DuroTerra Dialogue: A low-vibration, driven piling system…

A low-vibration, driven piling system…

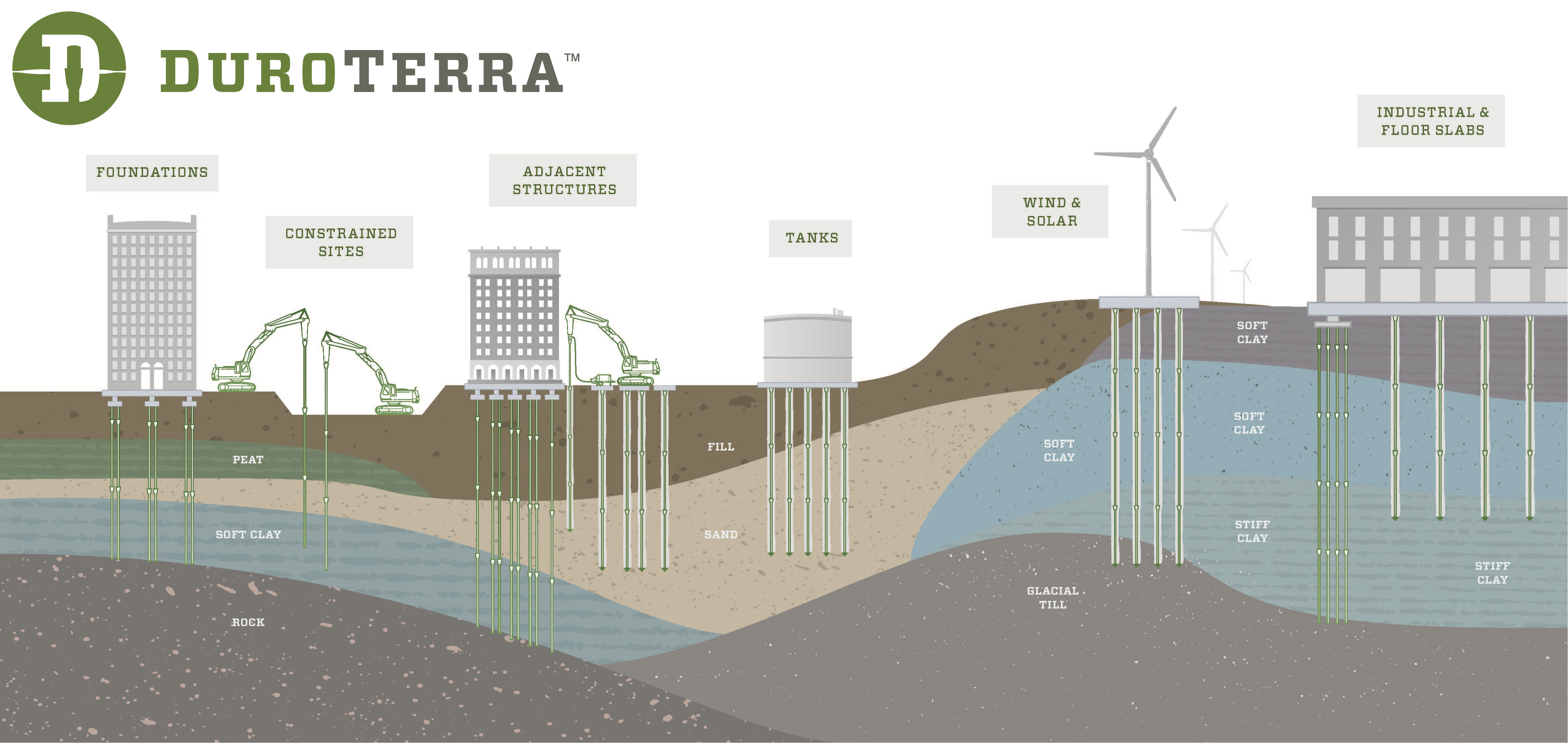

The low vibration levels combined with the ability to install Ductile Iron Piles in limited overhead areas or on constrained sites adjacent to existing buildings have made DIPs a preferred option for many projects. Check out a couple of the projects where minimizing vibrations contributed to the successful incorporation of Ductile Iron Piles. Looking for a cost-effective, low vibration option on your project? Reach out for a feasibility assessment by one of our engineers.

