Ductile Iron Piles provide cost-effective and rapid foundation support for new interior mezzanine foundations

Project Description:

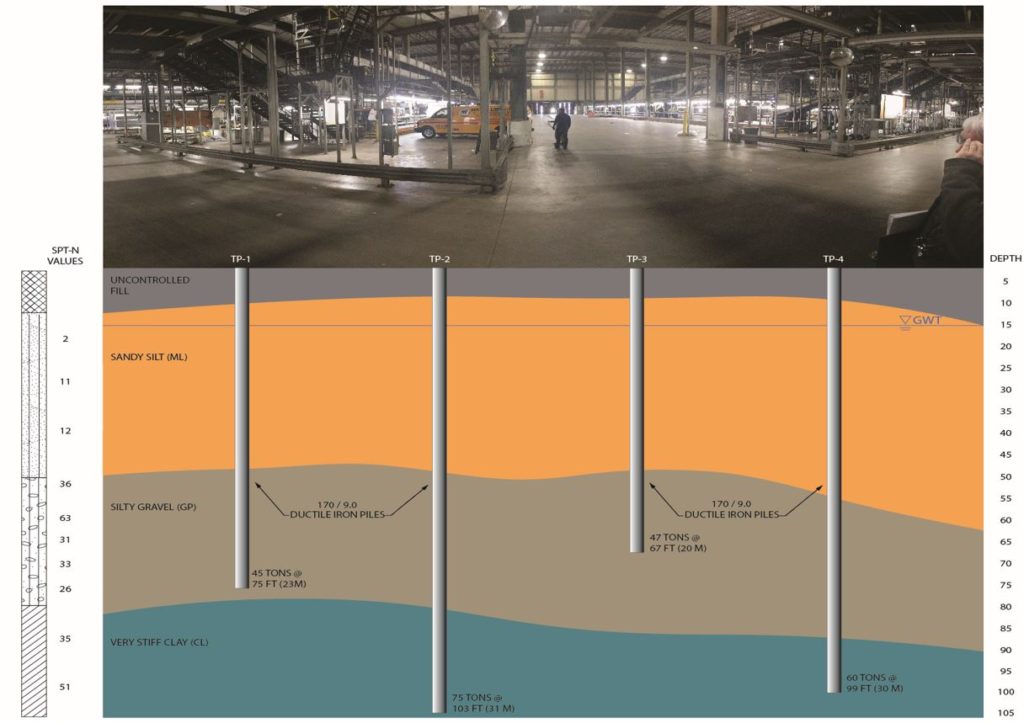

The project consisted of construction of a mezzanine expansion within the one million square foot logistics warehouse adjacent to the Philadelphia International Airport. Overhead clearances ranged from 20 to 35 feet within the existing facility. A total of 74 new foundation locations were required for the mezzanine. Footing loads were up to 516 kips (compression) and 36 kips (lateral).

Geotechnical Conditions:

Soil conditions consisted of sand fill up to 10 feet below grade followed by a stratified soft/loose alluvial deposit comprised of sand, silt and clay extending to about 65 feet. The loose layer was underlain by medium dense to very dense sand and gravel with SPT N-values ranging from 18 to 79 bpf that extended to hard residual clay at depths of 85 to 90 feet. Groundwater was 7 to 8 feet below grade.

Project Challenges:

Provide cost-effective and rapid foundation support for new interior mezzanine foundations while working within limited overhead clearance areas and around active distribution facility operations.

Advantages

- Low overhead clearance for interior construction

- Rapid installation compared with micropiles

- Substantial cost savings compared with other pile systems

- Low mess and disruption to active operations

- Low vibrations

Design and Construction Solution:

Based on site logistics, overhead clearances, working around active facility operations and having several similar projects successfully utilizing Ductile Iron Piles, the project team worked closely with DuroTerra during the design phase to evaluate feasibility and develop construction plans and specifications for foundation support using TRM’s Ductile Iron Piles. Two sets of design capacities were initially estimated for Ductile Iron Piles. One capacity for piles installed to terminate in the sand and gravel layer to match the original pile-supported foundations and a higher capacity for piles installed deeper to terminate in the hard residual clay.

