Ductile Iron Piles provided a low vibration deep foundation solution to support the new foundations while working on the constrained site with overhead clearance limitations.

Project Description:

Renovations to the existing Conte Forum basketball arena feature a new 35,700 square foot practice facility for the Boston College basketball programs. The new Hoag Basketball Pavilion will include a strength and conditioning center, sports medicine center, nutrition center, player locker rooms and a renovated 10,700 square foot practice gym. Construction required substantial demolition of the existing northwest corner of Conte Forum followed by construction of the new facility. While some existing foundations could be reused, multiple new foundation locations were required in areas immediately adjacent to the former entrance. Foundation loads were up to 600 kips.

Geotechnical Conditions:

Soil conditions consisted of 7 to 17 feet of uncontrolled fill underlain by 10 to 28 feet of medium dense to dense glacial till (sand and gravel). Bedrock was encountered beneath the glacial till at depths ranging from 17 to 45 feet below ground surface. Groundwater was encountered at depths of 5 to 9 feet below grade.

Project Challenges:

Provide low vibration deep foundation solution to support the new foundations while working on the constrained site with overhead clearance limitations.

Advantages

- Low vibrations

- Rapid installation compared with micropiles

- Cost-savings compared with micropiles

- Clean installation with no spoils

- Demonstrated capacity through load testing

- Ability to work on constrained sites

Design and Construction Solution

The foundation work required a solution that could be installed on a congested site with low vibration and with limited overhead clearance. The plans specified either drilled micropiles or low vibration driven Ductile Iron Piles. Pressure-injected footings (PIFs) were also considered during the bidding phase. The design was based on providing an allowable 75-ton capacity (compression) pile at 38 locations. Ductile Iron Piles were selected for the project based on cost savings, the rapid installation schedule, low vibration, clean installations, and the ability to work in limited overhead conditions if required.

Phoenix Foundation Company, Inc. (Phoenix) provided bids for both the micropiles as well as the Ductile Iron Piles for the project. Phoenix was selected for the design/build Ductile Iron Pile scope of work. Working closely with DuroTerra, Phoenix developed a solution consisting of Series 170/9.0 Ductile Iron Piles installed with a heavy-duty drive shoe to penetrate through the uncontrolled fill and into the glacial till to terminate on very dense glacial till or the underlying rock. Installation was planned with a Tramac V1800 hammer mounted on a CAT 335 excavator.

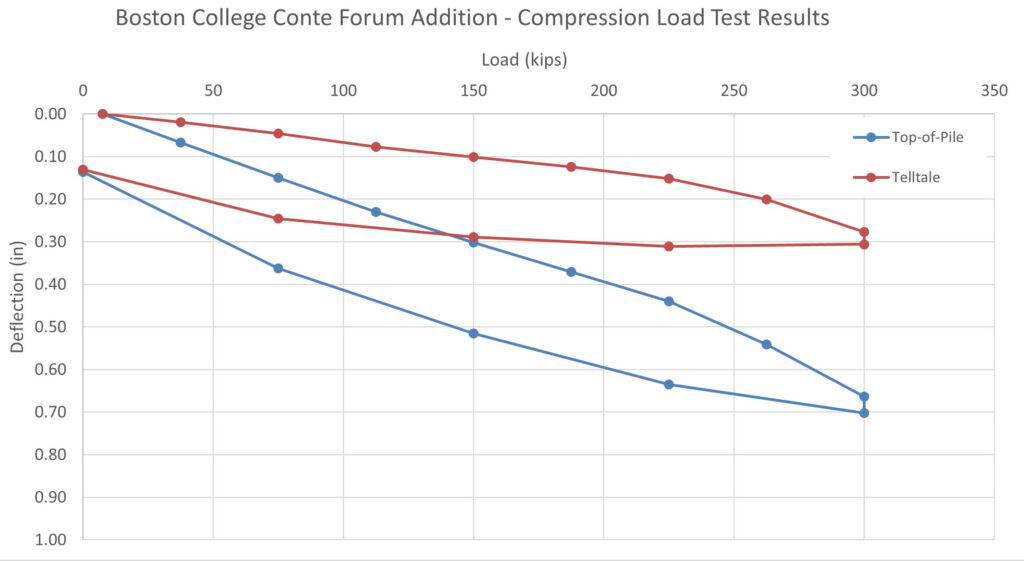

A pre-production load test program was performed by Phoenix to verify the design. The Series 170/9.0 test pile was installed to a depth of 30.3 feet where it achieved a set of 1-inch or less of movement in 50 seconds. Three (3) Geokon strain gauges and a telltale were installed in the test pile to evaluate load dissipation within the pile and confirm sufficient load reached the top of the bearing layer during the test in accordance with state buildingcode requirements. Four exterior grouted Ductile Iron Pile reaction piles were installed with 270 mm (10.6 inch) diameter grout shoes to create 10.6-inch diameter grouted displacement piles. The reaction piles were driven to depths of 28 to 30 feet and a No. 9 threadbar was wet-set into the pile to resist the tension loads during the test.

The pile was loaded up to 200% of the design load (150 tons) where a deflection of 0.70 inches was recorded after completing the creep hold period. The test was then fully unloaded with only 0.14 inches of net (permanent) deflection remaining. The strain gauge data indicated that more than 100% of the design load was transferred to the bottom of the pile during the test. The results of the load test confirmed the design would meet the performance requirements.

Despite numerous challenges and delays associated with unknown and abandoned utility clearing, Phoenix’s crew safely installed the 38 Ductile Iron Piles. The low vibration installation allowed for work immediately adjacent to the existing building. Even though Phoenix planned for installations in clearances as low as 15 feet, the demolition activity resulted in sufficient access to install full sticks at all pile locations. The modular nature of the system enabled the crew to easily mobilize into and work in the constrained work area. Further, the clean installation was a substantial benefit compared with the spoils that would be associated with a comparable micropile system.

Project Team Members

DIP Design/Build Partner: Phoenix Foundation Company, Inc.

Geotechnical Engineer: McPhail Associates, LLC

Construction Manager: Suffolk

Structural Engineer: LeMessurier