Back to School 2024

Despite having just promoted the idea of summer vacation in our last DuroTerra Dialogue, the eventual end of summer is now rapidly approaching. And with the end of summer comes a time for students everywhere to dread and parents everywhere to rejoice – BACK TO SCHOOL!

Despite having just promoted the idea of summer vacation in our last DuroTerra Dialogue, the eventual end of summer is now rapidly approaching. And with the end of summer comes a time for students everywhere to dread and parents everywhere to rejoice – BACK TO SCHOOL!

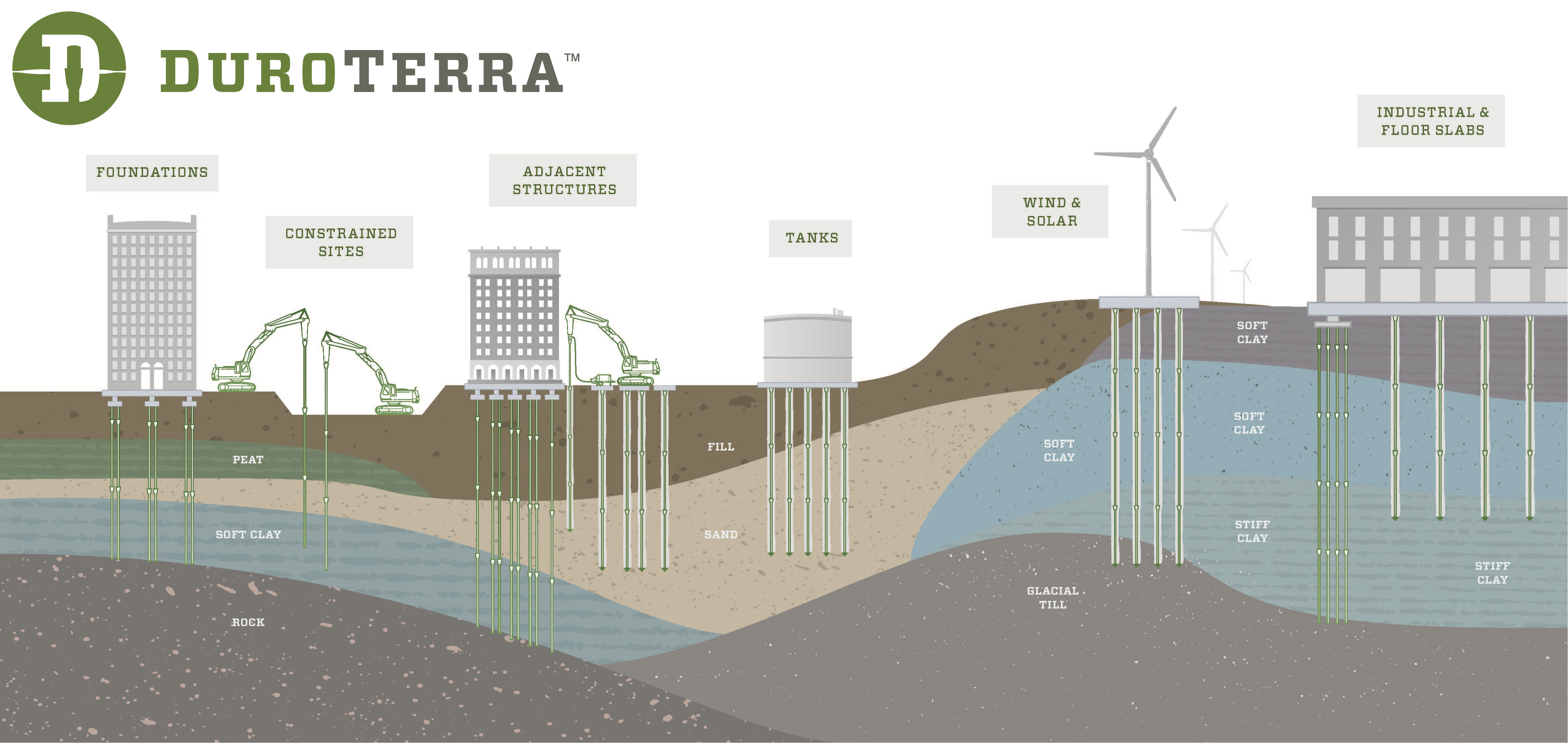

Students, teachers and administrators are not the only ones going back to school. Many geotechnical specialty contractors have been busy working to install Ductile Iron Piles for support of academic projects ranging from elementary schools to institutions of higher education. Ductile Iron Piles are often selected as the foundation solution due to cost and schedule savings particularly on sites with varying rock elevations, tight site access, low overhead working conditions, or building additions with sensitivity to vibrations.

