Ductile Iron Piles provided a cost-effective deep foundation for the new foundations that could take advantage of the strong limestone bedrock and that would be minimally impacted by the thick stratum of soft, saturated clay.

Project Description:

The Watkins Institute in Nashville, Tennessee occupies a footprint of over 100,000 square feet and is a 4-to 5-story structure. The building consists of apartment and condominium housing wrapped around a cast-in-place concrete parking garage. The structural foundation system for the residential portion of the structure consists of a post-tension slab on grade that required deep foundation support. Support of the heavily-load parking garage structure also required deep foundations.

Geotechnical Conditions:

Subsurface conditions encountered at the site consist of an upper stratum of soft to stiff clay fill ranging from 3 to 13 feet. Below the fill, very soft to soft soil conditions were encountered to depths ranging from 6 to 35 feet. Medium dense to dense sands were encountered in some borings below the soft clay. Very hard limestone bedrock was encountered at the site at depths ranging from 36 to 46 feet in the borings. Groundwater was encountered at depths ranging from 10 to 24 feet in the borings. The combination of deep soft clay and heavy column loads drove the design team to consider deep foundations for the project.

Project Challenges:

Provide a cost-effective deep foundation for the new foundations that could take advantage of the strong limestone bedrock and that would be minimally impacted by the thick stratum of soft, saturated clay.

Advantages

- Small diameter, high capacity load resistance

- Adaptable to variable bedrock conditions

- Eliminated cost and schedule risks associated with drilling in very soft clay

- Rapid turn-key operation (design through installation)

- Superior load test performance

Design and Construction Solution

Ductile Iron Piles were recommended by the geotechnical consultant along with drilled piers for foundation support. The original plan was to use drilled piers for all foundations. However, the challenges with drilling in the soft, saturated clay resulted in a drilled pier budget and construction duration that caused the project team to seek other options. The project team turned to the Ductile Iron Pile approach for support of the large residential portion of the structure to help save foundation costs and time. Multiple sizes of Ductile Iron Piles were utilized to optimize the foundation support solution. The design featured Series 118/9.0 piles (118 mm diameter with wall thicknesses of 9.0 mm) for loads up to 50 tons and Series 170/9.0 (170 mm diameter with wall thicknesses of 9.0 mm) for loads up to 90 tons. Both pile types were installed via the dry-method (non-grouted exterior) and used heavy-duty driving shoes to develop capacity in end-bearing on the limestone bedrock.

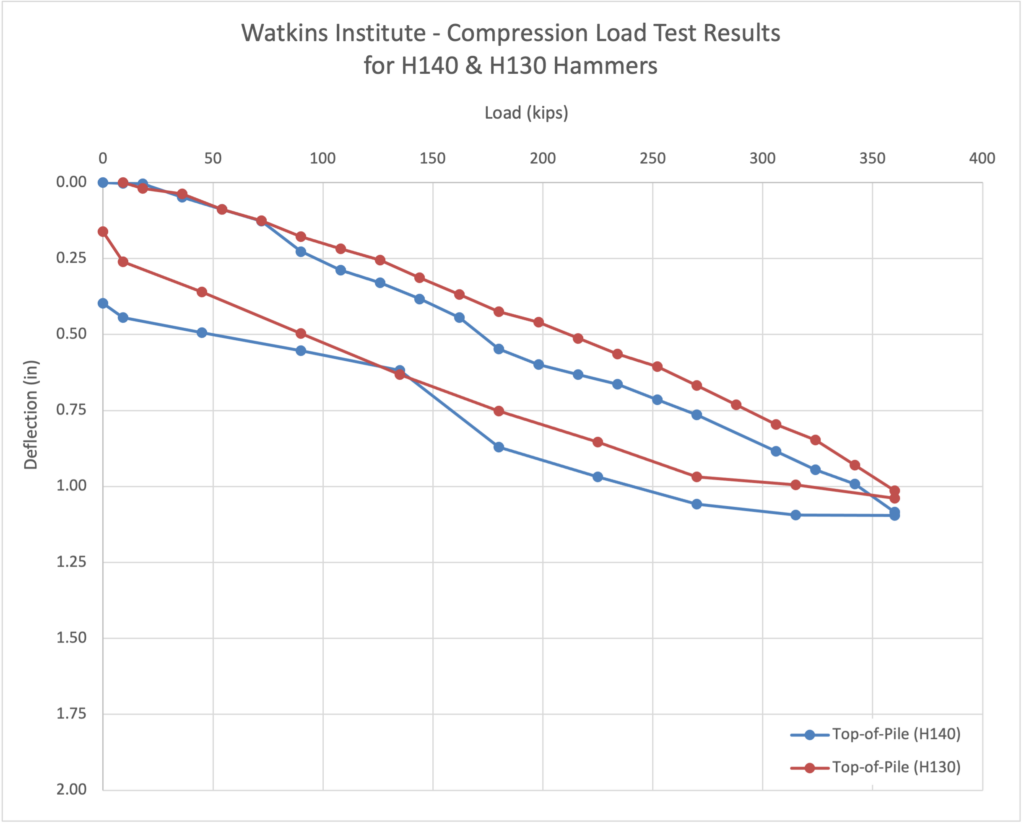

Peterson Contractors, Inc. (PCI) installed a total of 196, 50 ton DIPs and 339, 90 ton DIPs for the project. Pile lengths ranged from 38 to deeper than 100 ft, revealing unexpected variability in the top of bedrock elevation. Load testing was performed on non-production Ductile Iron Piles, utilizing two different percussion hammers with different energy class ratings to verify performance. Both tests revealed similar load-deflection responses that validated the design capacities and gave PCI equipment flexibility on the project. A total of 535 piles were installed to depths ranging from 25 to more than 100 feet, resulting in average production rates on the order of 800 to 1,000 LF/crew day.

Project Team Members

DIP Install Partner: Peterson Contractors, Inc.

Geotechnical Engineer: GEOServices, LLC a Universal Engineering Company

General Contractor: Franklin Construction

Structural Engineer: Genesis Engineering