Quality Control

Results-driven Excellence

Despite the ease of installation of the Ductile Iron Piles, successful performance of the system relies closely on the level of quality control and testing undertaken during installation. The quality control / quality assurance activities consist mostly of monitoring items such as penetration depth, penetration rate, set criteria, grout pump strokes and termination depths. Full-scale load testing to verify capacity is also an important quality control aspect for the system.

Driving and Driving Rates

Quality control during DIP installation is largely focused on monitoring pile penetration and penetration rates during driving. Each section of Ductile Iron Pile is factory-marked in one meter increments to assist with monitoring the length of time required to drive 1 meter of pile into the ground. The rates of penetration are used as indicators of geotechnical resistance and pile capacity. For piles developing capacity in friction, the drive rates provide confirmation that the pile is penetrating into the competent bonding strata. For piles developing the capacity in end-bearing, the drive rates are measured (seconds/inch) to verify the adequate “set” criteria is achieved. Drive rates are monitored for both End-Bearing piles and also Friction Piles.

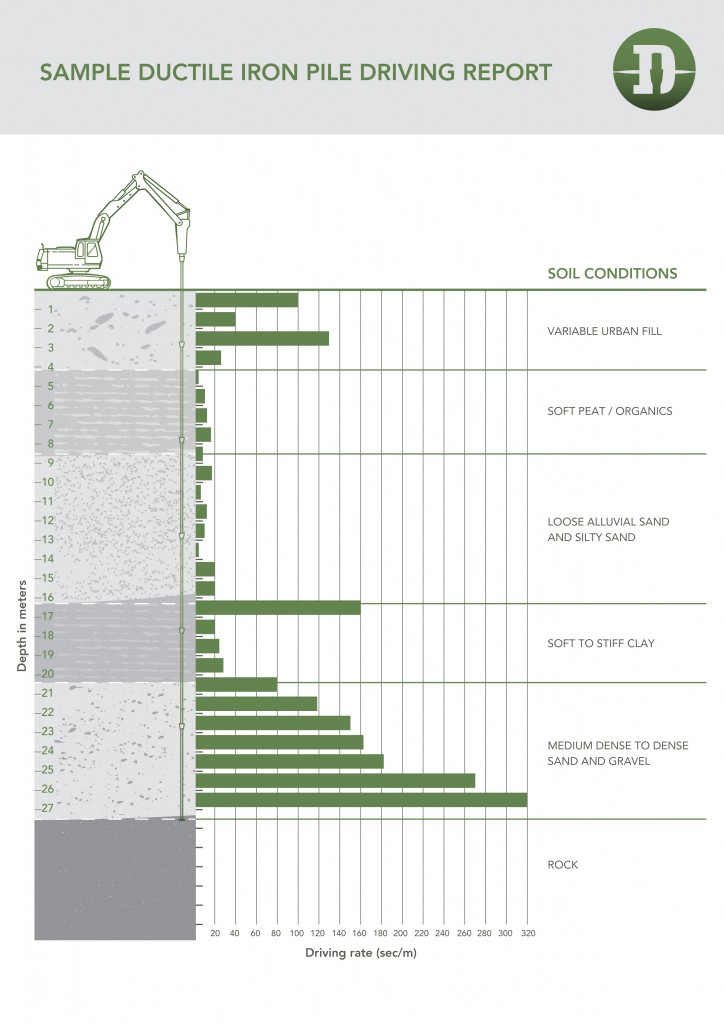

The figure below shows an illustration of driving rates with depth that is obtained for a pile.

The rate of penetration for Friction Ductile Iron Piles is used real-time during pile installation to determine the depth at which the bond layer (competent layer in which the bond zone is developed) is encountered. This is based on noting a marked increase in the driving resistance that is consistent with the anticipated depth of the bond layer. The pile is then driven a specified depth into the better layer based on the design requirements.

Depth of Termination

For End-Bearing Piles, the depth of termination is determined based on either refusal on a hard layer (rock) where further penetration or advancement of the pile is not feasible. Alternatively, piles may be terminated when a “set” criteria is met. The “set” criteria is defined as a limited amount of deflection observed while driving the pile for a particular time limit. Decades of installation and verification testing indicate that a “set” criteria of 1 inch or less of penetration in 50 seconds or longer is adequate to achieve the design geotechnical capacity for most design cases. Project-specific variations to set criteria are often made and established based on site-specific load testing.

