Manufacturing Process

Advanced Techniques

Ductile Iron Piles are comprised of grey cast iron, which has been used for commercial pipeline construction since the early 1800s.

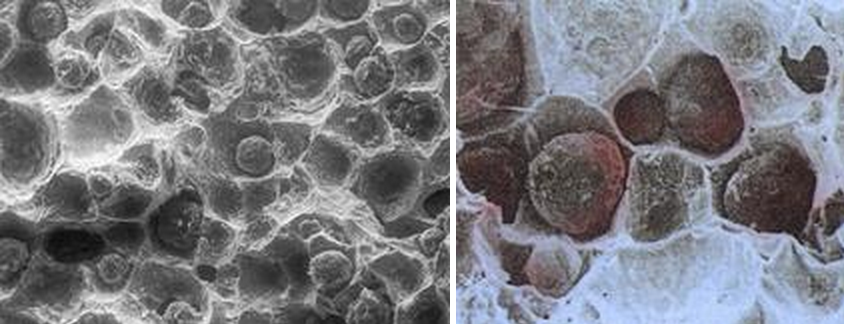

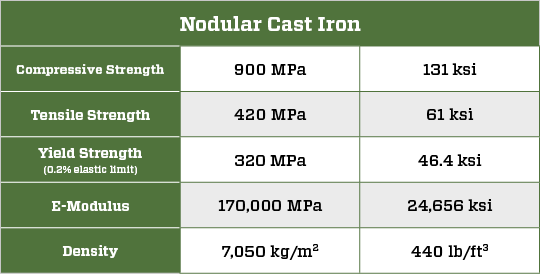

Historically, cast iron or grey cast iron was produced in a lamellar form. The material was often brittle and exhibited low strength and impact resistance. Advancements over a half-century ago led to the development of spheroidal or ductile cast iron by adding magnesium to the cast iron before pouring to produce crystallization of graphite in spheroidal form (Figure 2). The development of spheroidal graphite cast iron led to more desirable material properties including improvements in the ultimate and yield strength, tensile and flexural strength, improved impact resistance for drivability and toughness, while maintaining cast iron qualities including machinability and cast-ability.

Spheroidal Graphite (Ductile Iron) Detail

During manufacturing of the Ductile Iron Piles, the ordinary grey or lamellar graphite undergoes a sophisticated manufacturing process that transforms it into spheroidal graphite or ductile cast iron. This process drastically improves the cast iron’s impact resistance, ductility, tensile strength and flexural stiffness.

The ductile cast iron material used in the piles contains a high recycled content and is comprised of: 90-95% scrap metal iron, approximately 3.7% carbon, and approximately 2.7% silicon.

Ductile Iron Piles are manufactured by Tiroler Rohre GmbH (TRM) in Austria. Ductile cast iron used in the fabrication of the piles undergoes a sophisticated centrifugal- or spun-casting manufacturing process to transform the raw recycled material into the finished product. The ductile iron piles are factory prefabricated to precise tolerances. Standardization results in the materials being subject to strict control of its chemical composition and its mechanical properties throughout the fabrication process.

Download the Manufacturer Brochure

The manufacturing process employs a quality assurance system that is certified in compliance with ISO 9001:2000 “Quality Management Systems”. Further, a variety of other European inspections and certifications are deployed at key stages throughout the manufacturing process to provide regular control of the product and prefabrication process:

- Standard BS EN 10204 inspection process

- ONCERT certification (ONR 22567 regulation)

- European Technical Approval (ETA-07/0169)