CONTRACTOR SPOTLIGHT – Phoenix Foundation Company, Inc.

![]() As we continue our DuroTerra Contractor Spotlight, we turn your attention back to the Northeast U.S. where our friends at Phoenix Foundation Company, Inc. operate out of Uxbridge, Massachusetts. Phoenix Foundation Company, Inc. (Phoenix) was started in 2018 and specializes in a variety of geotechnical construction techniques including deep foundations (drilled micropiles, drilled shafts, Ductile Iron Piles, helical piles, etc), temporary and permanent earth support (drilled soldier piles with tiebacks/bracing, soil nailing), and a number of grouting applications (pressure, chemical, compaction, jet, etc). Phoenix serves all of New England and parts of New York. “Phoenix strives to innovate the way in which specialty geotechnical subcontracting is performed. We value relationships over revenue, and believe that conducting business with integrity and purpose will ultimately set us apart from the competition,” says Bob Tonning, P.E., President of Phoenix.

As we continue our DuroTerra Contractor Spotlight, we turn your attention back to the Northeast U.S. where our friends at Phoenix Foundation Company, Inc. operate out of Uxbridge, Massachusetts. Phoenix Foundation Company, Inc. (Phoenix) was started in 2018 and specializes in a variety of geotechnical construction techniques including deep foundations (drilled micropiles, drilled shafts, Ductile Iron Piles, helical piles, etc), temporary and permanent earth support (drilled soldier piles with tiebacks/bracing, soil nailing), and a number of grouting applications (pressure, chemical, compaction, jet, etc). Phoenix serves all of New England and parts of New York. “Phoenix strives to innovate the way in which specialty geotechnical subcontracting is performed. We value relationships over revenue, and believe that conducting business with integrity and purpose will ultimately set us apart from the competition,” says Bob Tonning, P.E., President of Phoenix.

Phoenix has successfully installed Ductile Iron Piles on projects in New England for many years. “We have found DIPs to be viable on many different projects. They can be competitive against both driven and drilled foundation alternatives on a variety of open and restricted project sites,” notes Tonning. Phoenix has found DIPs offer real advantages including high production rates, elimination of drill spoils, efficient use of the material with little to no waste and valued customer support offered by DuroTerra.

Phoenix installed DIPs on recent projects at both Boston College and MIT. “The DIP’s ability to be installed quickly with varying capacities worked as an excellent solution to meet the need for structural elements in relatively confined sites and compressed schedules. In addition to being a cost-effective solution, the minimal support required from the GC or other trades is also a significant benefit. Both projects were successfully completed safely and on schedule,” says Shane O’Neill, Operations Manager for Phoenix.

Please continue reading for more information about a project where Phoenix delivered a DIP solution that saved money against displacement micropiles and reduced the project schedule for their customer. For more information about Phoenix Foundation Company, Inc., visit phoenixfoundationcompany.com.

INTERESTED IN BECOMING A DUCTILE IRON PILE INSTALLER?

