Introduction:

The project involved support of a new 175-foot long Contech pedestrian bridge as a part of the Cheney Rail Trail with support provided by abutments located on the North and South (former railroad) embankments. Abutments measuring 8-ft wide and 16-ft long were loaded to 18.6 kips per foot vertically and 1.3 kips per foot laterally.

Geotechnical Conditions:

The subsurface conditions at the abutment locations generally consist of undocumented sand FILL (former railroad embankment material) extending to depths of 45 to 47 feet underlain by medium dense to very dense native sand to the maximum explored depth. Groundwater was expected to be below the depth of the fill.

Project Challenge:

Providing cost-effective deep foundation support at a constrained greenfield work site atop an existing embankment with installation locations separated by a ravine.

Advantages

- Ability to work in tight access with medium-sized excavator

- Modular system for ease of installation to depth atop an embankment

- Rapid installation

Design and Construction Solution:

Plans for the Cheney Rail Trail over Bigelow Brook initially specified culvert replacement near Edgerton Street followed by backfilling to connect the north and south embankments along the former rail line. Cost-saving design modifications converted the culvert/grade-raise to a pedestrian bridge with abutment footings bearing atop the embankments. The changes also precluded the use of the originally-specified Geopier® ground improvement solution for foundation support because of the increased treatment depths requiring full penetration of the embankment.

Working with Helical Drilling, Inc., the project team selected a Ductile Iron Pile as a cost-effective deep foundation solution for bridge abutment support. The modular Ductile Iron Pile system uses mobile equipment that could easily access the abutment locations on top of the existing embankments. Installation with the 5 meter (16.4 ft) bell-spigot pile sections easily handled the depth requirements exceeding 50 ft.

Friction Ductile Iron Piles were selected for foundation support. A 118/7.5 series pile (118 mm outer diameter with 7.5 mm wall thickness) was used along with an oversized 220 mm conical grouting shoe. Sand-cement grout was pumped as the pile was driven into the ground using a high frequency, low vibration percussion hammer. The grout is tremied through the base of the pile and completely encapsulates the pile in the annular space created by driving the oversized grout shoe. The end result is a low vibration, friction pile that develops capacity using a high-strength grouted bond zone below the fill.

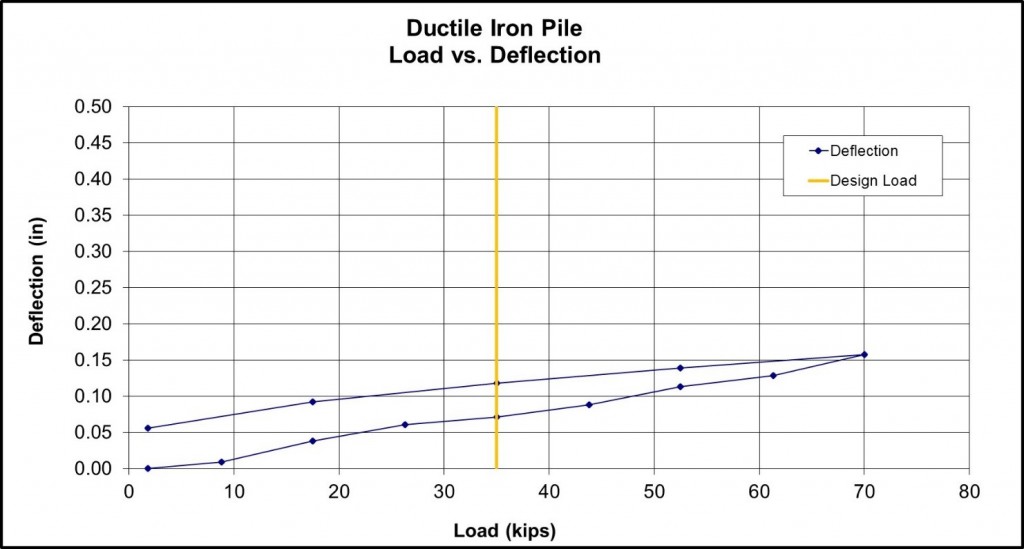

A total of 16 piles were installed approximately 55 feet beneath each abutment to support the vertical and lateral loads. Piles were installed in 2 working days. Site-specific load testing performed up to 70 kips confirmed design capacities and showed less than 0.20 inches of total movement at the maximum test load and 0.06 inches of net deflection at the end of the test.

Project Team Members:

DIP Design/Build Partner: Helical Drilling

Owner: Town of Manchester

Geotechnical Engineer: Weston & Sampson Engineering

General Contractor: Pondview Construction, Inc.

Structural Engineer: Weston & Sampson Engineering