DuroTerra Dialogue: Too much Tension?!?! – Not for Ductile Iron Piles

Too much Tension?!?! – Not for Ductile Iron Piles

There’s so much tension in the world these days. No – we’re not talking about the tension caused by global pandemic stresses or political differences. We’re talking about the tension on foundations caused by increased seismic overturning loads, wind pressures, retaining wall uplift loads or even structural configurations that result in tension demand on foundations.

You might be surprised to know that Ductile Iron Piles can offer a solution to resist high tension loads, in addition to compression loading. While the unique Plug-and-Drive (bell-spigot) connection forms a friction welded joint that has been shown to resist considerable tension loads, a more conservative design approach for tension resistance utilizes a high-strength threaded center bar to carry all of the tension demand. The center bar is wet-set inside the pile, within the cement grout to mobilize the pile’s perimeter grout-to-ground or interface frictional capacity when subjected to tension loads.

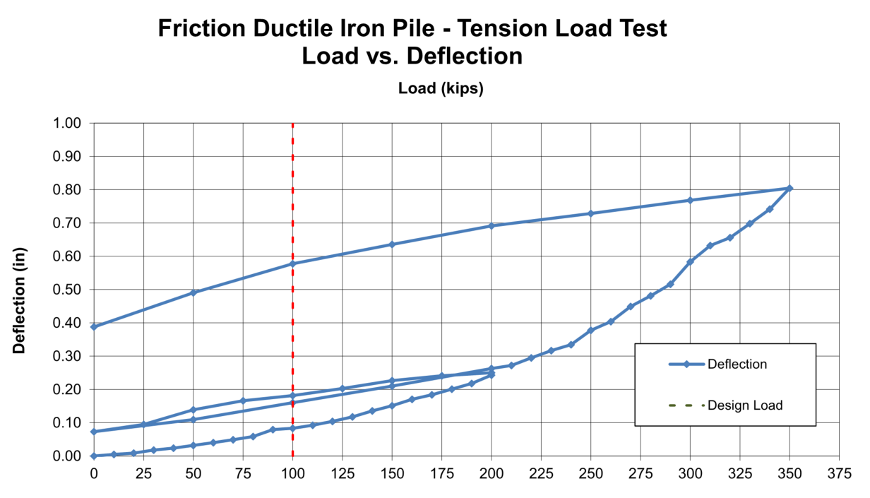

How much tension capacity can you actually achieve? That depends on several factors, including; soil conditions, pile length, pile diameter, center bar capacity, and whether the pile is installed with exterior grout or not. It’s as simple as evaluating the structural capacity of the center bar in tension and the geotechnical frictional capacity along the exterior of the pile. So…how much capacity? In a recent tension test program, an exterior grouted Ductile Iron Pile installed with a 10.6-inch (270 mm) diameter grout shoe achieved 350 kips without failing the 32-ft long pile. The test was stopped at 350 kips to avoid overstressing the center bar!