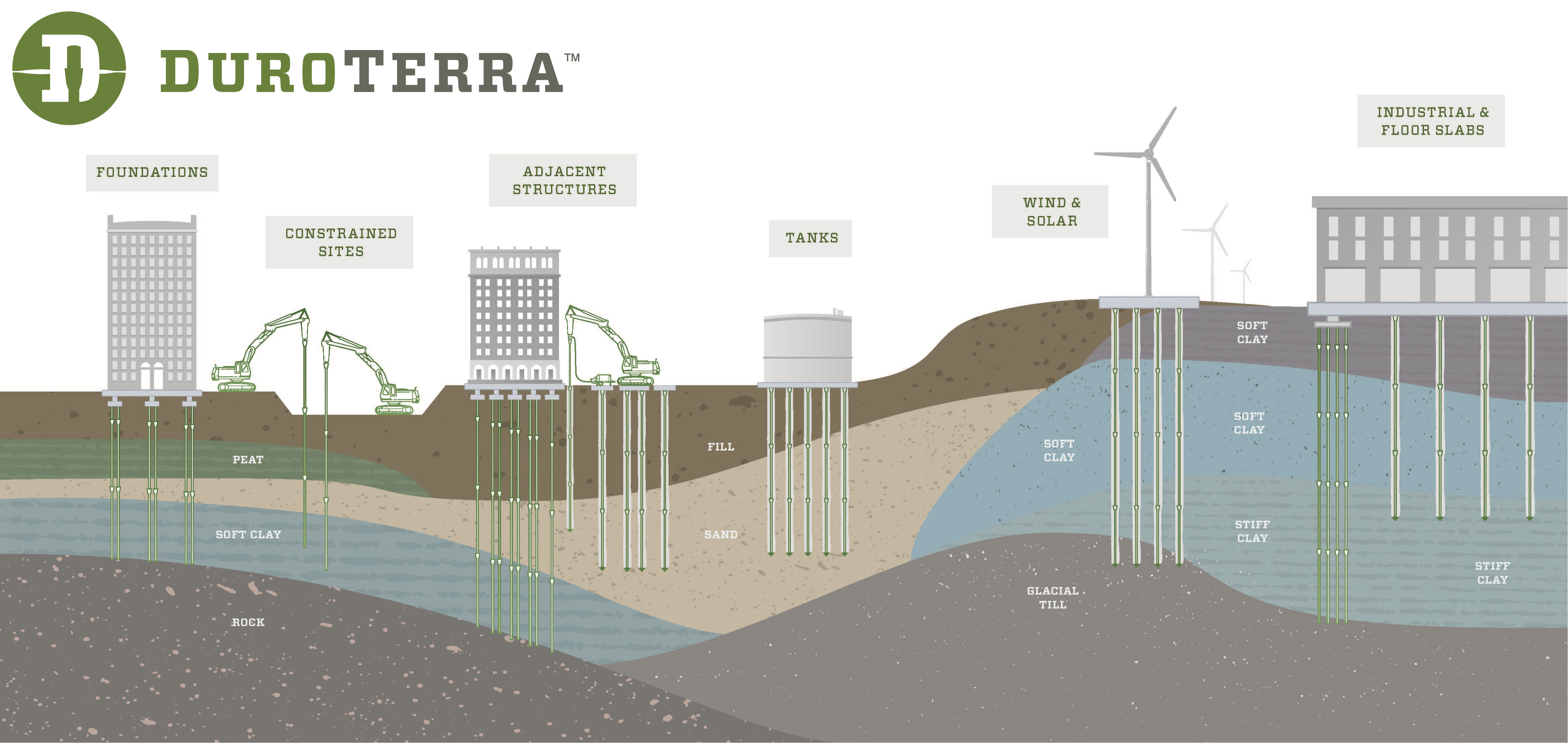

DuroTerra works with a wide variety of geotechnical contractors across the U.S. and Canada – from local contractors to international geotechnical contractors on projects of all sizes. Our engineering and construction representatives can guide you with product information, equipment assessment and setup as well as project feasibility and pricing. Reach out to us today to learn more.

PROJECT HIGHLIGHT – Stack Street Pavilion at Hood Park Redevelopment, Boston, MA

The Stack Street Pavilion is a part of the larger Hood Park redevelopment effort featuring mixed-use, residential and commercial space in Boston, MA. The project includes an elevated green space, pedestrian bridge and single-story pavilion area. Due to the presence of urban fill and organics as well as a planned future adjacent excavation, deep foundations were required to transfer the building loads to competent soils below the fill and organics and be designed to resist buckling from reduced confinement from the nearby excavation.

The urban fill and organics extended to 22 feet below grade and were underlain by marine and glaciomarine sand and clay. Medium dense to dense glacial till was then encountered at 38 feet. Geotechnical engineers needed a solution to address the noted design aspects as well as to provide low vibrations and cost efficiency. Considerations were given to drilled micropiles, driven piles, proprietary displacement/helical piles and ductile iron piles. The ductile iron piles were ultimately selected based on high production rates, limited lead time for material and cost-savings.

Phoenix Foundation Company, Inc. used an Atlas Copco MB1700 percussion hammer on a Kobelco SK230SR excavator to install 8.5-inch diameter exterior grouted Ductile Iron Piles. A Series 118/9.0 pile was installed with an oversized 220 mm (8.6-inch) diameter grout shoe while continuously pumping a sand-cement grout to construct the grouted displacement piles. Piles were advanced to depths of about 40 feet to construct an 18-ft bond zone below the fill and organics and achieve a design capacity of 40 tons. Load testing performed to 225% of the design load showed only 0.33 inches of deflection and confirmed transfer of 150% of the design load to the bond zone as required by the MA State Building Code.

Following successful load testing, Phoenix installed 128 production piles in 9 working days. With an average of 15 piles per day (600 LF/day), installation was much faster and simpler than a traditional micropile, allowing Phoenix to reduce the planned pile schedule by half. To learn more about the project, check out the full project summary.