Ductile Iron Piles provided an economical, low vibration deep foundation solution.

Project Description:

Construction of this new 33,000 square foot gymnasium addition required demolition of the existing structure, followed by reconstruction of the new building between two existing structures supported by drilled shafts. Maximum column and wall loads for the new building are in the range of 100 kips and 8 kips per linear foot, respectively.

Geotechnical Details:

Subsurface conditions encountered at the site consist of an upper stratum of clay, silt and sand fill, extending to depths ranging from 3 to 9 feet. The fill is underlain by natural fine-grained soils with N values ranging from 2 to 15 encountered to depths of 13 to 18 feet followed by loose to dense sands to depths of about 50 feet in the borings.

Project Challenges:

Provide an economical, low vibration deep foundation solution to support new perimeter foundations without imposing new loads on the existing foundations and be compatible with interior shallow foundations on ground improvement.

Advantages

- Simple, low-vibration installation near existing structure

- Small diameter, high capacity load resistance

- Rapid turn-key operation (design through installation)

- Superior load test performance

- Low vibration during installation

Design and Construction Solution

Micropiles were designed for support of the two perimeter walls on either side of the gym addition that would abut the existing structures. Peterson Contractors proposed using Ductile Iron Piles as an alternative to the drilled micropile design.

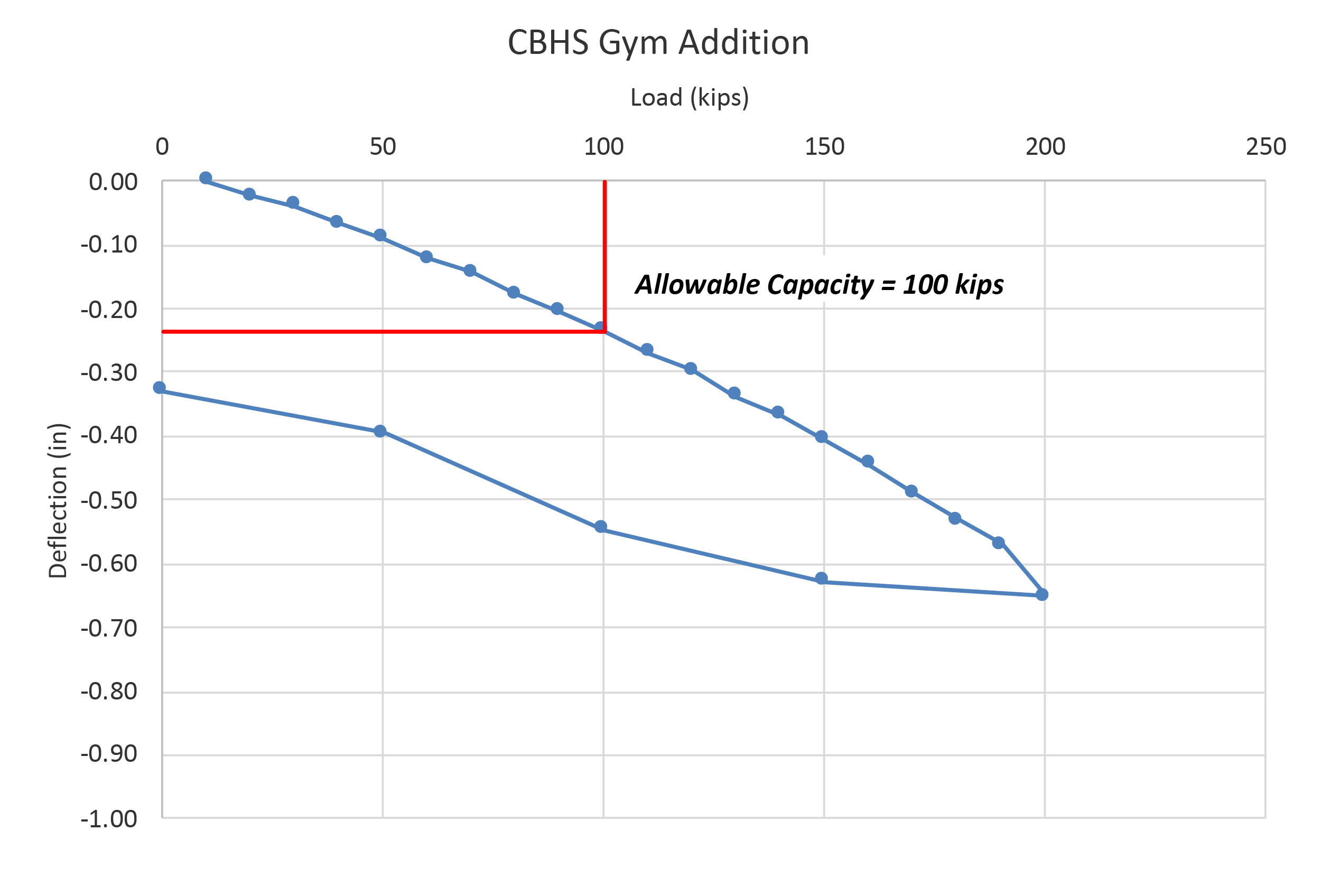

The Ductile Iron Pile design featured Series 118/7.5 piles (118 mm diameter with wall thicknesses of 7.5 mm) with an oversized 220 mm conical drive shoe. The oversized drive shoe creates an annular space during driving of the pile. Sand cement grout is continuously pumped through the grouting drive shank, down through the pile, and out through grout ports in the drive shoe to completely encapsulate the pile with grout during driving. The end result is a fully grouted pile that develops substantial grout-to-ground bonding for frictional capacity. The grouted piles were designed for allowable compression capacities of 100 kips, matching the capacity of the specified micropiles on a 1:1 basis.

Peterson Contractors, Inc. installed a total of 20 Ductile Iron Piles in addition to the ground improvement elements used for support elsewhere on the gym. All Ductile Iron Piles terminated at depths of 50 feet in the dense sandy soils. The DIP scope of work was installed in less than 2 days. Load testing was performed on a non-production Ductile Iron Pile. The test results confirmed acceptable performance results and showed less than ¼-inch of movement at the design load of 100 kips and less than ¾ inch of deflection at the ultimate load of 200 kips. The project demonstrates how the use of the Ductile Iron Piles are an effective supplement to micropile systems to solve a variety of design challenges.

Project Team Members

DIP Installation Partner: Peterson Contractors, Inc.

DIP Design Partner: Geopier Foundation Company

Geotechnical Engineer: Geotechnology

General Contractor/ Developer: Linkous Construction

Structural Engineer: Scallion Structural Engineering