Are you torqued out with Helical piles?

Helical piles are a good tool for underpinning existing structures and supporting new boardwalks and lightly loaded buildings. Like any piling system, there can be limitations that impact the overall benefit. We often hear these common concerns from design professionals and contractors on projects considering helical piles.

- What if I don’t achieve the torque requirements?

- What about cost overruns when I have to extend deeper to generate the required capacity?

- I need greater pile capacity to optimize my foundations but I’m not sure if I can get there with helical piles in my soil conditions.

- Will the helical piles “torque out” before getting through an undocumented fill, or worse, “spin out” in soft soils over a hard layer leaving me with questions about capacity?

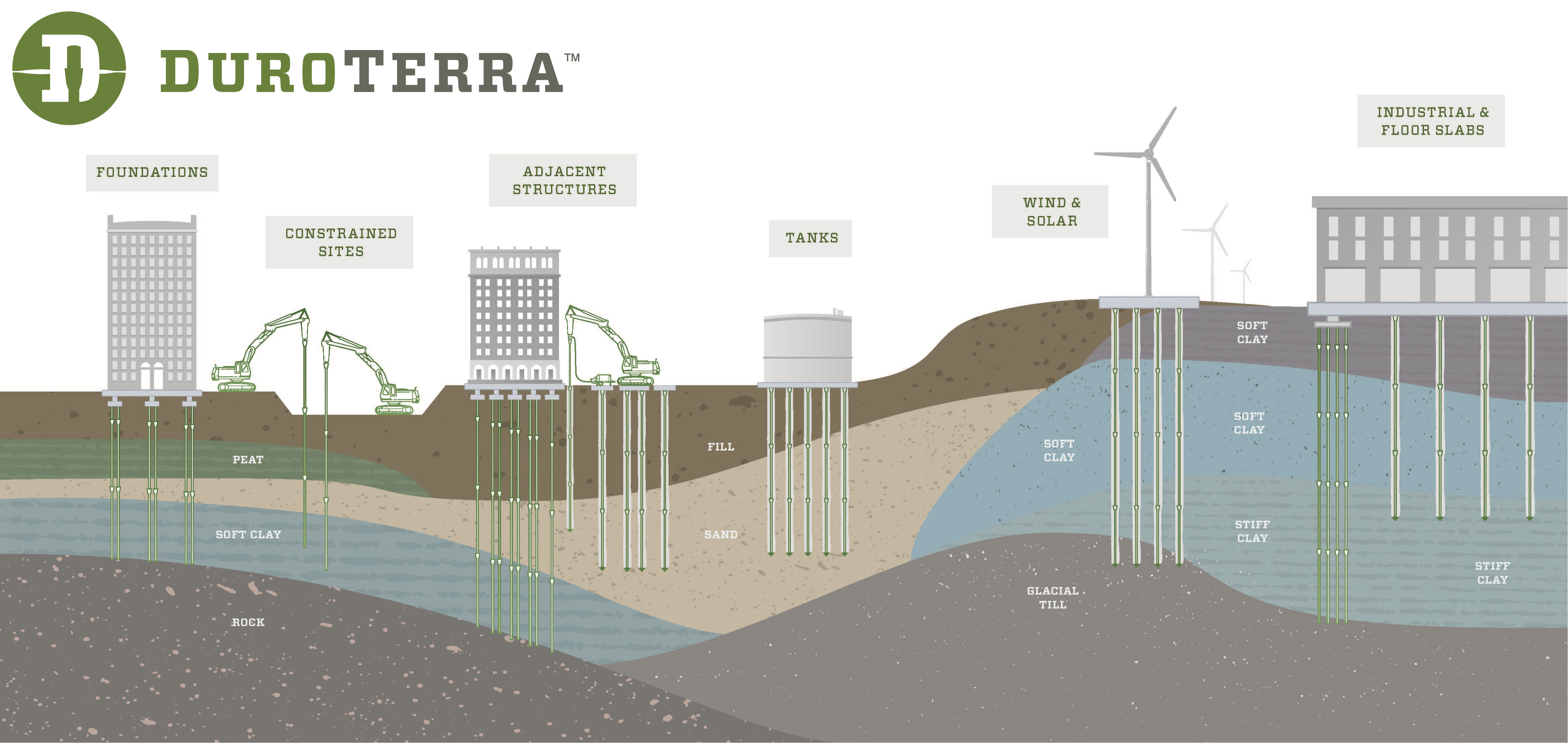

Ductile Iron Piles have become a go-to alternative for helical pile projects to provide a reliable, higher-capacity alternative for new construction, building additions and interior renovations. The modular, low-vibration Ductile Iron Pile system is installed using an excavator-mounted, medium-sized percussion hammer to drive the pile using high-frequency percussive energy. This method produces minimal vibrations, allowing the system to effectively work immediately adjacent to or inside existing buildings. The modular piles and medium-sized equipment allow the system to be easily used on tight sites where limited access solutions (like helical piles) might be required. In addition, TRM’s Plug and Drive connection system results in rapid installations with production rates of 400 to more than 1,200 linear feet per crew day.

Ductile Iron Piles offer compression capacities of 25 to more than 100 tons by either end-bearing on competent soil/rock or by creating a grouted friction bond zone like a micropile. The greater capacity often results in fewer piles and a more cost-effective foundation. This versatility in developing geotechnical resistance provides confidence that you will develop high capacities in a variety of ground conditions and lowers your risk for change orders resulting from unexpected helical pile performance.

Please check out the following projects where Ductile Iron Piles proved to be a superior alternative to helical piles. And if you are considering helical piles on your project, reach out to us for a feasibility assessment to know your options.

PROJECT EXPERIENCE – RHODE ISLAND AIR NATIONAL GUARD – ADAL FUEL CELL BUILDING 8