As kids and adults alike head back to the classroom, many will be in buildings where the FAST. SIMPLE. SAFE.® Ductile Iron Pile deep foundation system is supporting them. The following are a couple of academic projects by our installers. Check out our website for many more (duroterra.com/projects/).

MIT EARTH AND ENVIRONMENTAL PAVILION

Renovation work of the existing Cecil and Ida Green Building (Building 54) on the Massachusetts Institute of Technology (MIT) campus included construction of a new gateway Pavilion (Building 55) to serve as the entrance to the renovated home of the Earth, Environmental and Climate Sciences Research and Education building. Construction of the pavilion required support of foundations loaded up to 400 kips. Some of the foundation work required installation immediately adjacent to an existing service tunnel that crossed the site. As an alternative to pressure-injected foundations (PIFs) and ground improvement, Ductile Iron Piles offered a lower vibration solution to work on a tight site on the campus. An exterior grouted displacement DIP using Series 118/9.0 with a 270 mm (10.6”) diameter grout shoe was installed to transfer the 25 ton working loads through the uncontrolled fill, loose sand and organics to develop frictional capacity in the underlying medium dense to very dense sand and the very stiff Boston blue clay crust. After successful performance of a full-scale compression load test to 200% (100 kips) of the design load, the 42 production Ductile Iron Piles were installed in only 4 days by Phoenix Foundation Company. For more information, check out the project summary.

MIT EARTH AND ENVIRONMENTAL PAVILION

Cambridge, MA The new Golf Team building at University of Central Missouri contains food services, meeting rooms and lockers for the university’s men’s and women’s golf teams. While the 1,900 square foot building was relatively lightly loaded, the building was planned to be built partially over a landscaped earth dam used to form a water feature on the golf course. The use of shallow foundations was going to require large amounts of earthwork and had the potential for differential settlement. Instead, deep foundations were designed to accommodate the elevation change and minimize earthwork needs on the project, while also controlling settlement issues. The original project scope included 53 production micropiles installed in limestone at 16 to 20 feet below grade to develop a 35 kip working capacity. Ductile Iron Piles were selected as a value engineered solution using a higher capacity (~45 tons) to reduce the pile quantity by 20 piles. Foundation Specialties GeoStructural Construction performed a successful load test and installed a total of 33 production piles using Series 118/7.5 Ductile Iron Piles. All piles were terminated on limestone ranging in depth from 12 to 20 feet below grade. Installation rates with the Epiroc HB2000 hammer mounted on the Hitachi 345 excavator averaged over 800 LF per day. For more information, check out the project summary.

The new Golf Team building at University of Central Missouri contains food services, meeting rooms and lockers for the university’s men’s and women’s golf teams. While the 1,900 square foot building was relatively lightly loaded, the building was planned to be built partially over a landscaped earth dam used to form a water feature on the golf course. The use of shallow foundations was going to require large amounts of earthwork and had the potential for differential settlement. Instead, deep foundations were designed to accommodate the elevation change and minimize earthwork needs on the project, while also controlling settlement issues. The original project scope included 53 production micropiles installed in limestone at 16 to 20 feet below grade to develop a 35 kip working capacity. Ductile Iron Piles were selected as a value engineered solution using a higher capacity (~45 tons) to reduce the pile quantity by 20 piles. Foundation Specialties GeoStructural Construction performed a successful load test and installed a total of 33 production piles using Series 118/7.5 Ductile Iron Piles. All piles were terminated on limestone ranging in depth from 12 to 20 feet below grade. Installation rates with the Epiroc HB2000 hammer mounted on the Hitachi 345 excavator averaged over 800 LF per day. For more information, check out the project summary.