Ductile Iron Piles provided a low vibration foundation support solution installed adjacent to the existing sewer.

Project Description:

The project consisted of a new 50-unit, 4-story residential apartment building in downtown Des Moines. An existing 72-inch diameter ”Bird’s Run” historical brick sewer passed transversely through the center of the site beneath the proposed building footprint.

Geotechnical Conditions:

Soil conditions consisted of urban fill (clay and sand with cinders) ranging in depths between 3 and 27 feet followed by alluvial sand and clay and then shale bedrock. Rock levels varied across the site from 6 to more than 45 feet.

Project Challenges:

Provide a low vibration foundation support solution installed adjacent to the existing sewer to transfer foundation loads passed the sewer to rock below while also maintaining compatibility with the ground improvement foundation support used for the rest of the project.

Advantages

- Low displacement and low vibrations

- Develop capacity in end-bearing

- Compatibility with ground improvement system

- Ability to adjust to variable rock depths

Design and Construction Solution

The geotechnical engineer recommended ground improvement for foundation support in areas away from the existing sewer. However, they recognized that ground improvement installation would generate unacceptable vibrations and soil displacement in the area of the sewer and also result in load transfer to the sewer. The design team required an alternative support solution for the foundations adjacent to the brick sewer to avoid imparting construction vibrations or lateral stress on the sewer and transfer future building loads below the sewer. The team designed a structural slab supported by Ductile Iron Piles to span over the brick sewer and transfer the building loads to the rock.

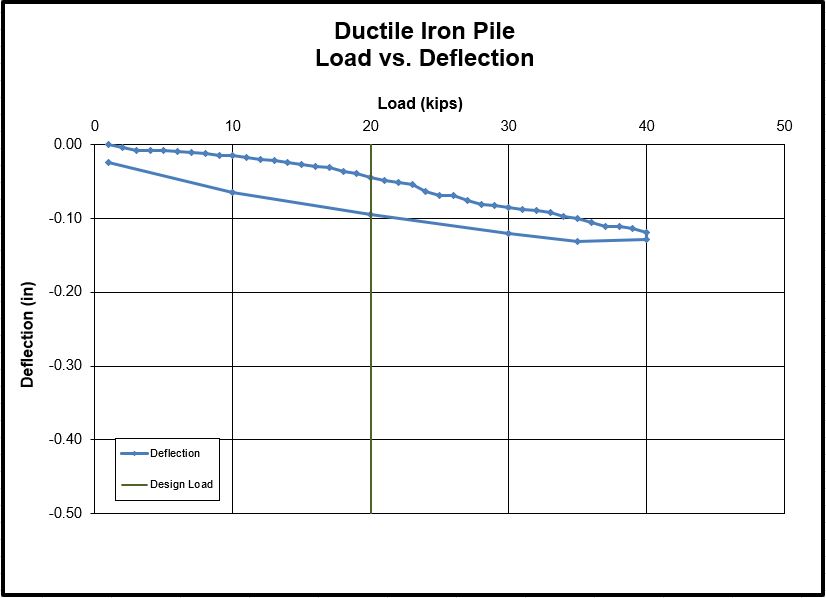

A total of 22 Ductile Iron Piles were required for support of the slab. One row of piles on each side of the sewer were spaced at 6 ft on-center. Design loads of only 10 tons were required. A Series 118/7.5 (118 mm outer diameter and 7.5 mm wall thickness) Ductile Iron Pile was used. Prior to installation, Foundation Service Corp. performed load testing on a non-production pile. Test results showed only 0.12 inches of movement at 40 kips (200% of the design load). The piles were installed to terminate on rock in only 2 days. The ground improvement design featured a transition zone with closely spaced ground improvment elements to reduce differential settlement between the systems.

Project Team Members

DIP Designer: Ground Improvement Engineering, Inc.

DIP Installer: Foundation Service Corp.

Geotechnical Engineer: Allender Butzke Engineers, Inc.

Structural Engineer: Raker Rhodes Engineering