Micropiles Made Simple

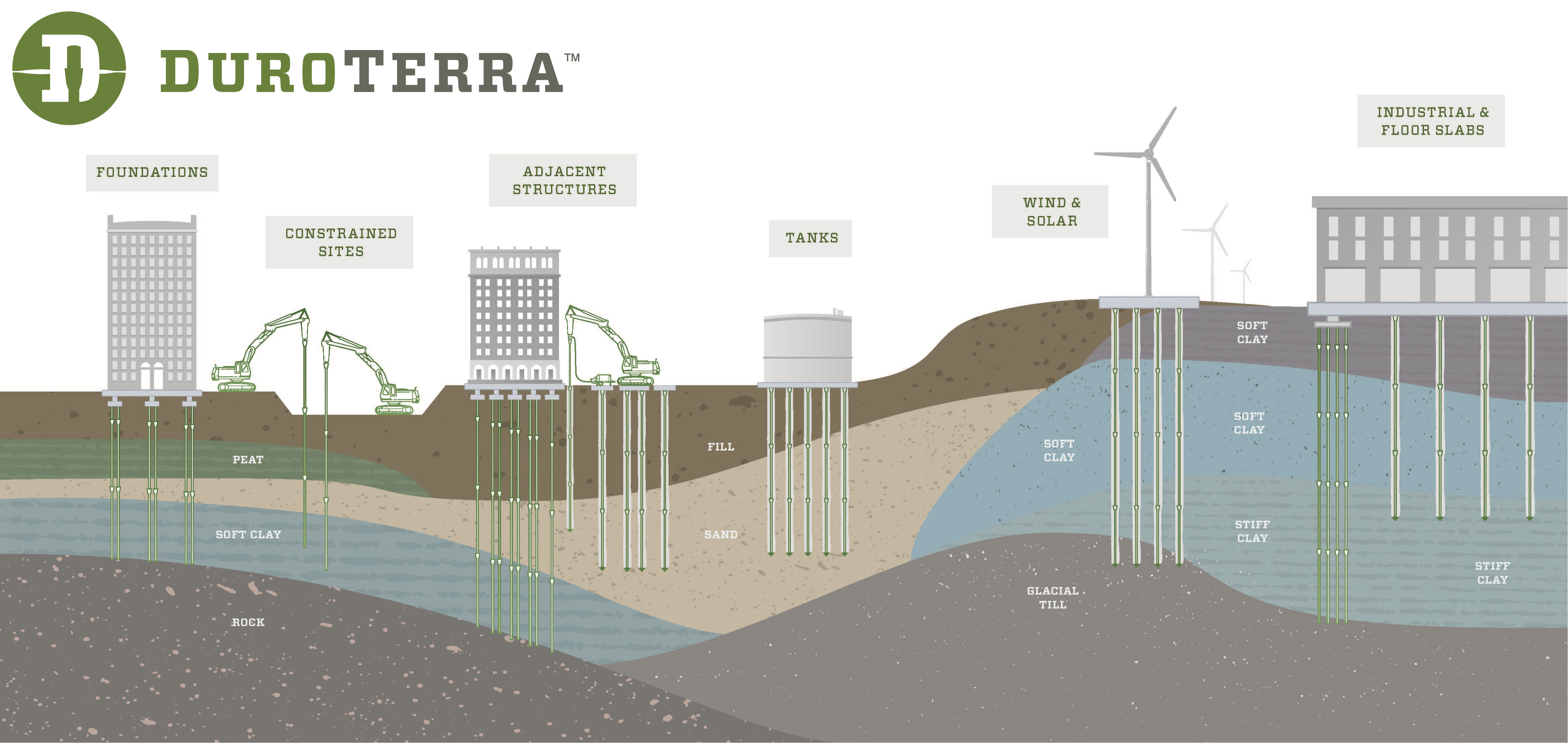

Micropiles fill a niche in geotechnical construction to address sites with challenges including vibration concerns, overhead clearance restrictions and heavily-obstructed conditions. But you often hear words like expensive, slow, messy, complicated, dangerous associated with micropile installations.

Did you know that Ductile Iron Piles (DIPs) are being used more and more by project teams to provide a faster, simpler and less costly alternative to drilled micropiles? The low vibration driven Ductile Iron Pile system features the following advantages:

- Rapid Installation – Installation rates that are typically at least 2 to 3 times faster than micropiles and can exceed 1,000+ ft/day.

- Lower Price – Cost savings on many projects in the range of 25 to 50% over traditional drilled micropiles.

- Low Vibrations – Hammers used for DIP installation generate high frequency percussion energy with vibrations typically less than 1 inch/second to allow installations adjacent to or inside of existing structures.

- Low Overhead Clearance – Excavator-mounted hammer and modular pile set-up can be used in as little as 18 feet of overhead clearance.

- Safe, Clean and Easy – installations are easy, clean and safe with limited moving mechanical parts and controlled grouting operations.

- Minimal Environmental Impacts – Besides being a sustainable foundation system made from 100% recycled materials, the displacement installations eliminate expensive or elaborate spoils management systems for environmentally impacted sites.

Thinking micropiles? Think FAST. SIMPLE. SAFE.® – Ductile Iron Piles. Interested in learning more? Check out the following recent projects where DIPs were used as an alternate to micropiles. If you have additional questions or would like to evaluate feasibility for your micropile project – contact us here

PROJECT EXPERIENCE – ETHAN ALLEN HIGHWAY

Ductile Iron Pile installations around existing structural steel framing

Renovation of a multi-story commercial/industrial building into luxury self-storage facilities required a deep foundation system to transfer building loads below urban fill and organics that varied in depth and extended up to 56 feet. The renovation work required new foundations be constructed in both open areas and tight site conditions where both access and overhead clearance were restricted. Originally designed for a combination of helical piles and micropiles, a value-added alternative using Ductile Iron Piles was selected to replace the helical piles and many of the micropiles. While foundations in areas with less than 10 ft of overhead clearance remained supported by micropiles, the remainder of the project was supported on Series 118/7.5 Ductile Iron Piles with design capacities of 75 kips. Over 400 Ductile Iron Piles were installed across the site with lengths of 70 feet. Achieving production rates of over 1,800 LF/day, the Ductile Iron Pile scope was completed in only 36 days of driving. The alternative approach provided an estimated cost and time savings of over $1M and 2 months. To learn more about the project, check out the full project summary.

PROJECT EXPERIENCE – DALLAS MAVERICKS PRACTICE FACILITY

Ductile Iron Piles were installed within 28 ft overhead clearance as part of the building renovation

Renovation of an existing 30,000 square foot commercial building was required to accommodate the new Dallas Mavericks basketball practice facility. The new facility included two full-sized courts, locker rooms, a weight room and office space. New foundations were required in numerous locations. With overhead clearances restricted to 28 feet, a low vibration driven Ductile Iron Pile solution was selected by Keller, the geotechnical contractor on the project. The DIPs were selected over helical piles and micropiles based on speed of installation and ability to drive through undocumented fill. Piles were installed to penetrate up to 26 feet of debris fill followed by very soft to stiff clay and sand extending to rock at 60 to 65 feet. To learn more about the project, check out the full project summary.