Renovations and improvements to the Rhode Island Air National Guard 143rd Airlift Wing’s ADAL Fuel Cell Building 8 project in North Kingstown included two separate building additions as well as interior work within the existing building. The single story additions totaled about 2,800 square feet and were connected to the existing building on the northeast and southwest corners. Foundations were designed as a series of interconnected grade beams and pile caps.

Project foundation support was designed for helical piles with a design capacity of 40 kips. During installation of the helical piles, substantially lower torque levels were recorded in the loose sand, resulting in significantly reduced capacities. After consideration of the alternatives, the design team decided to switch to a low vibration, friction Ductile Iron Pile to meet the original pile capacity requirements for foundation support. Series 118/7.5 (118 mm diameter with 7.5 mm wall thickness) piles with a 220 mm oversized conical grout cap were selected for the re-design. The DIP design was based on penetrating the fill and developing friction capacity with a 17-foot bond length in the underlying sand layer, for a total of 35 ft. piles.

Two pre-production compression load tests were performed at the site; one in each building addition area. Each pile moved less than 0.05 inches at the design load of 40 kips (100%) and less than 0.12 inches at 80 kips (200%). Test results confirmed the working capacity. The installation of 73 production piles to depths of 35 feet was achieved in only 3 working days, averaging more than 850 linear feet per day. For more information, check out the project summary.

PROJECT EXPERIENCE – GE WASTEWATER BUILDING

Schedule and responsiveness play an important role in meeting project deadlines – especially when winter is bearing down on your foundation work in Upstate New York. Renovations and improvements to the existing General Electric (GE) facility in Schenectady, New York specified helical piles for foundation support. The project team was concerned about the delay risk associated with problems penetrating the fill and achieving the required capacity in poor soil conditions. An alternative approach using friction Ductile Iron Piles provided a cost-effective solution to easily drive through the fill and develop frictional capacity through grout-to-ground bonding. Design, mobilization, testing, installation and demobilization were all completed within only 2 weeks after project award. A total of 55 production piles were installed to depths of about 50 feet in only 2 working days, well ahead of the winter weather. Successful performance on this project has led to the use of Ductile Iron Piles on multiple other projects on the base. For more information, check out the project summary.