Can Piles Be Rigid Inclusions?

To answer this question, first consider how the use of Ground improvement (GI) and Rigid Inclusions (RIs) for settlement control has changed the geotechnical industry over the last couple of decades. Because of the cost-savings and efficiencies associated with shallow foundation design supported by rigid inclusions, we often get asked […]

Structural Design of Ductile Iron Piles in Compression

Ductile Iron Piles have been used on a wide range of projects in the United States and around the world to support allowable axial compression loads ranging from 25 tons to more than 100 tons. Like traditional pile systems, the design capacity of Ductile Iron Piles in compression depends on […]

Project Experiences and Resources for 2024

Project teams across North America are increasingly taking advantage of the benefits offered by Ductile Iron Piles. Our customers continue to bring value to projects using the low vibration, modular driven pile system on sites with constrained access, limited overhead, vibration concerns, variable rock depths and other challenges. Curious where […]

Hot Topics of 2023

Looking ahead to 2024, we wanted to express our gratitude for the opportunities to be a part of your project successes. We hope you have a fantastic holiday season and wish you good health, happiness, and prosperity in the coming year! Before we bid farewell to 2023, we hope you […]

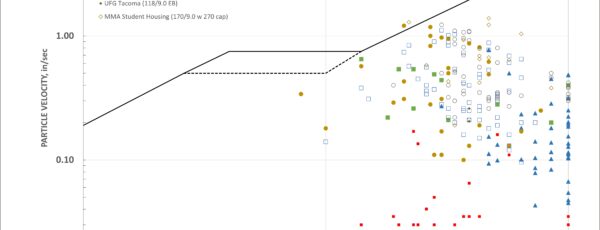

A Low Vibration Solution with Driven Ductile Iron Piles

Traditional driven piles are often associated with high vibration installations. As Jerry Lee Lewis might have sung “there’s a whole lotta shakin’ going on.” But that’s not the case with TRM’s Ductile Iron Piles – a low vibration driven pile system. Instead, it’s more like the Beach Boys singing “Good…good….good…Good Vibrations.” That’s right – Ductile […]

Are you torqued out with Helical piles?

Helical piles are a good tool for underpinning existing structures and supporting new boardwalks and lightly loaded buildings. Like any piling system, there can be limitations that impact the overall benefit. We often hear these common concerns from design professionals and contractors on projects considering helical piles. What if I don’t […]

Micropiles Made Simple

Micropiles fill a niche in geotechnical construction to address sites with challenges including vibration concerns, overhead clearance restrictions and heavily-obstructed conditions. But you often hear words like expensive, slow, messy, complicated, dangerous associated with micropile installations. Did you know that Ductile Iron Piles (DIPs) are being used more and more by project teams […]

What Equipment is Needed to Become a Ductile Iron Pile Installer?

WHAT EQUIPMENT IS NEEDED TO BECOME A DUCTILE IRON PILE INSTALLER? This is a common question that is asked by many geotechnical specialty contractors across the U.S. and Canada. Unlike other foundation systems that require expensive, purpose-built specialty machines, Ductile Iron Piles (DIPs) have been installed for more than 40 […]

Resources and Project Experiences from Recent Publications and Technical Briefs

Project teams across North America continue to add value with Ductile Iron Piles on some very interesting projects. We are fortunate that our customers enjoy sharing their project experiences as much as we do! In 2022, we teamed with some of these customers to prepare case histories, technical papers and white papers […]

Take a look at some of our interesting projects from 2022

As 2022 draws to a close, DuroTerra reflects on some of our more interesting projects from the past year. Thanks to all the engineers, designers, and contractors that helped make 2022 our busiest year ever. We are already looking forward to 2023 to provide you with Ductile Iron Pile products […]