Contractor Spotlight – Deep Foundation Group

CONTRACTOR SPOTLIGHT – Deep Foundation Group

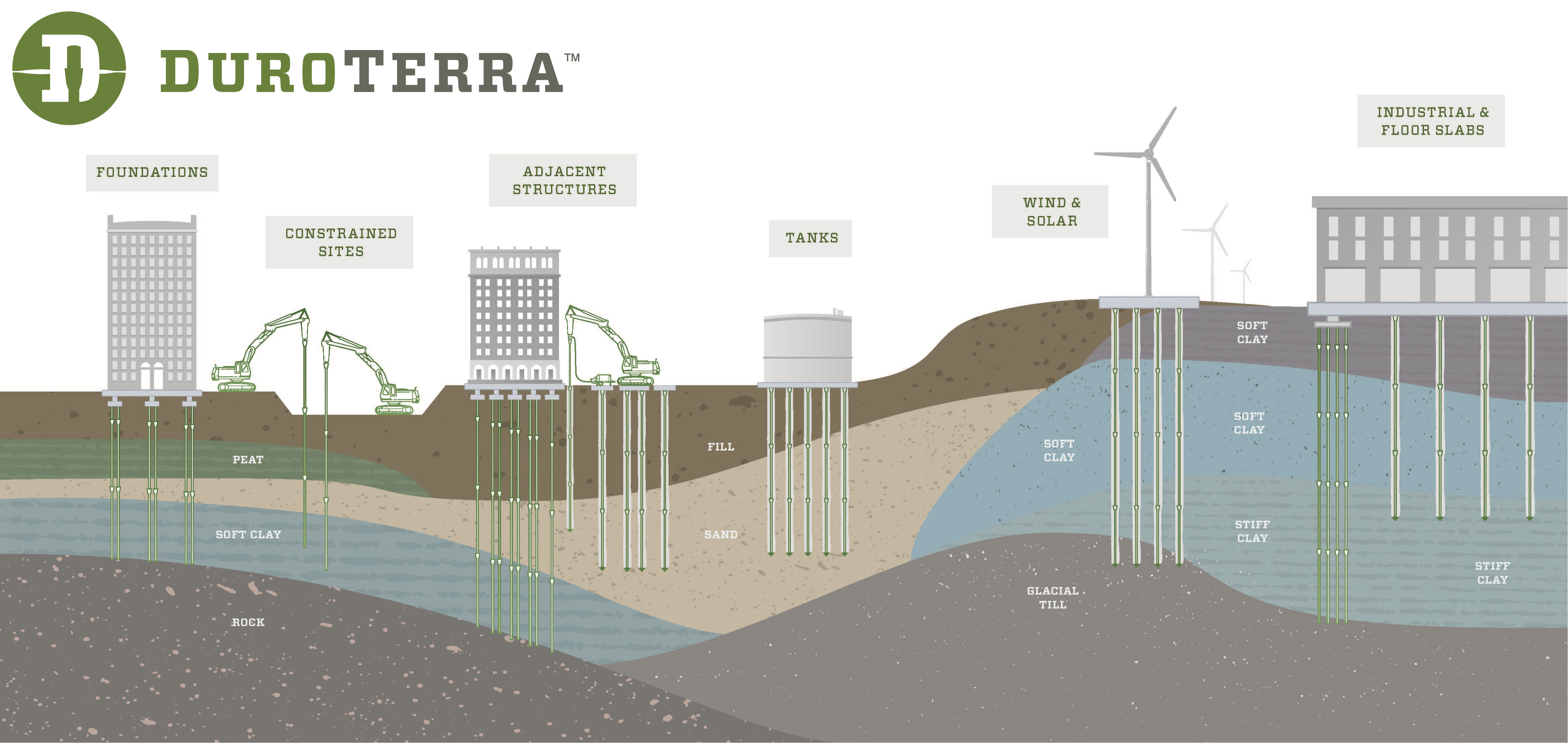

More and more project teams across the United States and Canada are selecting Ductile Iron Piles from DuroTerra to provide substantial value when addressing their deep foundation needs. Ductile Iron Piles are increasingly used on projects to save time and money, while substantially reducing the risk associated with other deep foundations. This work is only possible through the efforts of a growing network of outstanding specialty geotechnical contractors who install the system. We often like to highlight these companies and the work they are doing around North America to illustrate how TRM’s Ductile Iron Piles are Fast. Simple. Safe.™

