Ductile Iron Piles provided a cost-effective, low vibration deep foundation solution developing capacity in the rock at more than 70 feet on an extremely constrained site.

Project Description:

The project involved the construction of a new 7-story, steel-framed condominium building on a 2,050 sq ft lot located a block from Boston’s TD Garden. Following demolition of an existing building, foundation work had to be completed on the narrow, 27-ft wide site bordered by an aging brick structure and a new 7-story condo. Concentrated loads along pile caps and grade beams were up to 200 kips (compression) and also included up to 90 kips (tension) in select locations.

Geotechnical Conditions:

Soil conditions consisted of up to 13 feet of “urban” fill followed by 17 feet of organic soils. The fill and organics were underlain by very stiff to very soft marine clay extending to depths of 70 feet where glacial till and weathered Cambridge Argillite were encountered. Groundwater was measured at a depth of about 10 feet below grade.

Project Challenges:

Provide a cost-effective, low vibration deep foundation solution developing capacity in the rock at more than 70 feet on an extremely constrained site.

Advantages

- Low vibrations

- Rapid installation and cost savings compared with micropiles

- Ability to work on constrained sites

- Demonstrated capacity through load testing

Design and Construction Solution

Poor soil conditions required the use of a deep foundation system to transfer building loads to the underlying rock. However, the urban location on a constrained site limited deep foundation options. Knowing about the successful use of Ductile Iron Piles (DIPs) as an alternative to drilled micropiles on the adjacent building, the geotechnical engineer recommended Ductile Iron Piles for foundation support. The structural engineer designed a series of pile caps and grade beams supported by DIPs with a capacity of 50 tons (compression) and 5 kips (lateral). In some locations, a tension capacity of 30 kips was needed. A total of 33 piles were designed.

McGue Excavating Contractors was awarded the combined package of sitework and Ductile Iron Pile installation. McGue worked with Geotechnical Consultants, Inc. to develop a design consisting of Series 170/9.0 Ductile Iron Piles driven to achieve “set” in the weathered rock. In locations requiring tension resistance, an exterior grouted DIP was designed using a 270 mm (10.6 inch) diameter grout shoe to form a 10-inch diameter grouted displacement pile. Exterior grouted piles were also driven to terminate on rock to develop compression capacity. After driving, a threaded centerbar was inserted full length into the tension piles to transfer the tension loads to the exterior-grouted DIP.

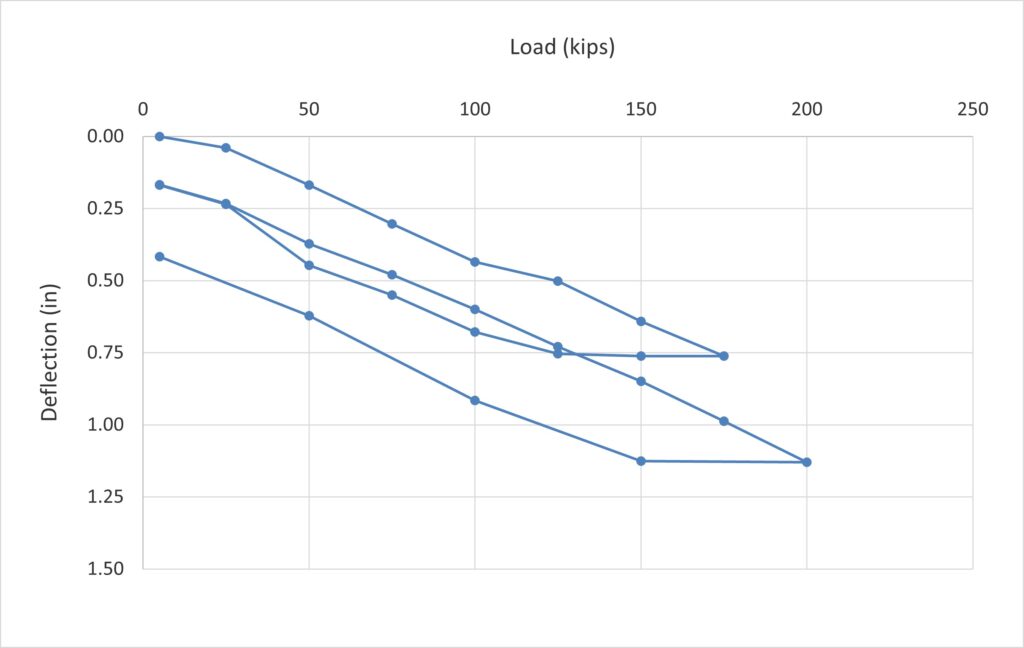

A pre-production full-scale compression load test program was performed on a sacrificial pile. Four (4) exterior grouted tension DIPs were installed as reaction piles. The test pile was driven to terminate on rock at approximately 76 feet. The load test was performed up to 200% of the design load (200 kips). After an unload-reload cycle due to a load test jack issue, a deflection of 1.13 inches was noted at 200%. The pile rebounded to 0.41 inches of net deflection upon unloading which included the 0.17 inches of deflection upon following the original unloading cycle. Both curves revealed elastic response of the test pile.

With the successful load test completed, the crew installed 33 production Ductile Iron Piles to depths of 63 to 89 feet (over 2,600 LF) in 4 days. The low vibration installation allowed for work immediately adjacent to the existing building with no adverse impacts. Besides the excavator/hammer, the crew used a mini-excavator with a grapple attachment to easily facilitate pile material handling on the tight site.

Project Team Members

DIP Installer: McGue Excavating Company

Geotechnical Engineer: KMM Geotechnical Consultants, LLC

Developer: GrayMac Properties, Inc.

Structural Engineer: Goldstein – Milano LLC