INTRODUCTION:

The construction of a 15-story residential tower in the North Point area required a substantial raise in grade surrounding the residential building which was constructed on driven steel H-piles bearing on rock. Concerns regarding excessive settlement of sidewalks and landscape features from compression of fill and organic soils from the site grading drove the need for a positive support solution of a structural slab for these features.

Geotechnical Conditions:

Soil conditions explored by project geotechnical engineer, Haley & Aldrich, Inc. consisted of 24 feet of mixed debris FILL consisting of organic silt, clay, sand and silty sand with wood, concrete, brick and cinders underlain by 12 feet of very soft ORGANIC SILT. The FILL and ORGANIC SILT were underlain by dense SAND and hard MARINE CLAY and glacial TILL followed by bedrock. Groundwater was encountered at 6 feet below grade.

Project Challenges:

Develop a solution to control settlement of proposed landscape features following placement of substantial grade-raise fill.

Advantages

- Cost savings over traditional deep foundations

- Flexibility of installation from various grades and locations

- High capacity for reduction of scope

- Rapid installation

Design and Construction Solution:

In locations adjacent to the new building where substantial grade-raise fill was planned, the geotechnical consultant recommended that the concrete landscape structures and sidewalks be pile-supported to prevent long-term settlement of the organics and clay. Numerous deep foundation options were studied. Ductile Iron Piles (DIPs) were selected based on cost and flexibility of installation schedule. Flexibility of installation allowed additional time for the design of the landscape architecture to be fully developed.

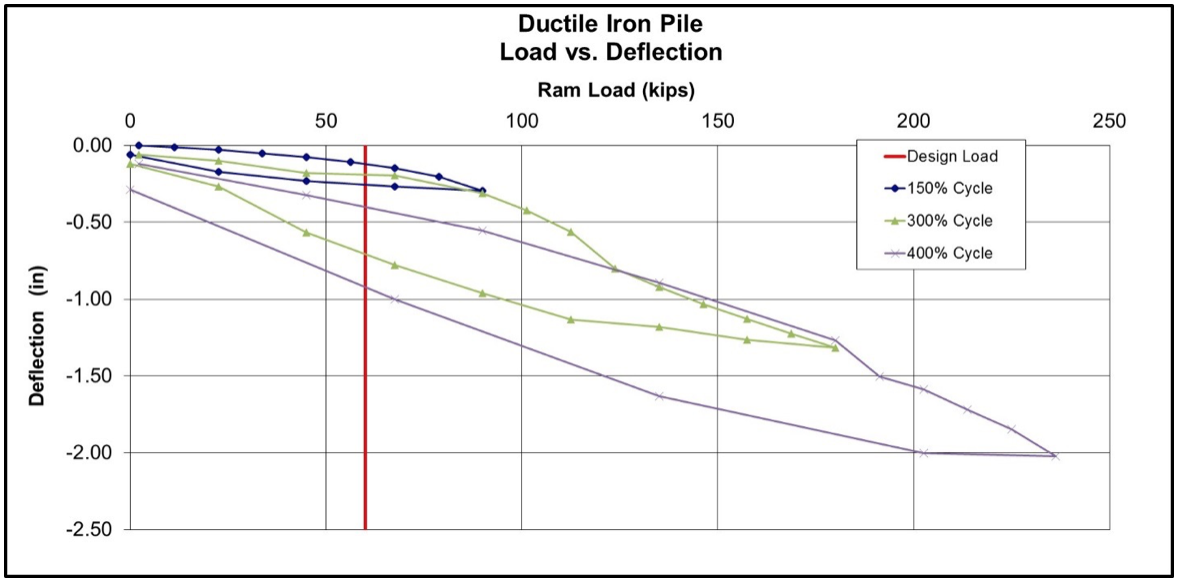

It was determined that 42 end-bearing DIPs were required support the design loads at a capacity of 60 kips per pile when terminating in the glacial till or on bedrock. The piles were driven using a mid-sized Volvo excavator fitted with a Tramac V1800 hammer to a set criteria of less than 1 inch in the last minute of driving. A load test was run to confirm the required design load with the factor of safety of two. Results at 60 kips (100% load) indicated a deflection of about 0.12 inches. After the initial load test cycle was complete, the pile was reloaded to 300% (180 kips) and then 400% (236 kips) of the design load to evaluate performance at higher loads. The test results confirm that the Type 118 (4 5/8 diameter) pile is capable of supporting loads well in excess of 100 kips.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: Haley & Aldrich, Inc.

General Contractor: John Moriarty & Associates, Inc.

Structural Engineer: McNamara Salvia

Architect: CBT Architects