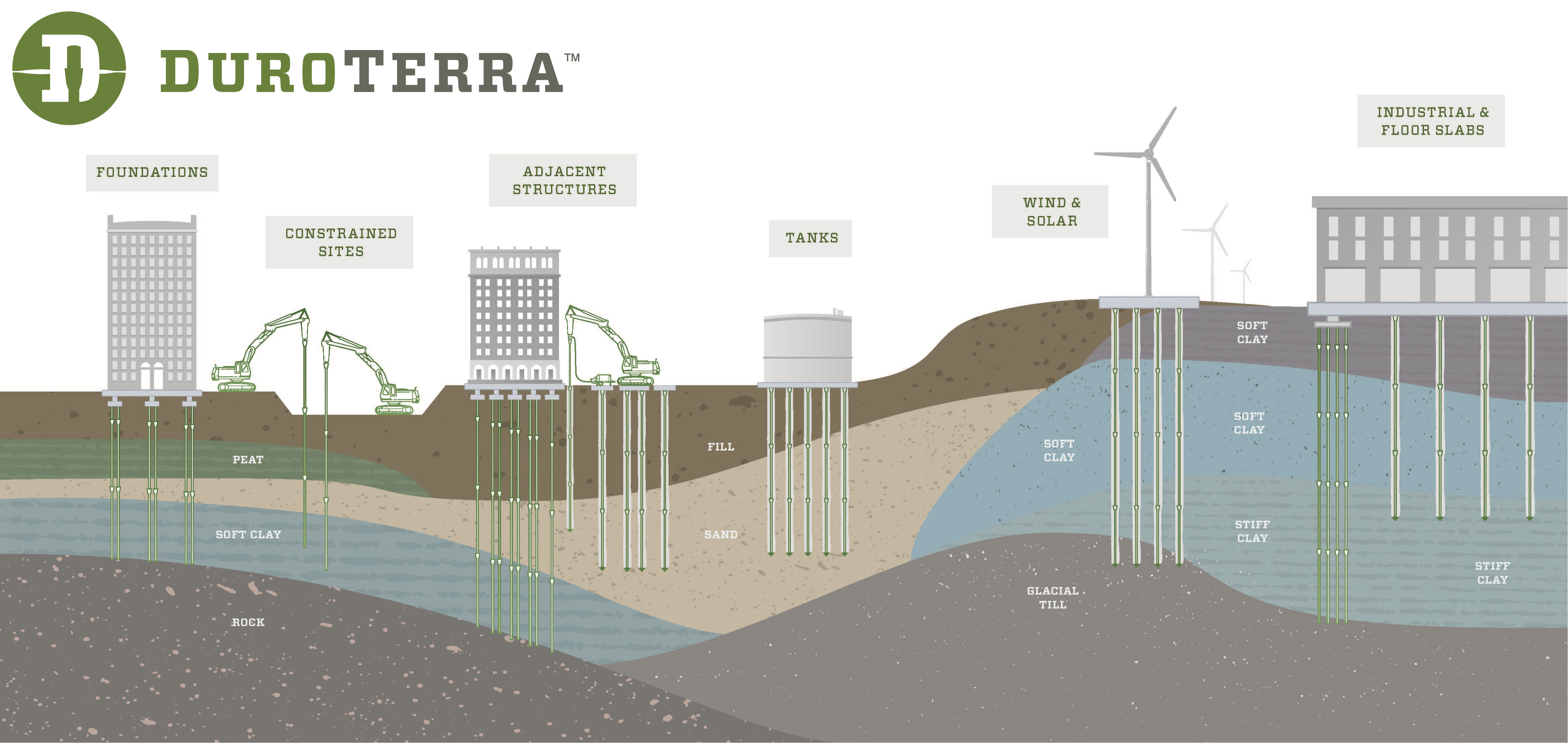

Many of the same benefits offered by the Ductile Iron Pile system for working on constrained sites also apply to tension resistance:

- Rapid installation

- Reduced cost compared with traditional micropiles

- Limited laydown requirements

- Mobile equipment for ease of working on tight sites or variable grades

Looking at a project with tension requirements or simply looking to learn more about tension or other DIP technical details or installation, please reach out. Want to learn more about tension applications – read on and see how we can all manage the tension a little easier. FAST. SIMPLE. SAFE.

Relevant projects

Ductile Iron Piles were used as an alternative to drilled micropiles to support the new bridge abutments for a single span bridge over the Metro North Railroad. DIPs replaced the micropiles on a 1:1 basis – delivering 100 ton working capacity in compression and 30 ton working capacity in tension. Pile performance was verified with full-scale load testing to 500 kips in compression and 150 kips in tension. The Ductile Iron Pile solution provided a low vibration solution to address the loading demands with a cleaner, faster and less expensive piling option.

Reconstruction of the Vermont State Office Complex required support of a lower level mat foundation that was subject to both compression demands as well as tension demands resulting from buoyancy. Ductile Iron Piles were used as a cost-effective alternative to 8-inch diameter drilled micropiles to meet the 20 ton tension demands.