Friction Ductile Iron Piles are not designed to be installed to a refusal layer or a specific “set” criteria. Instead, the grouted elements are designed to advance a particular depth into a competent strata to develop sufficient bonding length to generate the required design capacity through friction. Early refusal or “set” of a friction pile may still be acceptable for a compression pile depend on the design requirements.

Load Testing

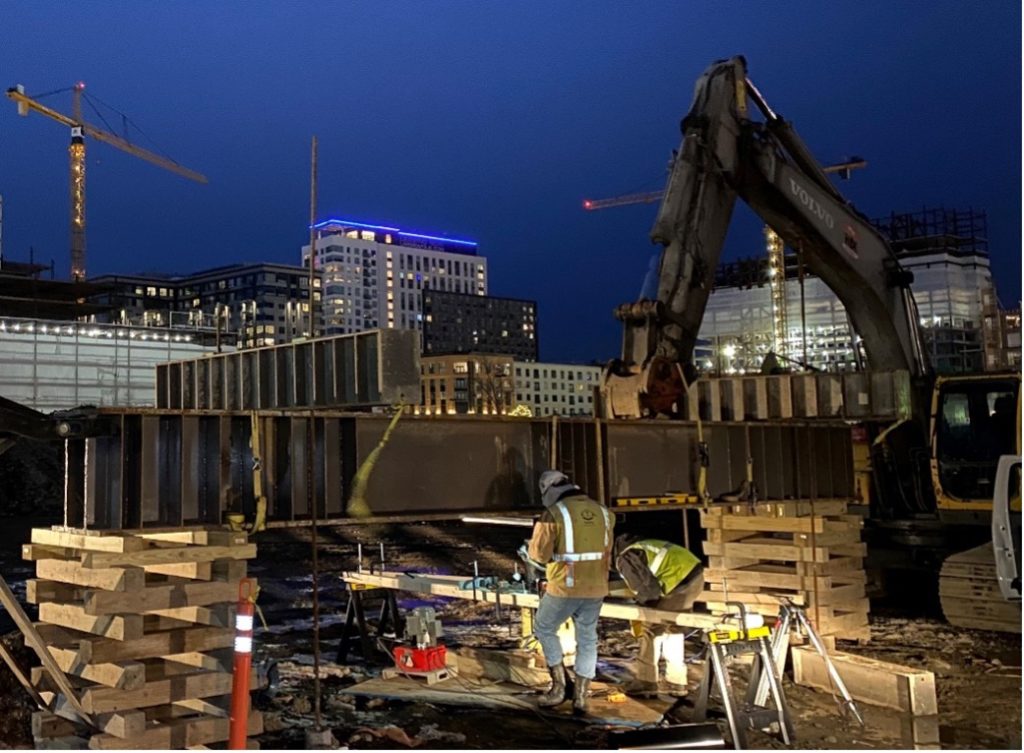

Load testing is an important tool for verifying capacity of both End-Bearing and Friction piles. Load testing for end-bearing applications is performed in general accordance with ASTM D-1143-07 for static load testing of pile foundations (see load test picture). Alternatively, load testing for Friction piles may be performed in either compression in general accordance with ASTM D-1143-07 or in tension in general accordance with ASTM D-3689-07 to evaluate axial tensile load testing of piles (see load test picture). Tension testing is often an acceptable means to test the bond zone resistance for either tension or compression loads. It is often a preferred method for testing because it eliminates the need for numerous high capacity tension reaction anchors for a compression load test frame.

Ductile Iron Piles are typically load tested to 200% of the design load depending on project requirements. Local building codes establish the testing requirements and should be followed. The specific increments for loading often range from 10% to 25% of the design load depending on the standard with durations at each load ranging from 4 minutes to 60 minutes. A creep load is typically applied at 200% of the design load and maintained for a minimum of one hour and until the deflection is less than 0.01 inch/hour or 4 hour passes.

The results of the load tests are used to verify the design capacity of the Ductile Iron Pile. Many options for load test interpretation are used in the pile industry including the Davisson Offset, Brinch-Hansen Method and the Butler-Hoy Criteria. Determination of the acceptance requirements need to rely on the project performance specifications or local code interpretation.

Grout Testing

Grout testing is often performed to verify that the grout strength reaches the minimum design requirement. For neat cement grout, often used to fill the interior of non-grouted piles, grout cubes are made during the grouting operation. For sand-cement grout used during the installation of grouted piles, it is recommended to use 4” x 8” concrete cylinders as the most representative test to evaluate the strength of the mix.