Introduction:

A new 10,000 square foot outpatient medical office building was planned on Front Avenue in West Haven. Design of the foundation system consisted of a series of pile caps and grade beams. Foundation loads ranged from 70 and 210 kips per the original foundation plans.

Geotechnical Conditions:

Soil conditions, based on three borings performed at the site, consisted of highly variable conditions. Fill containing sand, silt, gravel, organics, cobbles and construction debris was encountered at Borings B-1 and B-3 to depths of up to 15 feet. A 10-ft thick layer of organic silt was encountered below the fill at Boring B-3. The fill and organics (where encountered) were underlain by medium dense sand to the maximum explored depth of up to 42 feet. At Boring B-2, no fill or organics were encountered and soils consisted of medium dense sand encountered from the ground surface to maximum explored depth of 37 feet. Groundwater was encountered only a few feet below grade.

Project Challenges:

Providing cost-effective deep foundation support on a site with highly variable geotechnical conditions.

Advantages

- Rapid mobilization

- Quick installation

- Easily adjust lengths to penetrate variable fill and organics

- High capacity to replace 12-3/4 inch steel pipe piles

Design and Construction Solution:

The geotechnical engineer considered numerous deep foundation options including timber piles, concrete-filled steel pipe piles and augercast piles. Final foundation plans specified 12-¾ inch diameter, concrete-filled steel pipe piles with a working capacity of 70 kips developed in friction.

Helical Drilling was approached by the design/build team to provide a foundation support solution that could be rapidly designed, mobilized and installed. After reviewing the variable conditions and the foundation design, Helical proposed a solution consisting of Ductile Iron Piles designed for 70 kips working capacity to replace the pipe piles on a 1:1 basis. The solution was accepted based on cost, the quick response to design and mobilize and rapid production rates.

The Ductile Iron Pile design consisted of a friction pile using a Series 118/7.5 (118 mm diameter with 7.5 mm wall thickness) pile with an oversized 220 mm conical grouting shoe. The Ductile Iron Piles were advanced using a high frequency percussion hammer that results in minimal vibrations compared with traditional pile driving. During installation, the oversized cap and pile were advanced while continuously pumping sand cement grout to immediately fill the annular space created by the oversized cap. Piles were advanced through the fill and organics to develop a friction bond zone in the underlying medium dense sand layer. Helical’s QA/QC team monitored penetration rates while driving to determine when the fill and organics were penetrated to then ensure that the minimum bond length of 15 feet in the sand was achieved. In limited areas, piles were lengthened to account for softer conditions potentially reflecting deeper organics.

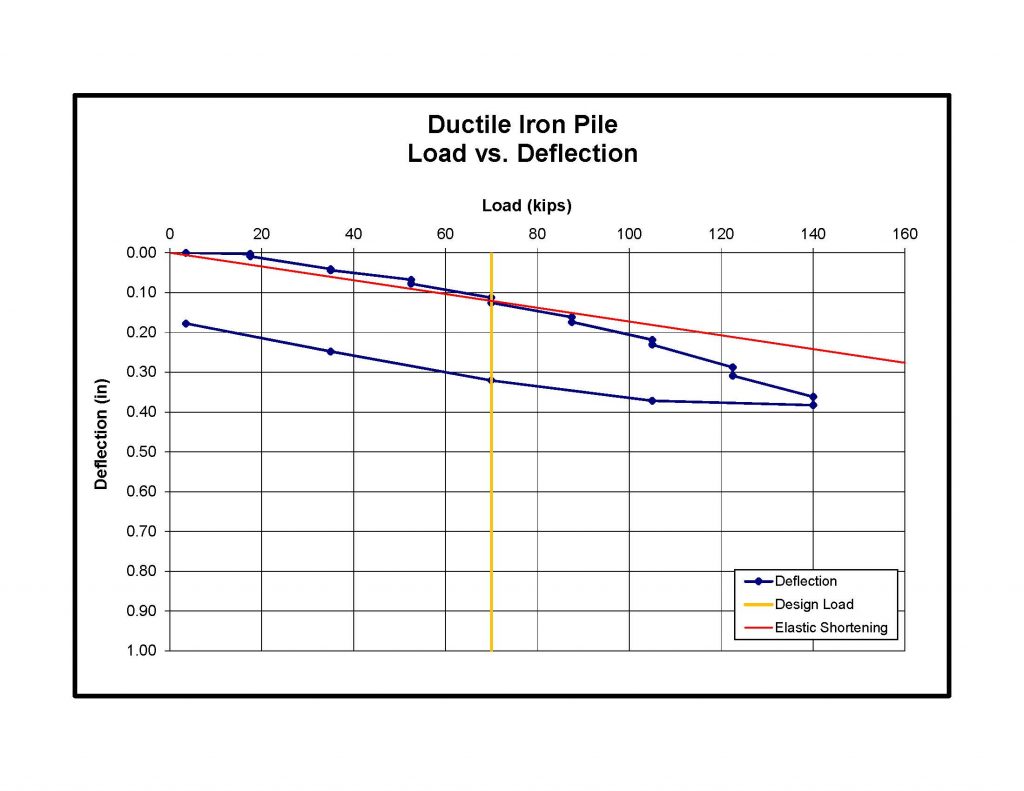

A full-scale compression load test was performed to 200% of the design load. Results showed a little more than 0.1 inches of movement at the 100% design load (70 kips) and less than 0.4 inches at the 200% design load (140 kips). Permanent deformation of about 0.18 inches was recorded after unloading.

A total of 82 piles were installed on the project with average lengths of about 36 feet. The piles were installed and load tested in 7 working days on the site.

Project Team Members

DIP Design/Build Partner: Helical Drilling, Inc.

Geotechnical Engineer: The Geotechnical Department, LLC

General Contractor: Pustola & Associates Engineers/Constructors

Structural Engineer: Pustola & Associates Engineers/Constructors