INTRODUCTION:

INTRODUCTION:

Construction involved redevelopment of a single-story retail space immediately adjacent to an existing single-story retail building. Foundation loads were 93 to 177 kips and wall loads ranged from 2.5 to 15 kips per foot.

Geotechnical Conditions:

Soil conditions consisted of up to 6 feet of loose to medium dense silty sand fill and loose native silty sand to depths of about 10 feet. One boring encountered a 2 foot thick layer of soft peat below the fill. Very loose to medium dense silty sand with SPT N-values generally ranging from 2 to 6 bpf were then encountered to the maximum exploration depth of 29 feet. Groundwater levels ranged from 8 to 10 feet below grade.

Project Challenge:

- Providing foundation support with minimal vibrations immediately adjacent to existing foundation line.

Advantages

- Cost savings over traditional helical piles

- Limited vibrations immediately adjacent to existing buildings

- Rapid DIP installation

- Compatibility with Geopier® Ground Improvement used elsewhere on site

- Significant cost savings over traditional H-piles and drilled micropiles

Design and Construction Solution:

The loose fill and native sand conditions were ideal for a cost-efficient Geopier® ground improvement solution to support shallow foundations and control settlement. However, the proximity of the new building immediately adjacent to the existing structure presented issues with access, excessive vibrations and the potential for settlement of the existing structure. The project team initially considered helical anchors designed in the loose sand with a capacity of 27 kips. Working with the owner and structural engineer, Helical Drilling and DuroTerra proposed a Ductile Iron Pile design using a working capacity of 40 kips and reduced the number of piles by 25%. Both pile options were competitively bid and the Ductile Iron Piles were selected.

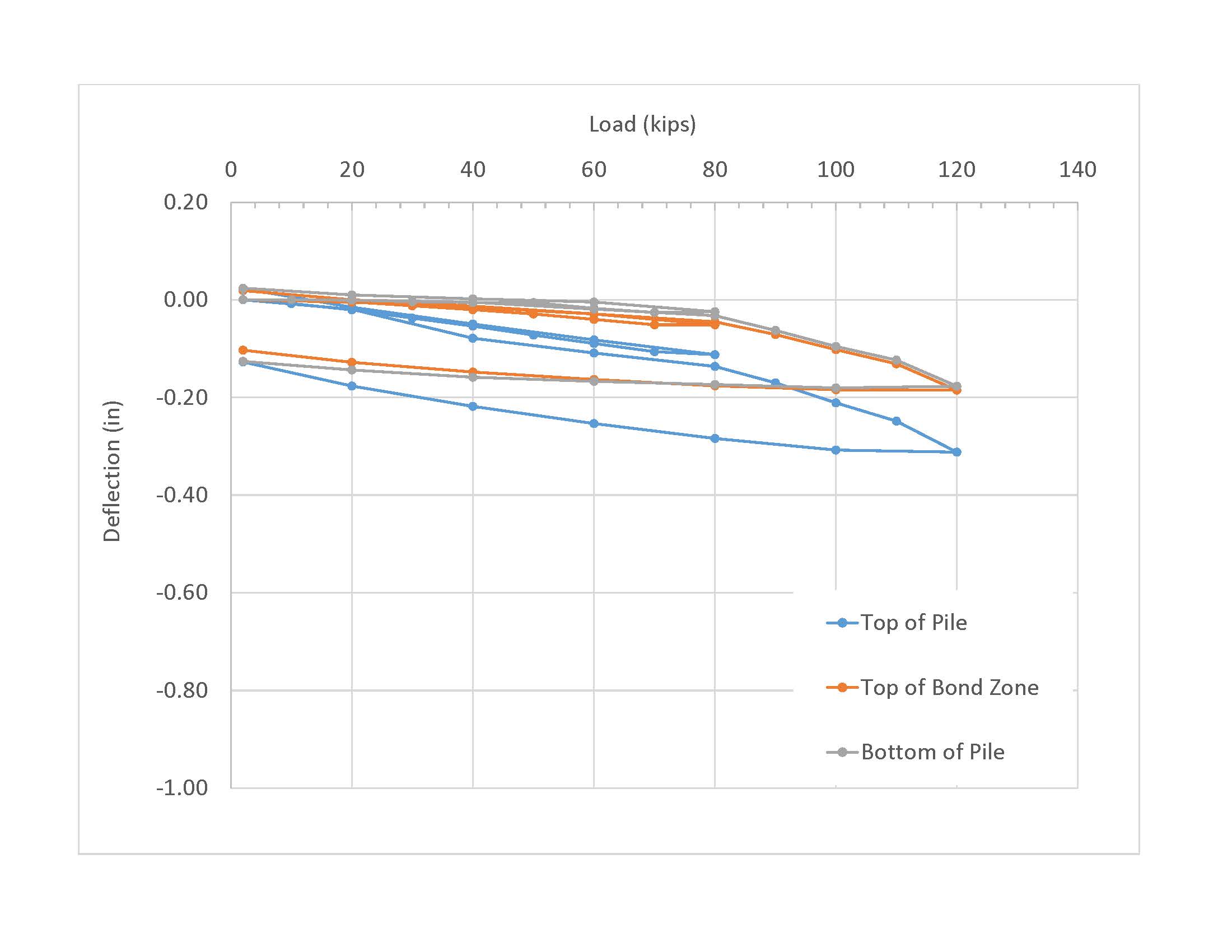

A total of 39 Ductile Iron Piles were installed along the building line adjacent to the existing building. The Series 118/7.5 piles were designed as friction piles using a 220 mm diameter conical grout cap to construct a bond zone in the very loose to loose sand. Load testing performed on a sacrificial pile extending to a depth of about 32 feet in the loose conditions showed movement of less than 0.15 inches at 80 kips (200%). The test was completed and then cycled up to a load of 120 kips (300%) and recorded deflections of only 0.31 inches – a superior response under loading for the friction pile in loose conditions. Permanent (non-recoverable) deflection after loading to 300% was less than 0.2 inches.

Helical Drilling performed installations of both the Geopier system and the Ductile Iron Piles for complete foundation support at the site. Production pile installation was completed in only 3 working days – working adjacent to the existing building. Vibration monitoring performed during installation recorded peak particle velocities of of less than 0.2 inches/second at close distances from installations.

Project Team Members:

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: Terracon, Inc.

General Contractor: National Contractors, LLC

Structural Engineer: RKW Engineering, PC

Architect: APD Engineering & Architecture, PLLC