Can Ductile Iron Piles be used for infrastructure projects?

Can Ductile Iron Piles be used for infrastructure projects?

We routinely are asked this question by engineers and contractors looking to get the best value for their foundations on infrastructure projects. It’s a timely question now with the renewed focus on the U.S. infrastructure projects making the news as President Biden signed the $1 Trillion infrastructure bill into law earlier this week. The law provides funding for improvements to roads, bridges, water systems, broadband, ports, and power grids among many other projects.

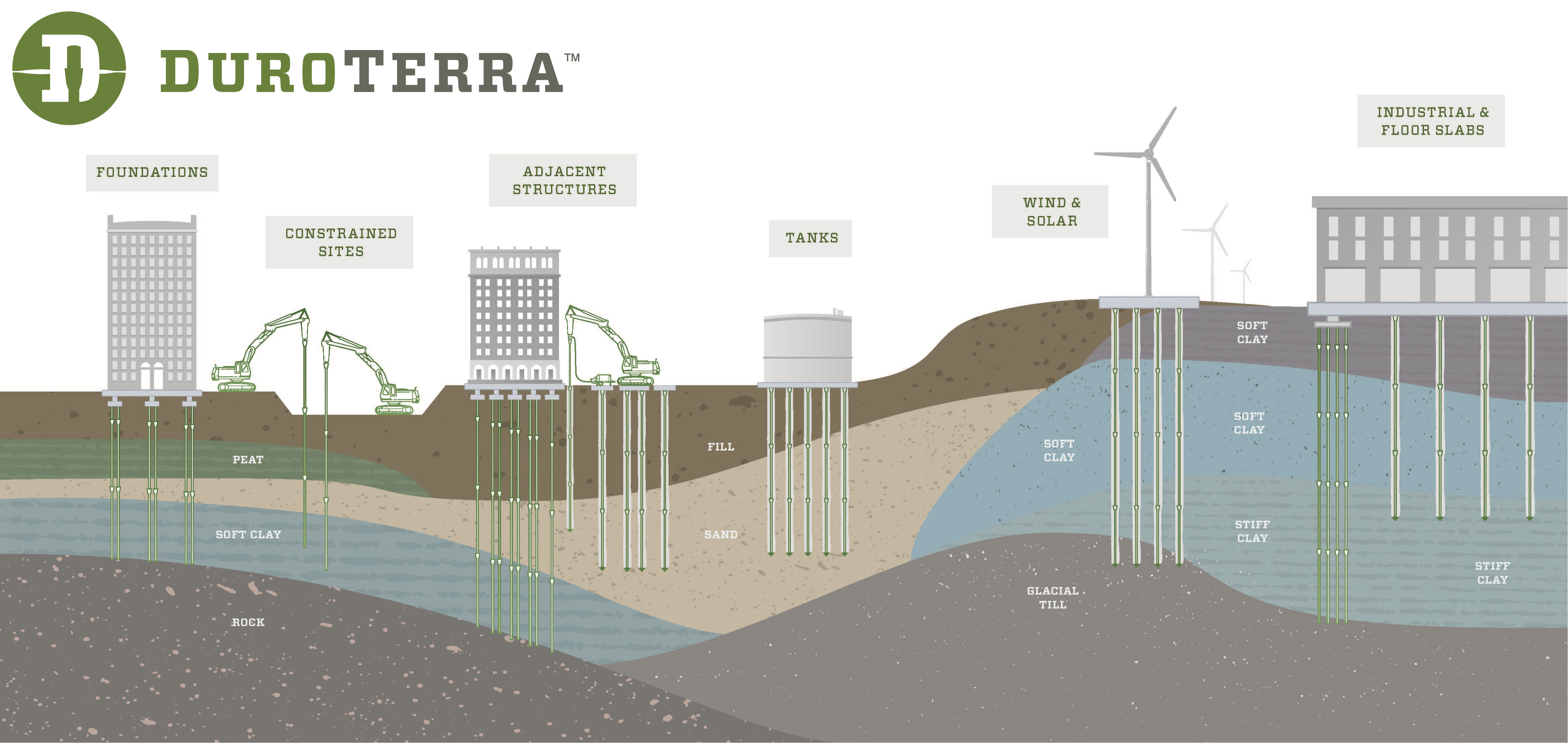

The short answer is that it depends on the funding source. While TRM’s Austrian-manufactured Ductile Iron Piles don’t meet Buy America requirements on applicable federally funded projects, DuroTerra and our network of specialty contractors around the U.S. and Canada have a track record of providing cost-effective solutions for military, state, and municipal projects closer to home where the only requirement is best value. The same benefits delivered by TRM piling on private sector projects often translate to significant advantages on public sector work. Advantages include ease of access working from variable grades for new abutments on a local bridge replacement to rapidly installing foundations for a new pump station upgrade project as you’ll see below. Not to mention working in limited overhead situations, low vibrations, rapid installations and finally – simplicity of mobilization and installation for small projects.

If you are looking for a FAST. SIMPLE. SAFE. foundation solution on your project, don’t hesitate to reach out regardless of the size (as you’ll see below).

Relevant projects

Construction of a new 175-foot long pedestrian bridge as a part of the Cheney Rail Trail required support of two new abutments along the existing embankment. Ductile Iron Piles were selected as the most cost-effective solution allowing the work to proceed atop the existing narrow embankments. Exterior grouted Ductile Iron Piles were installed to penetrate the existing embankment fill and terminate in the underlying medium dense to very dense sand. The 16 piles were installed to depths of 55 feet in 2 days – working one day on each of the abutments. A site-specific tension load test was performed to verify the capacity of the grouted displacement pile. The Ductile Iron Pile solution was well suited for the limited access environment combined with the depths required to reach the underlying sand.

A new 11.5-ft by 16.5-ft pile-supported mat foundation was planned for a new pump station as part of a marine park improvements project. The foundation was planned at a depth of 16 feet below grade. Ground conditions consisted of very soft silt and clay extending to 55 feet followed by loose clayey sand to 70 feet. Medium dense to dense clayey sand and very stiff silt were then encountered below the weaker deposits. After an initial round of pricing revealed the original solution of 20 ton micropiles was over budget, the project team worked with DuroTerra to develop a Ductile Iron Pile solution to reduce foundation costs. An exterior grouted 10-inch diameter Ductile Iron Pile was driven to depths of 82 feet to penetrate upper soft deposits and terminate in the underlying competent sand and silt. The nine production piles were installed in a single day following a successful load testing program. After excavation to the foundation elevation, the piles were cut, capped and poured into the mat foundation. Besides providing cost savings on the project, the Ductile Iron Pile solution rapidly accelerated the schedule and easily facilitated installation to deep depths.