Ductile Iron Piles Provide Foundation Support To Match Original Foundation System In Port Richey, Florida

Project Description:

The mixed-use commercial and residential development in downtown New Port Richey included two buildings. The project was started in the mid-2000’s but ground to a halt during the economic downturn with only the shell of the first building and portions of the second building foundations constructed. After a decade, the project restarted. New foundation work was needed to support portions of original design that had never been installed and localized areas of redesign. Foundation loads ranged from 80 to 320 kips for pile caps and about 4 kips/foot for walls.

Geotechnical Conditions:

Soil conditions consisted of very loose to dense sand with isolated stiff clay layers overlying limestone bedrock with varying degrees of weathering. SPT N-values in the limestone ranged from 2 bpf to 50/0”. Competent rock was encountered at depths ranging from less than 20 feet to greater than 45 feet.

Project Challenges:

Provide foundation support to match the original foundation system and easily adapt to highly-variable rock depths.

Advantages

- Easily adjust to varying rock depths

- Re-use of cut sections minimizes waste

- Rapid installation

- Low vibrations

Design and Construction Solution:

The original foundation design for the project specified the use of Series 118/7.5 Ductile Iron Piles installed to lengths of 48 feet (3 sticks). The piles were designed with a capacity of 40 tons (compression). The new scope of work consisted of a total of 96 piles that were required to complete the foundation system. All piles were driven through the soils and weak rock to achieve “set” at a driving rate of less than 1 inch of movement in 50 seconds or more. Pile lengths varied considerably based on the weathering of the limestone. The use of the bell-spigot connection allowed the system to easily adapt to variable lengths and have only minimal waste since cut-off pieces were used as starter pile sections.

The original foundation design for the project specified the use of Series 118/7.5 Ductile Iron Piles installed to lengths of 48 feet (3 sticks). The piles were designed with a capacity of 40 tons (compression). The new scope of work consisted of a total of 96 piles that were required to complete the foundation system. All piles were driven through the soils and weak rock to achieve “set” at a driving rate of less than 1 inch of movement in 50 seconds or more. Pile lengths varied considerably based on the weathering of the limestone. The use of the bell-spigot connection allowed the system to easily adapt to variable lengths and have only minimal waste since cut-off pieces were used as starter pile sections.

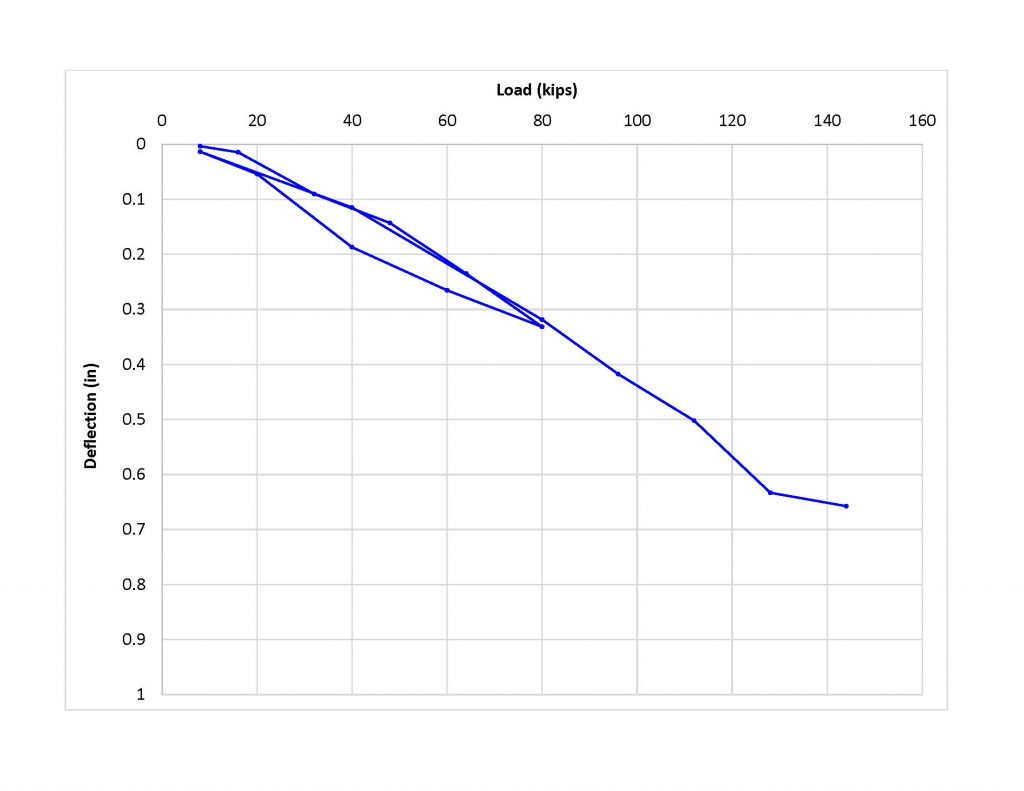

A full-scale compression load test was performed on a non-production pile to verify capacity. The compression load test showed only 0.32 inches of movement at 40 tons (100%). At 72 tons (180%), the response was trending linearly with a deflection of 0.66 inches. However, lateral movement due to eccentric loading of the pile was noted as the test was loaded to 200%, creating an unsafe loading condition, and the test was discontinued. The design team concluded that the results of the test were sufficient to confirm acceptable performance and met the design requirement.

Project Team Members

DIP Design/Build Partner: Foundation Services of Central Florida, Inc.

Geotechnical Engineer: SDII Global Corporation

General Contractor: Onicx Construction, LLC

Structural Engineers: Universal Engineering/ SDII Global