Ductile Iron Piles provided foundation support using a low vibration, driven pile solution that could accommodate variable limestone depths across the site while limiting disruption to the existing school and minimizing schedule and costs.

Project Description:

The Pasco County School District in New Port Richey, Florida constructed a new high school addition on the existing campus of Gulf High School. The new 2-story construction occupied a footprint of approximate 90,000 sf. Column and wall loads for the new building were as high as 250 kips and 7 kips per linear foot, respectively. Tension loads of up to 15 kips were also expected.

Geotechnical Conditions:

Subsurface conditions encountered at the site consist of 4 to 12 ft of loose to medium dense sand and clayey sand, underlain by soft to very stiff clay to depths of 20 to 32 feet. Limestone bedrock was generally encountered below the clay at depths ranging from 22 to 37 feet in the borings, although zones of weathered limestone were encountered in the upper 15 feet in some borings.

Project Challenges:

Provide foundation support using a low vibration, driven pile solution that could accommodate variable limestone depths across the site while limiting disruption to the existing school and minimizing schedule and costs.

Advantages

- Adaptable to highly variable bedrock elevations

- Simple, low-vibration installation near existing structures

- Small diameter, high capacity load resistance

- Rapid turn-key operation

Design and Construction Solution

The combination of the heavy building loads and poor subgrade soils lead the design team to consider deep foundation options for the new structure. Driven pipe piles were initially considered but were ruled out due to excessive vibrations associated with traditional pile driving activities. Ductile Iron Piles (DIPs) were eventually chosen to provide similar deep foundation performance, with vibration levels that would fall well below maximum acceptable tolerances. Earth Tech was selected to install the Ductile Iron Pile system.

The Ductile Iron Pile design featured Series 118/7.5 piles (118 mm diameter with wall thicknesses of 7.5 mm) that would be installed via the dry-method (non-grouted exterior) to bear on competent limestone. Earth Tech engineers designed the DIPS for allowable compression capacities of 50 kips, tension capacities of 5 kips, and lateral capacities of up to 5 kips. Full-length center bars were wet-set into the interior-grouted piles to meet tension demand at select locations.

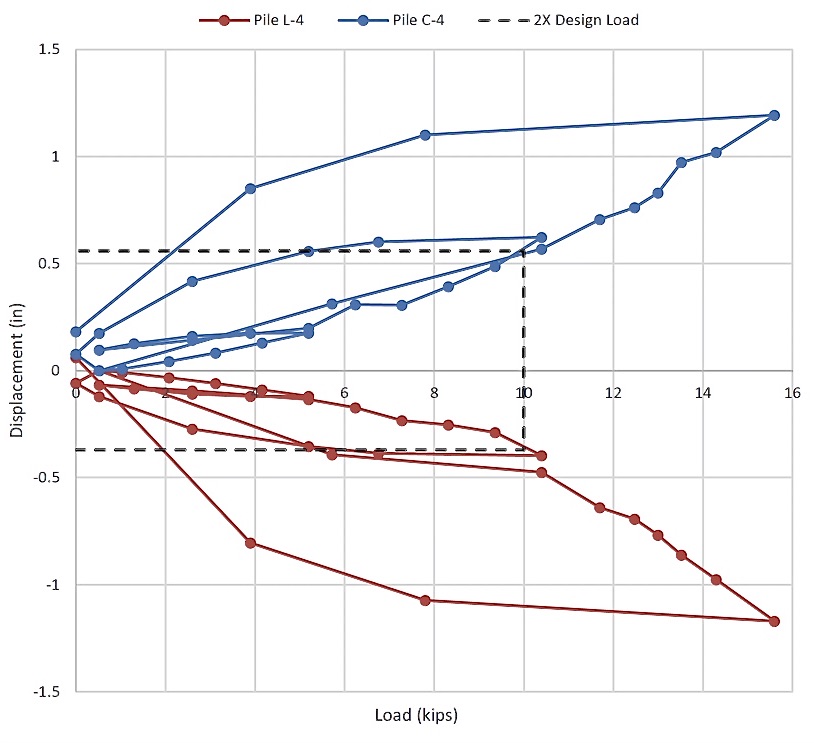

Earth Tech installed a total of 853 Ductile Iron Piles to depths ranging from 10 to 90 feet (32-ft average) with minimal pile waste due to the Plug and Drive connection. Many piles advanced with only the hydraulic crowd force of the excavator, then were completed by driving those piles to the specified set criteria. The result was an accelerated production pace, averaging around 900 linear feet per day. Earth Tech performed compression, tension, and lateral testing on the non-grouted (exterior) piles to validate their design. Compression testing on a 31-ft. pile resulted in total deflections of 0.17” at 50 kips (100% design) and 0.43” at 100 kips (200% design). Tension testing on a 25-ft. pile resulted in only 0.014” deflection at 5 kips (100% design) and 0.024” at 10 kips (200% design.) The tension test was extended to 37 kips, with no signs of pull-out or any other type of geotechnical or structural failure. Lateral testing resulted in an average displacement of 0.15” at the design load and 0.47” at twice the design load. All test results confirmed the design assumptions and exceeded performance expectations.

Project Team Members

DIP Installation Partner: Earth Tech

Geotechnical Engineer: Universal Engineering Sciences

General Contractor: Williams Company – Tampa

Structural Engineer: Long & Associates