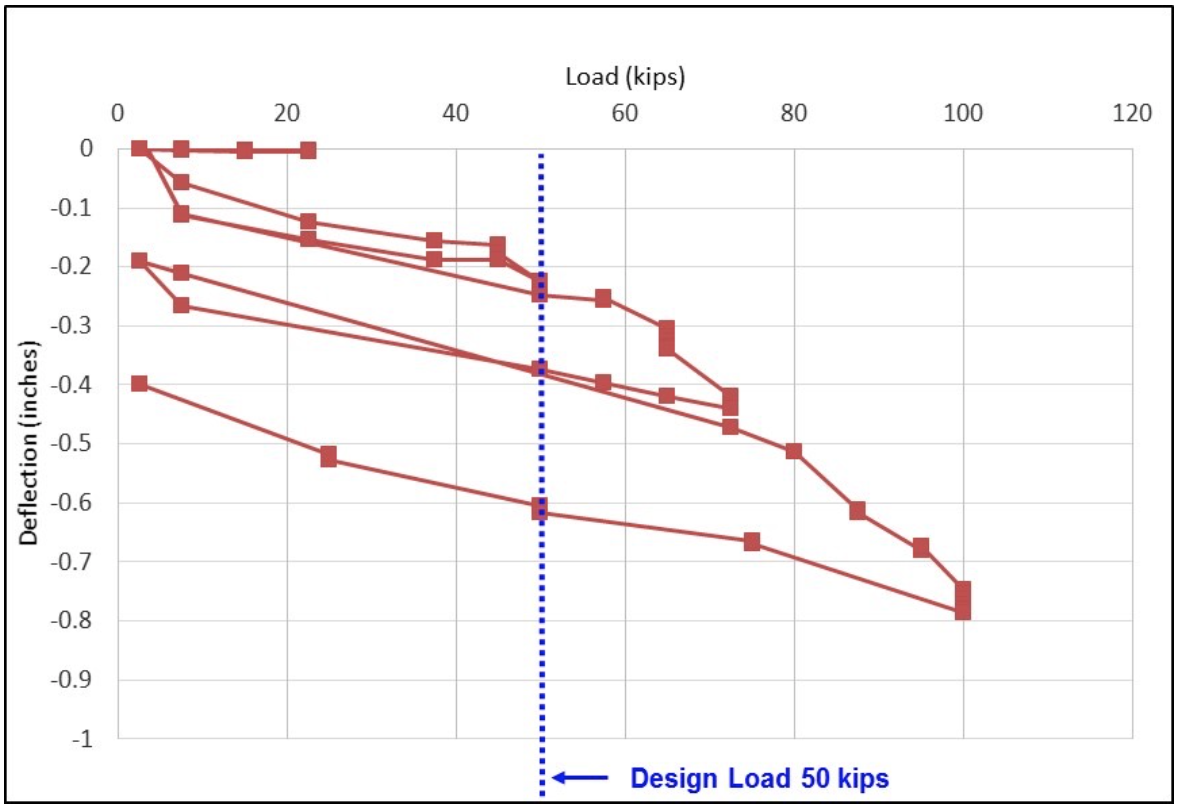

After overcoming normal transportation logistics to get materials and equipment to the island, the crew patiently backed up the tractor trailer 1.5 miles to access the site. Once there, a test friction pile was installed to a depth of 32 feet below the working grade. A bond length of 14 feet was used to develop a frictional working bond stress of 11 psi for design in the medium dense sand. A load test confirmed the design load and friction capacity with a factor of safety of two. Seventy four friction piles were installed in five days. The penetration rates with the sands in the bond zone closely matched the historically predicted driving rates.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: Paul Jenkins & Sons, Inc.

General Contractor: West Bay Development, Inc.

Structural Engineer: Veitas and Veitas Engineers, Inc.

Architect: Milton Rowland & Associates