INTRODUCTION:

Revitalization of a site three blocks from historic Fenway Park involved construction of a new 5-story apartment building located immediately surrounded by existing 3-story residences.

Geotechnical Conditions:

Soil conditions consisted of up to 9 feet of loose to medium dense “urban” sand fill underlain by soft peat and organic clay/silt to 28 feet. The fill and organics were underlain by very soft to medium stiff clay extending to a depth of 175 feet where bedrock was encountered.

Project Challenge:

- Economically supporting heavy building loads through deep, soft soils with minimal vibration in a congested residential neighborhood

Advantages

- Significant cost savings over traditional H-piles and drilled micropiles

- Limited vibrations in sensitive residential area

- Rapid DIP installation – more than twice as fast as alternatives

- Easy access to the urban site

- Eliminated time and costs associated with pile splicing

- Limited laydown area on congested site due to modulus pile system

Design and Construction Solution:

With loads approaching 600 kips, deep foundation support was required at the fill/soft soil site. The project team initially considered driven steel H-piles with 100 ton capacities. High vibrations coupled with the challenges of transporting long pile sections and the added cost/time for pile splicing led the design team towards a more practical solution for the urban site. Ductile Iron Piles were selected as a more cost-effective and faster alternative to the H-piles and traditional drilled micropiles. The Ductile Iron Pile system provided a 2:1 replacement of the H-piles with a working capacity of 50 tons.

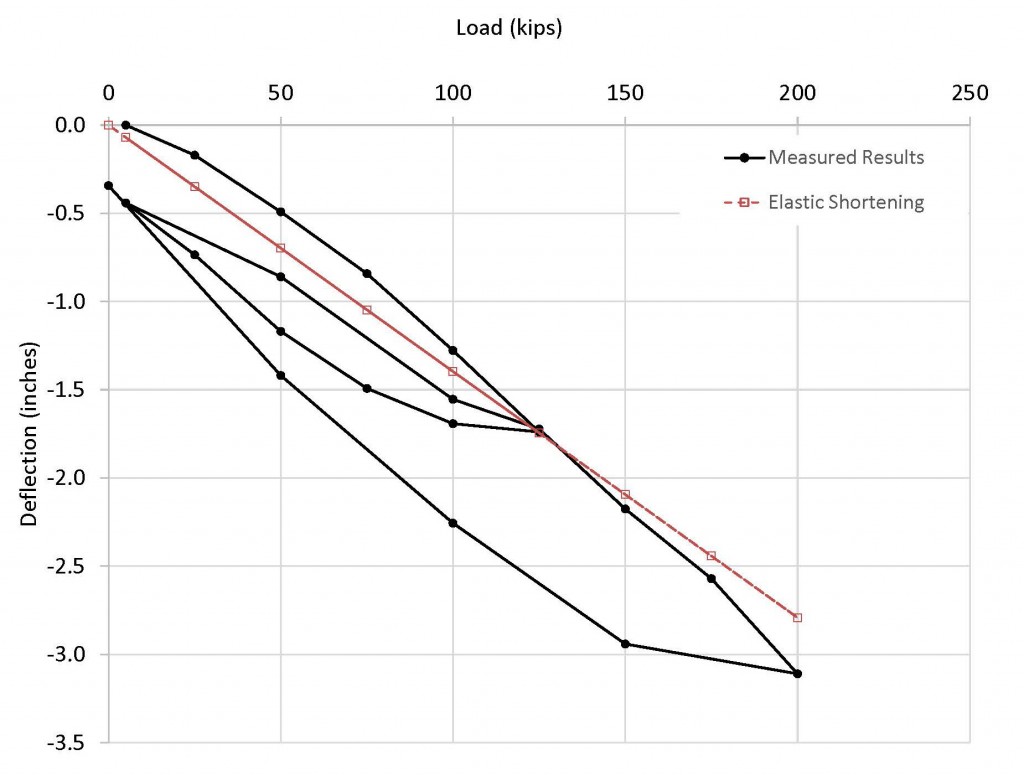

Prior to the start of production operations, Helical Drilling, Inc. installed the 50 ton test pile (Series 118/7.5) to terminate on rock at a depth of 175 feet. The test pile was loaded using a gravity reaction load test setup because of the costs associated with deep rock anchors for tension resistance. Load testing of the end-bearing Ductile Iron Piles showed a deflection of 1.25 inches at the design load (100%) of 50 tons. The load test was performed to 200% of the design load (100 tons). The response was nearly perfectly elastic with a deflection at the maximum test load approaching 3 inches. The deflection of the 175-ft long test pile met expectations for compression of a long micropile. The results met the project teams expectations while also delivering foundation economy.

Production pile installation was performed at rates of 1,000 feet per day or more. A total of 87 piles were installed in just over 2 weeks. Vibration monitoring performed during installation recorded peak particle velocities of only 0.3 inches/second on the ground 2 feet away from installations. The vibrations were reduced to 0.15 inches/second a distance of 4 feet away. Measurements on the existing building foundations were less than 0.15 inches/second while installations were within 2 feet from the building.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: Briggs Engineering

General Contractor: Boston Design Construction

Structural Engineer: DM Berg Consultants, P.C.

Architect: Nunes Trabucco Architects