Ductile Iron Piles provided a low vibration, deep foundation system to support the building loads on the highly variable site.

Project Description:

Construction at 42 Spinelli Place consisted of a new single-story building to house laboratory space, conferencerooms and office space. Column loads for the building ranged from 73 to 193 kips. The building was positioned immediately adjacent to an existing building. In addition, an historic sewer was located within 5 feet of the new building footprint.

Geotechnical Details:

Soil conditions varied significantly across the site. Conditions consisted of granular fill with depths of 13 ft to 27 ft below current grades. The fill was underlain by an organic deposit (peat, organic silt/clay) that ranged in thickness from 0 to 22 feet. An approximate 10-ft thick deposit of clay and silt was found beneath the organics across most of the site. In all borings, below the organics and silt/clay, medium dense to dense sand and gravel was encountered to the maximum depths of the borings. Groundwater was generally about 5 to 10 feet below grade.

Project Challenges:

Provide a low vibration, deep foundation system to support the building loads on the highly variable site.

Advantages

- Rapid installation on a highly variable site.

- Low vibration installation to limit impacts on adjacent buildings and existing utilities.

- High level of quality control using drive rate monitoring to confirm penetration of fill and organics and start of bond zone.

- Multiple load tests to confirm the 40 ton compression capacity.

Design and Construction Solution

Geotechnical engineers recognized the substantial challenges presented by the variable ground conditions at the site. The foundation system needed to 1) support the structural loads, 2) minimize vibrations that could be harmful to the adjacent building and nearby utilities and 3) implement an installation procedure addressing the significant site variability to reduce the potential for installation and performance issues. After weighing other foundation options including PIFs and ground improvement, the project team selected Ductile Iron Piles. The low vibration piling system had a track record for supporting loads ranging from 25 to 100 tons per pile. Further, the QA/QC program of monitoring drive rates during installation would be an important quality control check to confirm each pile penetrated the highly variable thicknesses of fill and peat and terminated at sufficient depths into the sand.

Geotechnical engineers recognized the substantial challenges presented by the variable ground conditions at the site. The foundation system needed to 1) support the structural loads, 2) minimize vibrations that could be harmful to the adjacent building and nearby utilities and 3) implement an installation procedure addressing the significant site variability to reduce the potential for installation and performance issues. After weighing other foundation options including PIFs and ground improvement, the project team selected Ductile Iron Piles. The low vibration piling system had a track record for supporting loads ranging from 25 to 100 tons per pile. Further, the QA/QC program of monitoring drive rates during installation would be an important quality control check to confirm each pile penetrated the highly variable thicknesses of fill and peat and terminated at sufficient depths into the sand.

A Series 118/7.5 Ductile Iron Pile was designed to develop the 40 ton (compression) capacity included in the structural engineer’s plans. The piles were designed with an oversized 220 mm (8.6 inch) diameter conical grout shoe to construct an 8-inch diameter exterior grouted friction pile. The piles were designed to penetrate through the fill and organics and terminate a minimum of 19 feet into the sand layer. Estimated pile lengths ranged from 32 to 62 feet based on the depths to the bonding layer from the borings. A total of 87 piles were planned.

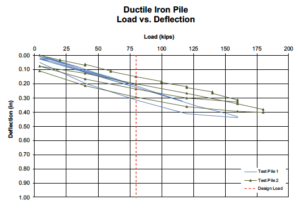

Prior to the start of production piles, Helical Drilling installed two test piles on the site. Test Pile 1 was located on the western portion of the site. The pile advanced through variable “urban” fill and very soft organic soils to depths of about 47 feet where slower drive rates were recorded. The pile was then advanced 19 feet into the granular soils to generate bond capacity with an overall length of 66 feet. Test Pile 2 was installed on the eastern portion of the site. The pile encountered “urban” fill to about 22 feet followed by stiff silt and sand and was terminated at a length of 40 feet. The results of both tests performed to 200% of the design load (160 kips) showed less than 0.43 inches of total movement with 0.11 inches of net deflection on rebound.

Prior to the start of production piles, Helical Drilling installed two test piles on the site. Test Pile 1 was located on the western portion of the site. The pile advanced through variable “urban” fill and very soft organic soils to depths of about 47 feet where slower drive rates were recorded. The pile was then advanced 19 feet into the granular soils to generate bond capacity with an overall length of 66 feet. Test Pile 2 was installed on the eastern portion of the site. The pile encountered “urban” fill to about 22 feet followed by stiff silt and sand and was terminated at a length of 40 feet. The results of both tests performed to 200% of the design load (160 kips) showed less than 0.43 inches of total movement with 0.11 inches of net deflection on rebound.

Production piles were installed over a 9 day period. Pile lengths ranged from 36 to 79 feet with an average length of 55 feet. Production rates averaged over 550 LF/day and were as high as 1,000 LF on some days. Vibration monitoring during the installation confirmed that peak particle velocities were no greater than 0.75 ips within 5 feet from pile installation indicating acceptable levels for both the adjacent building and utility line.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: GZA GeoEnvironmental, Inc.

General Contractor: Sea-Dar Constructions

Structural Engineer: LeMessurier