Introduction:

Extensive development in the vicinity of the new Downtown North Hartford Baseball Stadium includes the site of a new 8-story, 53,400 square foot Candlewood Suites hotel. Foundation loads for the steel-framed structure range from 400 to 800 kips with areas of isolated tension demand on braced-frame footings.

Geotechnical Conditions:

Subsurface conditions at the site included up to 8 feet of variable, debris fill underlain by soft to stiff silt and sandy silt to a depth of about 22 feet. A medium dense to dense sand layer was encountered below the silt until shale bedrock was encountered at depths of 25 to 32 feet below grade. Groundwater was about 15 feet below grade.

Project Challenges:

Providing cost-effective deep foundation support for both compression and tension loads.

Advantages

- High capacity (100 ton) compression resistance to replace H-piles

- Rapid installation

- Easily adjusts to varying rock depths

Design and Construction Solution:

Initial recommendations and design for the project utilized 100 ton driven H-piles (HP 12×74 or HP 14×73) to support the building loads. Helical Drilling proposed a value engineered alternative utilizing Ductile Iron Piles as a replacement to the specified H-piles. The driven Ductile Iron Piles solution provided a 1:1 replacement with the 100 ton working capacity H-piles and were selected to save foundation costs and schedule.

The 100 ton Ductile Iron Piles consisted of a 170/9.0 (170 mm diameter with 9 mm wall thickness) with 4,000 psi neat cement grout and a high-strength #9 reinforcing bar installed in the center. In areas where tension loads of up to 36 kips (ultimate) were required, an oversized 270 mm conical grouting cap was installed on the 170/9.0 piles. During installation, sand cement grout was pumped to fill the annular space created by the oversized cap and develop a friction bond zone in the sand and silt layers.

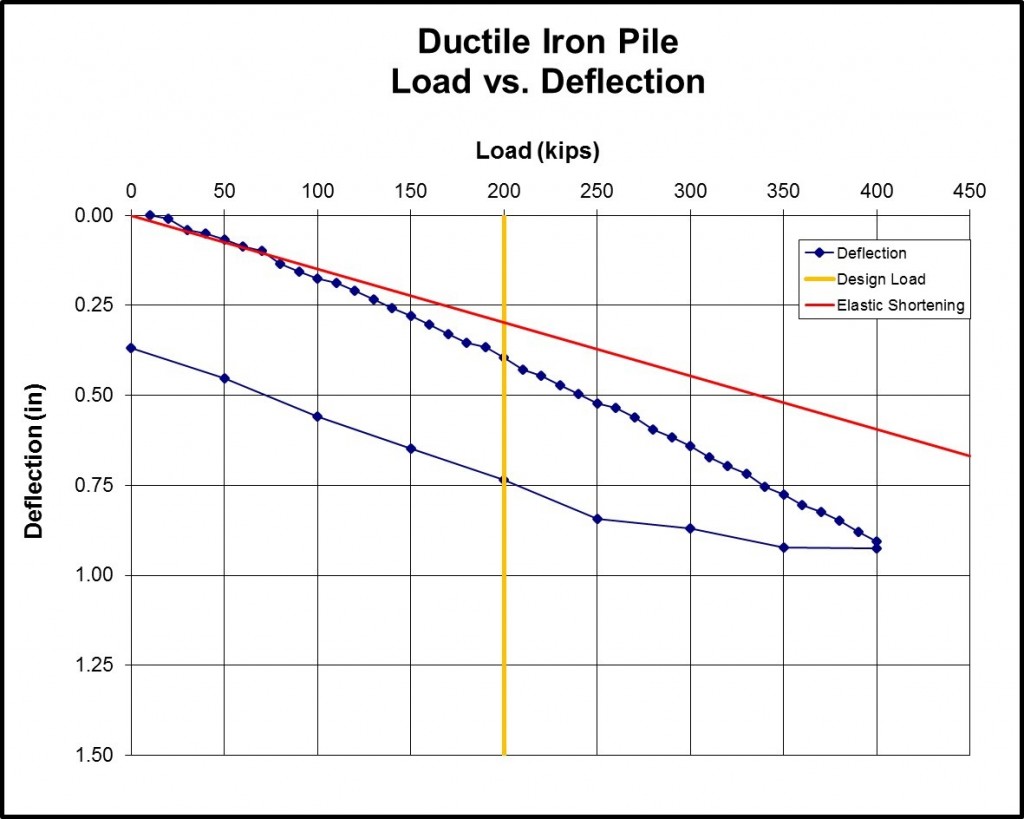

Compression load testing was performed to 200% of the design load (400 kips). Results showed about 0.4 inches of movement at the 100% design load (200 kips) and about 0.9 inches at the 200% design load (400 kips). Permanent net deformation of less than 0.4 inches was recorded. The pile was then reloaded and tested to more than 500 kips to evaluate the response at even higher loads. Reactions for the test consisted of 8 friction DIPs to also verify the tension capacity.

A total of 124 piles were installed on the project with 32 of the piles developing tension resistance with an oversized conical grout shoe. All piles were installed through the silt and sand to bear on the rock. Termination of the piles occurred when a “set” criteria of less than 1 inch of penetration in 50 seconds was achieved. The piles were installed by Helical Drilling in only 12 working days on the site.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: Clarence Welti Associates, Inc.

General Contractor: PM Construction Company

Structural Engineer: Structural Design Associates, Inc.