Ductile Iron Pile System Replaces Helical Piles for Foundation Support

Project Description:

Renovations and improvements to the Rhode Island Air National Guard 143rd Airlift Wing’s ADAL Fuel Cell Building 8 project in North Kingstown included two separate building additions as well as interior work within the existing building. The single story additions totaled about 2,800 square feet and were connected to the existing building on the northeast and southwest corners. Foundations were designed as a series of interconnected grade beams and pile caps.

Geotechnical Conditions:

Borings completed at the site encountered between 9 and 15 feet of miscellaneous fill consisting mostly of sand, gravel and trace amounts of silt underlain by very loose to loose fine sand extending up to 38 feet below grade. The sand then increased in density to medium dense to dense and extended to the maximum explored depth of up to 52 feet. Groundwater was encountered at 8 feet below grade.

Project Challenges:

Use a low-vibration, friction pile to develop sufficient capacity in the sand and gravel to replace helical piles for foundation support.

Advantages

- Substantially greater and more reliable capacity than helical piles

- Rapid installation

- Low vibration installation adjacent to existing building

- Superior performance under load testing

Design and Construction Solution:

Project foundation support was designed for helical piles with a design capacity of 40 kips. During installation of the helical piles, substantially lower torque levels were recorded in the loose sand, resulting in significantly reduced capacities. After consideration of the alternatives, the design team selected a low vibration, friction Ductile Iron Pile to meet the original pile capacity requirements for foundation support.

The Ductile Iron Pile system is well-suited for working within limited access areas and produces minimal vibrations during installation. A Series 118/7.5 (118 mm diameter with 7.5 mm wall thickness) pile with a 220 mm oversized conical grout cap was selected for design. The DIP design was based on penetrating the fill and developing friction capacity with a 17-foot bond length in the underlying sand layer.

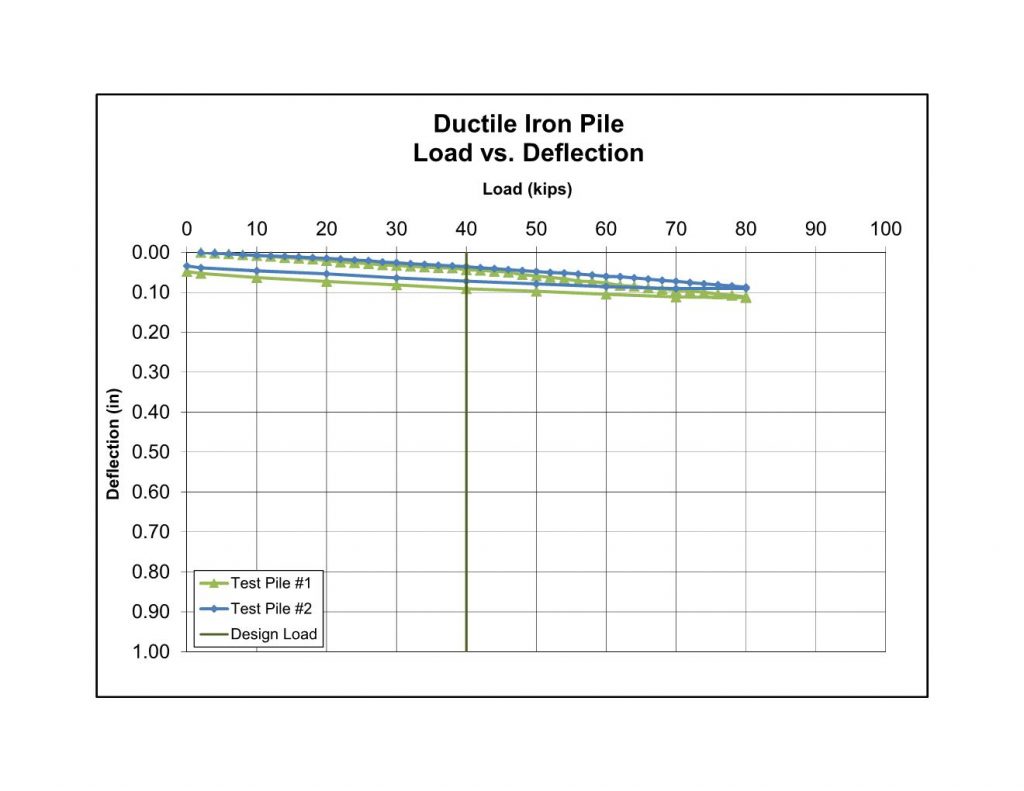

Two pre-production compression load tests were performed at the site; one in each building addition area. Each pile moved less than 0.05 inches at the design load of 40 kips (100%) and less than 0.12 inches at 80 kips (200%). Test results confi rmed the working capacity. The installation of 73 production piles to depths of 35 feet were achieved in only 3 working days, averaging more than 850 linear feet per day.

Project Team Members

DIP Design/Build Partner: Helical Drilling

Geotechnical Engineer: Geisser Engineering Corporation

Structural Engineer: Jacobs Engineering

General Contractor: Cutter Enterprises