Ductile Iron Piles Provide Cost-Effective Deep Foundation Support To Control Settlements On An Uncontrolled Fill Site

Project Description:

Expansion of the Southgate Apartment complex included the construction of a new single-story, wood-framed, community center building. Building foundation support featured pile-supported grade beams and a structural slab.

Geotechnical Conditions:

Subsurface conditions consisted of 16 to 19 feet of miscellaneous sand fill containing debris including ash, cinders, glass, porcelain, organics, brick and PVC fragments. One boring encountered 2 feet of peat below the fill. The fill/peat was underlain by loose to medium dense sand extending to 43 feet below grade followed by interbedded silt and sand then very soft to soft clay to a depth of 90 feet where glacial till was encountered. Groundwater levels ranged from 7 to 12 feet below grade during drilling.

Project Challenges:

Providing cost-effective deep foundation support to control settlements on the uncontrolled fill site.

Advantages

- Rapid installations

- Capacity to match the 16-inch diameter augercast piles

- Reduced downdrag loads with smaller diameters

- Low vibration system

Design and Construction Solution:

The foundation plans specified the use of a 16-inch diameter augercast pile extending 38 feet below foundations. The augercast piles were designed with working capacities of 39 kips after subtracting potential downdrag loads components attributed to long-term settlement of the uncontrolled fill.

DuroTerra’s installation partner, Helical Drilling, proposed Ductile Iron Piles as a cost-saving alternative to the augercast piles. The Ductile Iron Pile solution featured a Series 118/6.0 pile (118 mm diameter with 6 mm wall thickness) installed with an oversized cap to construct a 220 mm (8.7 inch) diameter friction pile. During installation, sand cement grout was pumped to fill the annular space created by the oversized cap and develop a friction bond zone in the sand and silt layers. The design required the piles to penetrate the fill and organic soils and then develop frictional capacity through bonding in the underlying sand and interbedded silt and sand layers. Minimum bond lengths of 15 feet were required to achieve a maximum working load of 63 kips. The working loads were based on a 1:1 replacement of the augercast piles as well as consideration of the downdrag load on the piles, which was significantly reduced because of the smaller pile diameter compared with the large augercast piles.

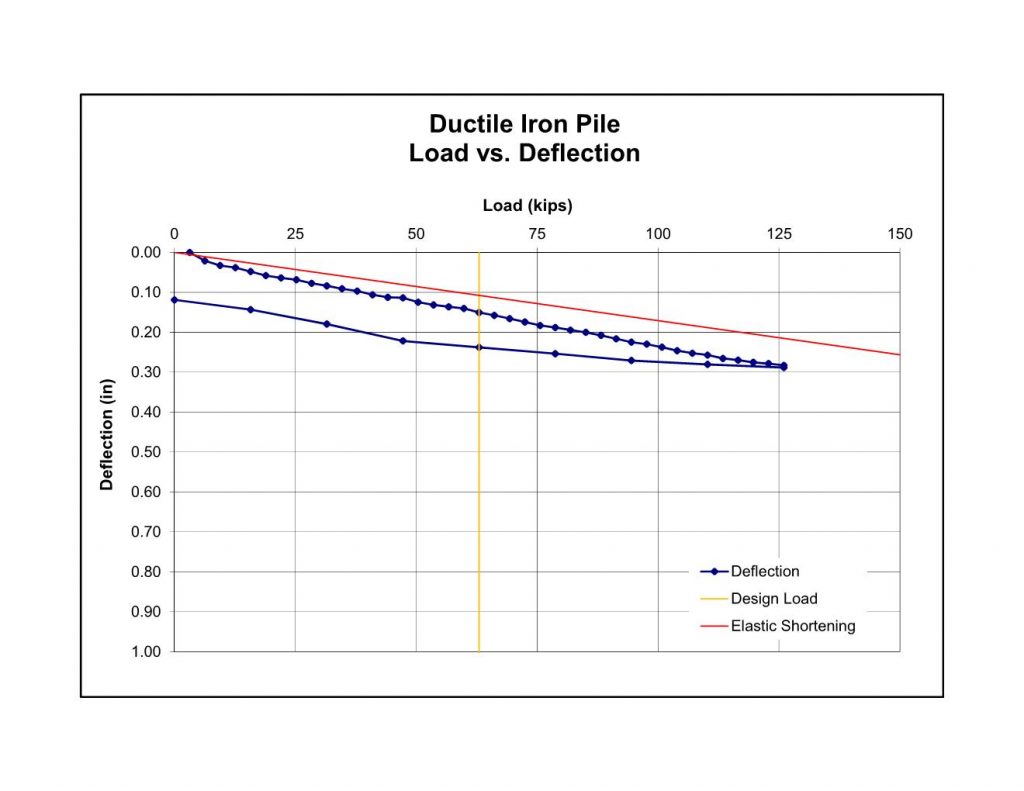

Compression load testing was performed on a 40-ft long, non-production pile to 200% of the design load (126 kips). Results showed about 0.15 inches of movement at the 100% design load (63 kips) and about 0.3 inches at the 200% design load (126 kips). Permanent deformation of 0.12 inches was recorded.

Following load testing, a total of 68 piles were installed on the project with lengths of 40 feet in only 3 days.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: C.T. Male Associates

Structural Engineer: C.T. Male Associates

General Contractor: Essex Builders Corp.