With offices in Sioux Falls, SD and Mankato, MN, Deep Foundation Group (DFG) provides a range of specialty construction and engineering services throughout the Midwest. The company, founded by Structural Engineers Robbie Veurink, P.E. and Brent Krohn, P.E., has been performing geotechnical construction since 2018. Their services include pile installation (Ductile Iron Piles and helical piles), ground improvement (stone columns), load testing, structural shoring as well as structural engineering. Deep Foundation Group has a staff of six engineers who pride themselves on solving complex geotechnical and structural problems.

With offices in Sioux Falls, SD and Mankato, MN, Deep Foundation Group (DFG) provides a range of specialty construction and engineering services throughout the Midwest. The company, founded by Structural Engineers Robbie Veurink, P.E. and Brent Krohn, P.E., has been performing geotechnical construction since 2018. Their services include pile installation (Ductile Iron Piles and helical piles), ground improvement (stone columns), load testing, structural shoring as well as structural engineering. Deep Foundation Group has a staff of six engineers who pride themselves on solving complex geotechnical and structural problems.

DFG originally started looking at Ductile Iron Piles in 2020 as a system to add to their geotechnical toolbox. Specifically, they saw opportunities to use the low vibration driven pile system in situations with questionable soil conditions combined with relatively shallow bedrock. This would allow them to take advantage of the high pile capacity and offer installation speed and cost savings on projects. One such project recently constructed in Sioux Falls, SD illustrated some of those advantages (see below for more information). Their experiences with the system have been very favorable. “DuroTerra and their support is fantastic. They are very responsive and helpful. The Ductile Iron Pile system is a great tool to have in your pocket”, says Robbie Veurink.

INTERESTED IN BECOMING A DUCTILE IRON PILE INSTALLER?

DuroTerra works with a wide variety of geotechnical contractors across the U.S. and Canada – from local contractors to international geotechnical contractors on projects of all sizes. Our engineering and construction representatives can guide you with product information, equipment assessment and setup as well as project feasibility and pricing. Reach out to us today to learn more.

PROJECT HIGHLIGHT – Jacobson Plaza at Falls Park

The construction of a new $18.5M recreation facility in Sioux Falls, South Dakota included a 14,000 square foot outdoor ice skating ribbon, a warming house, splash pad, dog park and inclusive playground. Foundations for the warming house were designed as a series of grade beams supporting a structural slab. As a major Brownfield site that previously operated as a railyard maintenance facility and scrap metal salvage yard, ground conditions consisted of highly-variable, debris fill extending between 7 and 14 feet in the borings. The fill was underlain by topsoil followed by Sioux Quartzite bedrock. Foundation support using ground improvement was ruled out due to soil and groundwater contamination concerns. Helical piles presented risks with penetration of the debris fill and the possibility of spinning out at the abrupt fill/rock transition. Ductile Iron Piles were specified for the project with the low vibration piles designed to be driven through the variable fill to terminate on hard rock.

Deep Foundation Group was the selected specialty contractor for the pile installation. Given the late fall timing of the foundation work, it was critical for the construction schedule to remain ahead of winter conditions. On the first day, Deep Foundation Group installed a 13-foot long test pile to rock. Since the pile had sufficient structural capacity without interior grout, the load test was set up and performed immediately. Test results showed only 0.20 inches of movement at 90 kips (200% design load). DFG continued with production work and installed a total of 114 piles to depths up to 25 feet in only 2 days, averaging over 1,000 LF/day. All pile work including interior grouting and load testing was completed in only 3 days total to help the project stay ahead of winter weather. To learn more about the project, check out the full project summary.