Ductile Iron Piles provided an economical deep foundation system to resist the applied canopy loads while limiting vibrations and working within low headroom conditions.

Project Description:

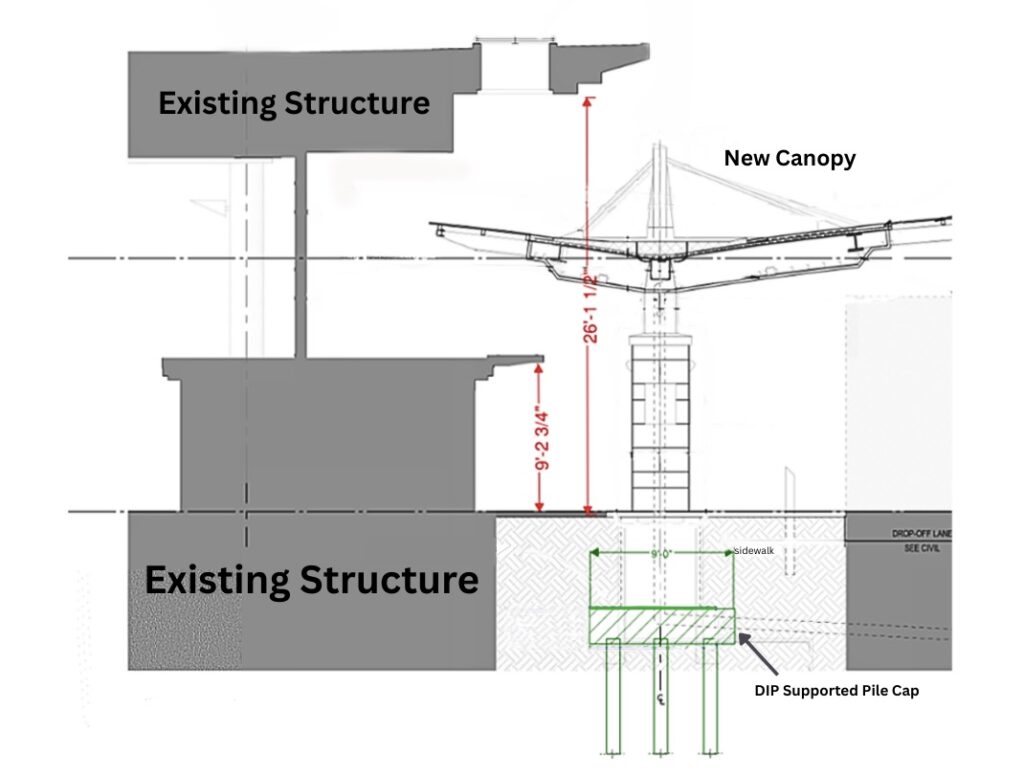

The new departure gate curbside canopy at the Bill and Hillary Clinton National Airport in Little Rock, AR is a concrete cantilever structure. The new canopy is 288 ft long and supported on a single line of 9 columns, with roof structures cantilevered 20 to 25 ft in each transverse direction. Canopy foundation loading conditions were 70 kips (static compression) as well as added compression/tension loads resulting from overturning moments up to 590 ft-kips. Pile caps were designed to bear 8 to 10 feet below grade. The new canopy was planned immediately adjacent to the existing, smaller canopy with overhead clearances ranging from only 9 feet up to 26 feet in locations.

Geotechnical Conditions:

Subsurface conditions at the site consist of fill (syentie crusher fines, locally known as “Donna” fill) to 7 feet. The fill is underlain by firm to stiff clay or loose to medium dense silt and sand to 30 feet followed by medium dense to very dense sand. Perched groundwater was encountered at depths ranging from 4 to 6 feet, with the static groundwater level noted at depths of 24 to 25 feet.

Project Challenges:

Provide an economical deep foundation system to resist the applied canopy loads while limiting vibrations and working within low headroom conditions.

Advantages

- Simple, low-vibration installation near existing structure

- Low-headroom installations at variable sub grade elevations at a busy, international airport

- Small diameter, high capacity load resistance

Design and Construction Solution

The geotechnical report provided foundation improvement options that included Ductile Iron Piles (DIPs), low-headroom auger-cast piles, and aggregate piers. The footing size required for the aggregate pier option required lengthening the footing, which would require work below the 9-ft vestibule clearance area. Low-headroom auger-cast piles would have resulted in a slow production schedule and a costly solution.

The Ductile Iron Pile solution was chosen for several reasons: 1) the pile caps associated with the Ductile Iron Pile option were small enough that it did not require installations under the 9-ft vestibule, 2) the typical DIP equipment could accomplish installation in the lower headroom scenario below the 26-ft clearance of the existing canopy, 3) the DIPs could be installed with a medium-sized excavator that could easily install piles in the 8 to 10 foot deep pile cap excavations and 4) the modular DIP sections were stockpiled in small areas and didn’t require multiple deliveries of aggregate and concrete, greatly reducing disruption of passenger traffic to the airport.

The Ductile Iron Pile design featured Series 118/7.5 piles (118 mm diameter with wall thicknesses of 7.5 mm) with an oversized 220 mm conical drive shoe. The exterior grouted piles were designed to be installed to depths of 45-ft, with a compression demand of 46 kips compression and a tensile demand of 30 kips per pile. A total of 8 Ductile Iron Piles were required for each of the 9 foundation locations. Chris-Hill Construction was awarded the work. Compression load testing of the DIPs validated the design capacity of the Ductile Iron Piles and Chris-Hill Construction installed the 72 Ductile Iron Piles with a Volvo EC290 and an Okada TOP 270 percussion hammer.

Project Team Members

DIP Installation Partner: Chris Hill Construction

Geotechnical Engineer: UES

General Contractor: Baldwin & Shell

Structural Engineer: SGH