Relevant projects

Plans for a new 161,000 sqft movie studio required foundation and retaining wall support abutting an existing, vibration-sensitive retaining wall on a portion of the site. While ground improvement was planned for the majority of the project, Ductile Iron Piles were selected to limit vibration concerns in the critical areas. Grouted Ductile Iron Piles were installed through the fill and organic clay to develop working capacities of 40 tons (compression) and 19 tons (tension) through friction in the underlying medium dense to dense sand. Following successful load testing, a total of 195 piles were installed in 11 working days with no impacts to the retaining wall.

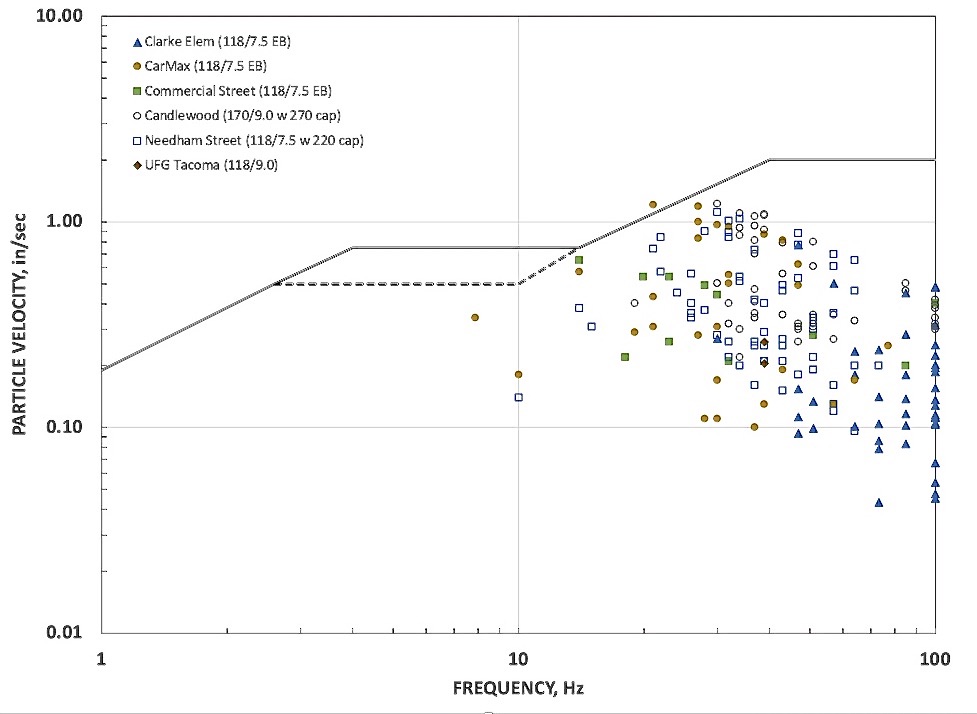

Vibration concerns raised during ground improvement installation at the site of a new 5-story parking garage drove the need for a low vibration solution supporting foundations abutting the neighboring existing building. Foundation loads were up to 900 kips in this area. The project team opted for a low vibration driven Ductile Iron Pile solution to provide a 65 ton pile installed to rock at depths of 30 to 40 feet. Maximum vibration levels measured only 0.26 in/sec at a distance of less than 10 feet from pile installation – well within the 0.4 in/sec threshold. A full-scale load test was used to verify performance and showed less than ¼-inch deflection at the design load of 65 tons. A total of 44 piles were installed for support of the pile caps.