Friction Ductile Iron Piles

Introduction:

Johnson & Wales University launched construction of a new $40M, 3-story academic building. The 71,000 square foot facility will house classrooms, offices and labs. The project footprint is bordered on two sides by immediately adjacent Johnson & Wales buildings, requiring a solution to support foundations without adverse impacts to the existing buildings. Column loads in these locations of the building ranged from 150 to 600 kips with up to 45 kips of uplift (tension) at select locations.

Geotechnical Conditions:

The subsurface conditions encountered in the explorations generally consist of sand fill with various amounts of silt and demolition debris (brick, concrete, asphalt, wood) extending to depths of up to 11 feet. The urban fill was underlain by medium dense to dense sand and silt glacial outwash deposits and very dense glacial till. Groundwater was encountered at about 23 feet below ground surface.

Project Challenge:

Construction of a heavily-loaded building addition on uncontrolled fill immediately adjacent to existing structures.

Advantages

- Rapid installation

- High capacity with bonded friction DIP

- Verifiable performance with load testing

Design and Construction Solution:

The owner and geotechnical engineer had successfully used Ductile Iron Piles on a previous project on the Johnson & Wales campus to provide a cost-effective alternate to traditional solutions like drilled micropiles. The constrained working conditions for the new Academic Building combined with the high loads was an ideal fit for the Ductile Iron Pile option.

The project design specified the use of a 37.5 ton Ductile Iron Pile consisting of a 118/7.5 series pile (118 mm diameter pile with a 7.5 mm wall thickness). On a previous project, Ductile Iron Piles extended through the dense glacial till to end-bear on rock. A more cost-effective solution was designed for the new building using an oversized 220 mm diameter conical grout cap to develop capacity with a friction bond zone in the sand underlying the fill. Pile lengths of 25 feet were designed to resist the applied working loads of 75 kips. High-strength, center reinforcing bars were installed in isolated piles to provide resistance to the tension loads.

Helical Drilling rapidly installed the Ductile Iron Piles to extend through the fill and terminate in the sand. Piles maintained a minimum bond length of 16 feet in the sand. A total of 66 piles were installed in 3 working days. Vibration levels were so minimal that monitoring was discontinued.

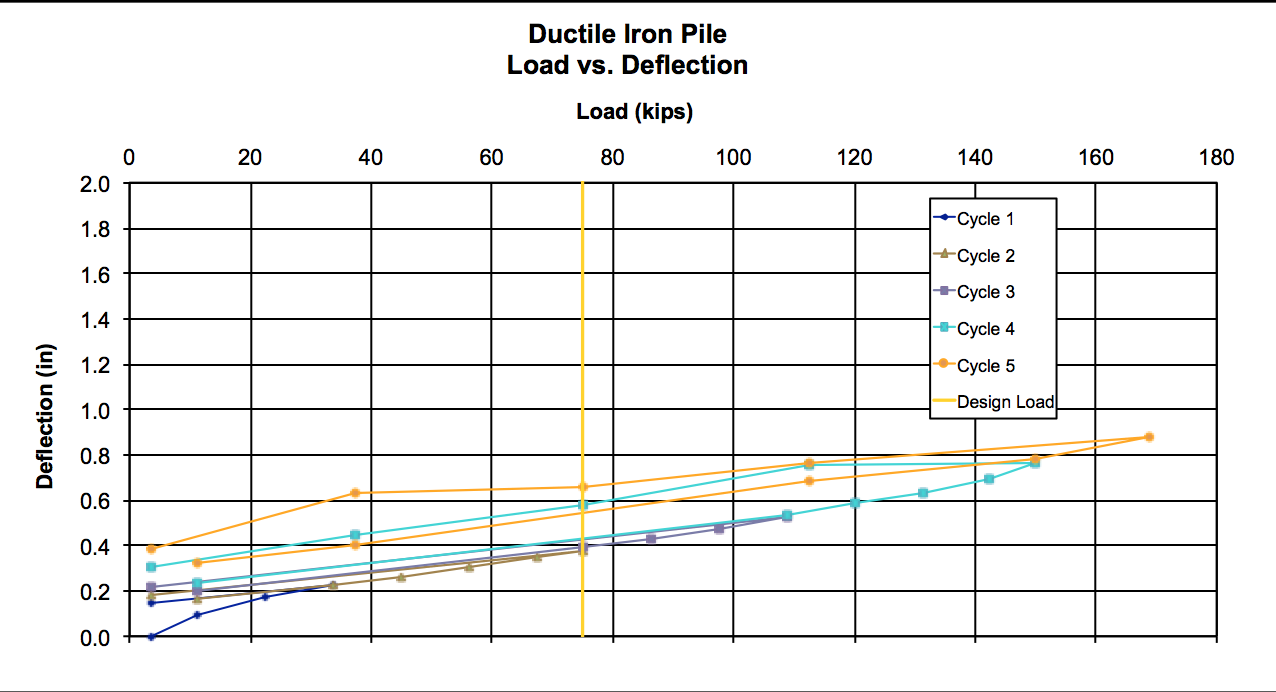

A full-scale tension load test was performed to confirm the design capacity and performance with the 16-foot bond length. At the design load of 75 kips (Cycle 2), upward deflection of the friction DIP was limited to 0.38 inches. The test was performed up to 200% of the design load (150 kips) where the total deflection was 0.76 inches (Cycle 4). Following the final unloading, the test was reloaded to evaluate performance up to 225% (Cycle 5) where movement was still limited to only 0.88 inches and maintained load resistance. Net deflection after unloading the pile was limited to under 0.4 inches.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: GZA GeoEnvironmental

Construction Manager: Manafort Brothers, Inc.

Construction Manager: Dimeo Construction Company

Structural Engineer: Odeh Engineers, Inc.