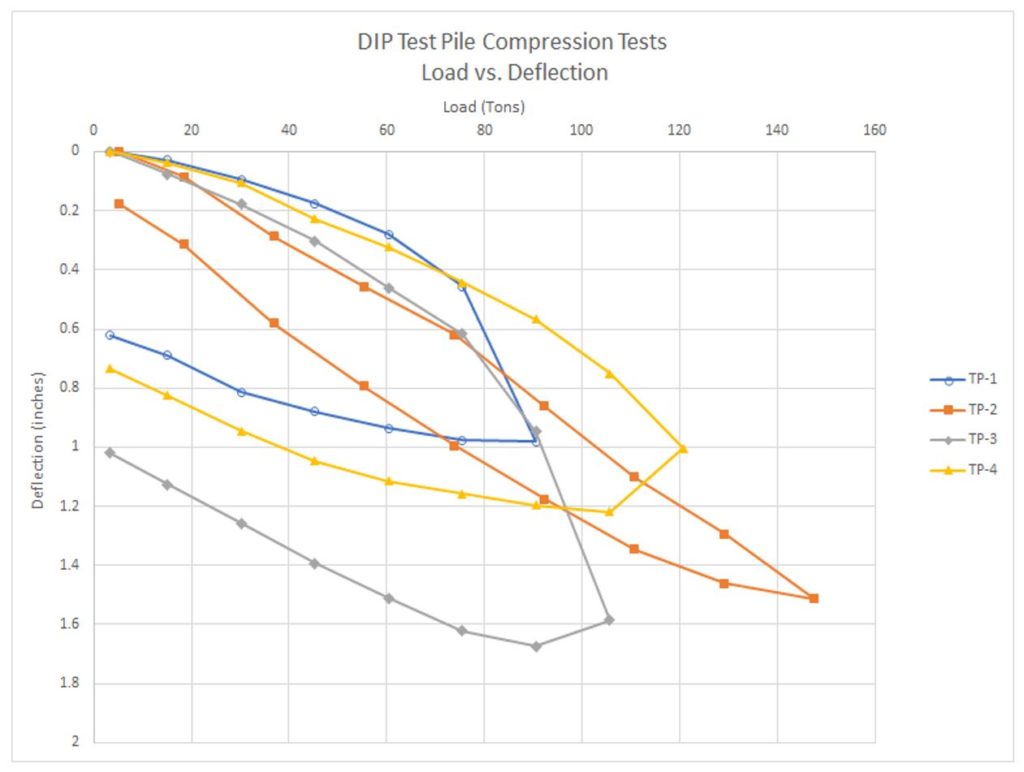

GeoStructures, Inc. developed a Ductile Iron Pile design featuring Series 170/9.0 piles (170 mm outer diameter with 9 mm wall thickness). A total of 288 piles were required to support the new foundations. Designers recognized that the piles would likely achieve reduced set times in the sand and gravel layer and would penetrate to the deeper residual clay layer to develop greater set rates and capacities. A pile load test program was developed to evaluate the load capacity of the piles corresponding to various set times and depths. Results of the test program confirmed working capacities of 45 tons with set times of only 2 seconds/inch in the sand and gravel layer. Greater working capacities of 60 tons and 75 tons were measured in the residual clay at set times of 7 seconds/inch and 50 seconds/inch, respectively.

Logistical coordination on the site was imperative. Immediately prior to work at each new pile location, the existing floor slabs were saw-cut and removed, followed by excavation to the bottom of pile cap elevation. The piles were then installed at each prepared location. Since the facility mainly operated on the 2nd and 3rd shifts, pile crews commenced installation during a modified daytime schedule that avoided impact to other areas in the one shift. All equipment (hoses, wires, cables, etc) were required to be removed between shifts – leaving an unobstructed facility access in the midst of the construction. In total, 288 Ductile Iron Piles were installed in about 4 weeks using 2 crews. Piles were driven to depths ranging from 67 to 103 feet and developed working capacities ranging from 45 to 75 tons. In limited overhead areas, the standard 5 meter long pile sections were cut to provide access and drive-on couplers were used to connect the shortened sections.

Project Team Members

DIP Design/Build Partner: GeoStructures, Inc.

Geotechnical Engineer: Dynamic Earth, LLC

General Contractor: CVM Engineers

Structural Engineers: CVMNEXT Construction