Ductile Iron Piles provided a solution to transfer building loads below the urban fill and organics while also developing sufficient buckling capacity from confinement loss due to the adjacent excavation.

Project Description:

The 6 Stack Street Pavilion is a part of the Hood Park redevelopment effort featuring mixed-use residential and commercial construction with office, lab and institutional space. The 6 Stack Street portion includes a single-story pavilion that functions as a bicycle storage area and also includes an elevated green space and pedestrian bridge connecting the green space to the green roof deck of the structure.

Geotechnical Details:

The soil conditions consisted of heterogeneous urban fill with obstructions extending to depths of about 18 feet followed by a 4-foot thick peat and organic layer. Marine and glaciomarine sand and clay then extended to depths of about 38 feet at which point medium dense to very dense glacial till was encountered. Groundwater was anticipated between 10 and 15 feet below grade.

Project Challenges:

Provide a solution to transfer building loads below the urban fill and organics while also developing sufficient buckling capacity from confinement loss due to the adjacent excavation.

Advantages

- Low cost and ease of mobilization

- Rapid and safe installation procedure

- Development of capacity in friction

- Cost savings compared with other displacement piles

- Low vibration during installation

Design and Construction Solution

In the planning stages, the project involved multiple challenges related to poor soil conditions coupled with the surrounding structures and ongoing construction. Geotechnical engineers needed to identify a low-vibration, cost-effective foundation solution to deliver the load-carrying capacity in the poor soils while also limiting the foundation performance risks associated with the neighboring future excavation. Traditional options like micropiles and driven piles were considered, but eliminated due to cost and vibrations, respectively. Proprietary displacement piles and Ductile Iron Piles were specified for the project and competitively bid. Ductile Iron Piles were selected based on the high production rates, limited lead time for material and cost-savings.

DuroTerra designed a solution consisting of 8-inch diameter grouted friction piles to penetrate the fill, organics and marine / glaciomarine soils to terminate in the glacial till. A Series 118/9.0 Ductile Iron Pile (118 mm outer diameter and 9 mm wall thickness) installed with a 220 mm grouting shoe was used to deliver a 40 ton (compression) capacity for design. Phoenix Foundation Company bid the piling scope of work and was selected by the project General Contractor.

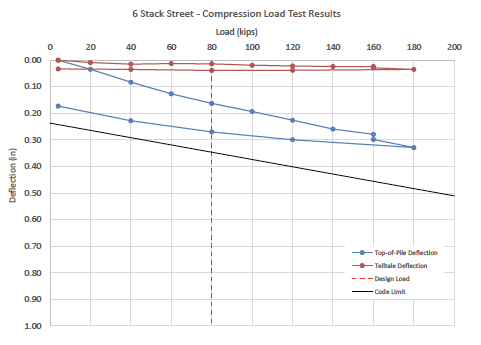

The piles were advanced using an Atlas Copco MB 1700 percussion hammer mounted on a Kobelco SK230SR excavator. Sand cement grout was mixed on-site with a mobile mixer. The project started with the installation of a test pile and four tension reaction piles. The test pile was driven to a depth of 41 feet. Following a 6 day wait period, the test pile was load tested to 180 kips (225% of the design load). The test results showed only 0.33 inches of deflection at the maximum test load and strain gauges confirmed adequate load transfer to the bond zone.

Phoenix immediately moved into production installation for the project. They installed a total of 128 production piles in 9 working days averaging about 15 piles per day. At average production of about 600 LF/day, Ductile Iron Pile installation was considerably faster and simpler than a traditional drilled micropile system. “The technical support provided by DuroTerra was exceptional. This product was relatively new to the design team and because of DuroTerra’s support, the installation and execution was done seamlessly. The installation was executed in only 2 weeks – cutting the project schedule in half,” noted Shane O’Neill who manages operations for the Phoenix.

Project Team Members

DIP Installation Partner: Phoenix Foundation Company, Inc.

DIP Designer: DuroTerra, LLC

General Contractor: Lee Kennedy Company, Inc.

Geotechnical Engineer: Haley & Aldrich, Inc.

Structural Engineer: McNamara Salvia

Architect: Elkus | Manfredi Architects