Ductile Iron Piles provided a deep foundation solution to avoid the need for dewatering and difficulties with footing construction.

Project Description:

The new theater building at Riverside High School in Decaturville, Tennessee is a one-story building covering an area of 17,750 square feet. Column loads for the new building range from 50 to 60 kips, with wall loads ranging from 6 to 7 kips per linear foot due to 100-ft clear spans.

Geotechnical Conditions:

Subsurface conditions encountered at the site consist of a mixture of sandy gravelly clay, silty sand, sandy gravel and sandy silt with N-values ranging from 5 to 30 bpf. The soils extended to depths ranging from 15 to 19 feet and are underlain by hard, bedded limestone. Groundwater was encountered as shallow as 2 to 3 feet, due to nearby creeks that drain towards Beech River and downhill drainage from the existing campus hardscapes.

Project Challenges:

Due to the large 100-ft clear spans and associated heavy wall loads, conventional spread footings would have to be wider and deeper than normal. This was a constructability concern for the geotechnical engineer due to the high groundwater level. To avoid the need for dewatering and difficulties with footing construction, the design team opted to design for a deep foundation system consisting of Ductile Iron Piles (DIPs.)

Advantages

- Adaptable to variable bedrock elevations

- Simple, low-vibration installation

- Small diameter, high-capacity load resistance

- Rapid turn-key operation

Design and Construction Solution

The Ductile Iron Piles were designed for support of the column and wall loads at spacings ranging from 2 to 11.5 feet on center to accommodate the varying loading conditions. The resulting loading demands required a pile system that could provide capacities up to 100 kips in compression and 7 kips in lateral.

Peterson Contractors, Inc. (PCI) was the selected geotechnical contractor for the work and chose to use non-grouted (exterior) Series 170/9.0 DIPs (170 mm diameter with wall thicknesses of 9.0 mm) for the project. The DIPs were installed using the dry method to achieve “set” of 1” penetration in 50 seconds on the underlying limestone layer. Pile lengths ranged from 14 to 20 feet with an average length of 17 feet. Using an ABI fixed-mast rig equipped with a CAT H140 hammer, PCI installed nearly 200 DIPs in less than one week.

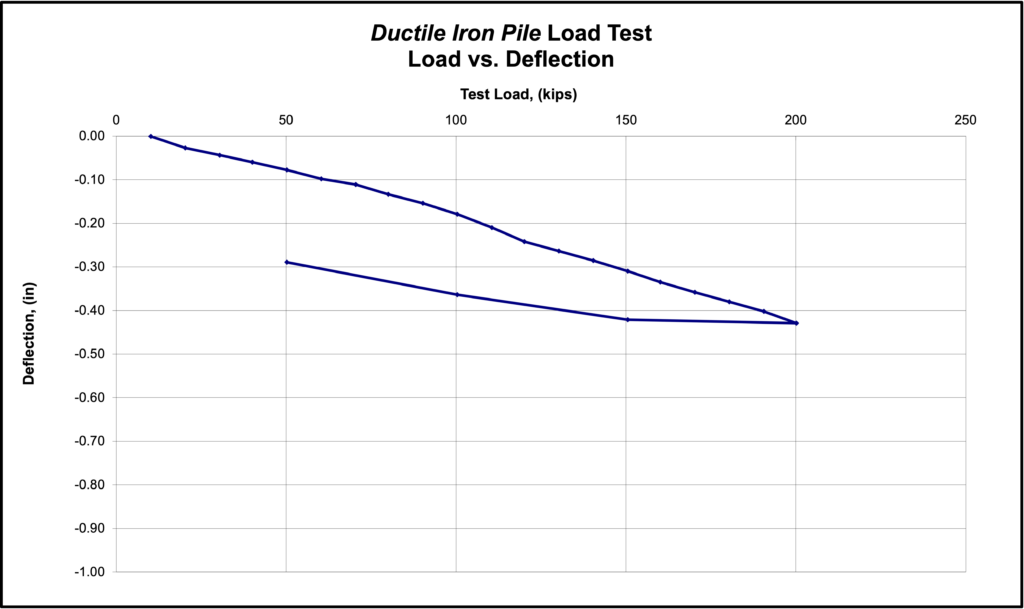

Load testing was performed to 200% of the design load and revealed less than 0.2” of deflection at 100% of the design load and less than 0.5” at 200%. The Ductile Iron Pile system provided exceptional capacity and was installed quickly; unaffected by the high groundwater at the site.

Project Team Members

DIP Installation Partner: Peterson Contractors, Inc.

Geotechnical Engineer: Construction Materials Laboratory, Inc.

General Contractor: Barger Construction

Structural Engineer: TLM Associates