What Equipment is Needed to Become a Ductile Iron Pile Installer?

WHAT EQUIPMENT IS NEEDED TO BECOME A DUCTILE IRON PILE INSTALLER?

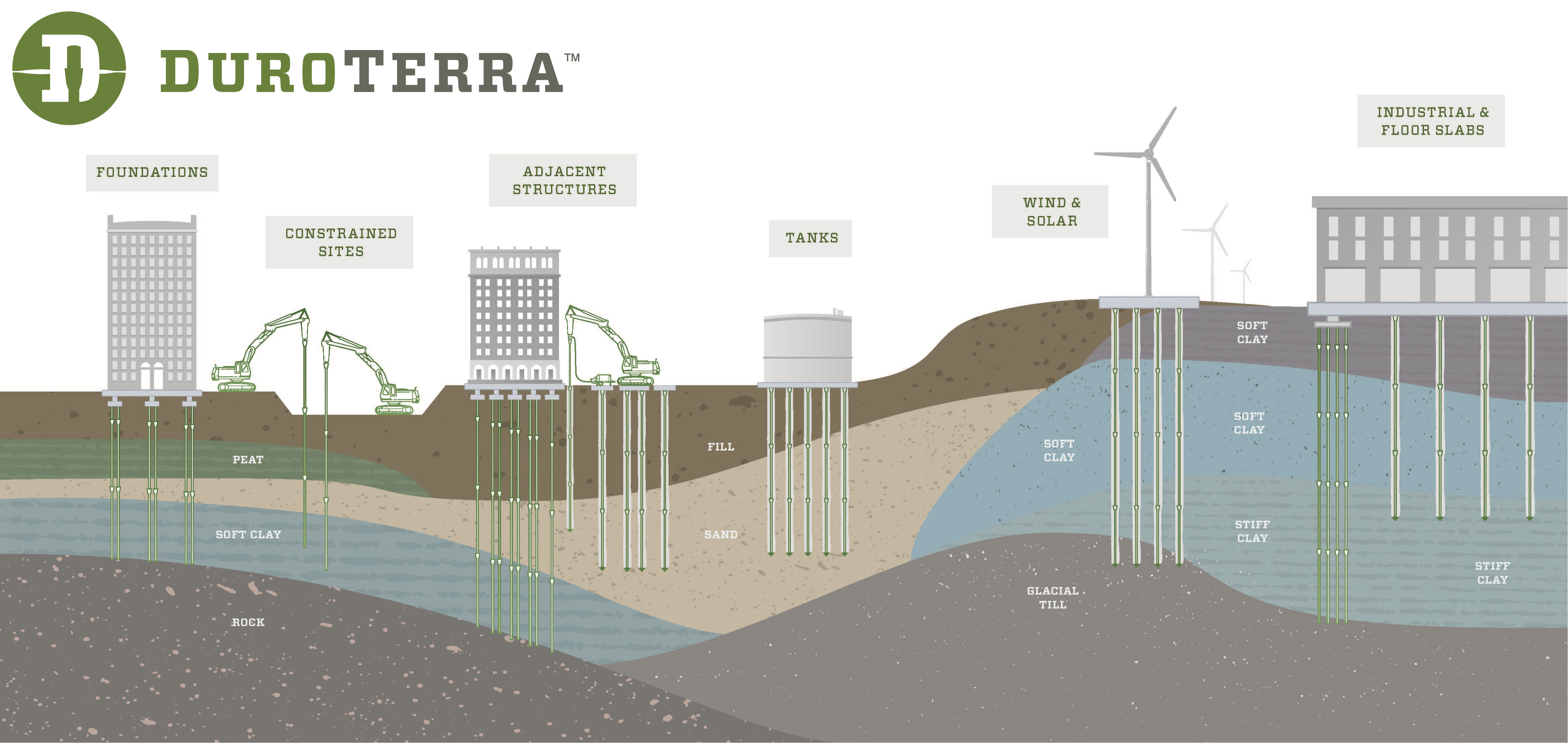

This is a common question that is asked by many geotechnical specialty contractors across the U.S. and Canada. Unlike other foundation systems that require expensive, purpose-built specialty machines, Ductile Iron Piles (DIPs) have been installed for more than 40 years using standard conventional earthwork equipment. In fact, one of the most attractive features of the TRM Ductile Iron Pile system is that it uses conventional earthwork equipment for installation including a medium-duty excavator, hydraulic percussion hammer, and a grout/concrete pump. The amount of specialized equipment and tooling is limited to only the drive tool.

Base tracked excavators used for Ductile Iron Piles are typically in the 20 to 30 ton service or operating weight range. Alternatively, vertical-mast equipment with a hydraulic hammer may also be used for installations. One primary factor for excavator selection is the need to supply the required hydraulic power to the hammer. Compatibility of the excavator with the hydraulic hammer is extremely important to both equipment performance and pile installation. Secondly, selecting an excavator with sufficient reach (height) to easily allow driving on the top of the pile is also important. Experienced installers often customize side-mount hammer brackets to reduce height requirements.

Base tracked excavators used for Ductile Iron Piles are typically in the 20 to 30 ton service or operating weight range. Alternatively, vertical-mast equipment with a hydraulic hammer may also be used for installations. One primary factor for excavator selection is the need to supply the required hydraulic power to the hammer. Compatibility of the excavator with the hydraulic hammer is extremely important to both equipment performance and pile installation. Secondly, selecting an excavator with sufficient reach (height) to easily allow driving on the top of the pile is also important. Experienced installers often customize side-mount hammer brackets to reduce height requirements.

While hydraulic percussion hammers are common and easy to obtain, selecting the proper size is a critical part of the Ductile Iron Pile installation process. Selection of the hammer is critical to ensure 1) adequate hammer energy to drive the piles to depth and/or to obtain proper “set” conditions and 2) excessive hammer energy is avoided for concern of overstressing and damaging the pile during driving. Typical hammer energy ranges from 3,000 ft-lb up to 7,000 ft-lb depending on pile size and driving conditions. Two common hammers used by installers are the Epiroc (Atlas Copco) HB2000 and Tramac v1800. These hammers are well-suited to drive both the Series 118 and Series 170 pile sections. Other, similar sized hammers can also be used and DuroTerra should be consulted to assist with hammer size selection to make sure that the proper hammer and drive shank are used for your application.

Specialty tooling (drive shanks) is required for installation of the Ductile Iron Piles. A dry (solid) solid drive shank is used for dry or non-grouted installations commonly for end-bearing applications. A wet or grout shank is used for exterior grouted installations, typically for friction applications. Drive shanks are the only specialty tool required for Ductile Iron Pile installations. DuroTerra maintains an inventory of dry and wet shanks for some commonly used hydraulic hammers. Driving shank dimensions are specific to hydraulic hammers and custom manufacturing can be provided for nearly any hydraulic hammer.

Specialty tooling (drive shanks) is required for installation of the Ductile Iron Piles. A dry (solid) solid drive shank is used for dry or non-grouted installations commonly for end-bearing applications. A wet or grout shank is used for exterior grouted installations, typically for friction applications. Drive shanks are the only specialty tool required for Ductile Iron Pile installations. DuroTerra maintains an inventory of dry and wet shanks for some commonly used hydraulic hammers. Driving shank dimensions are specific to hydraulic hammers and custom manufacturing can be provided for nearly any hydraulic hammer.

Widely available concrete or grout pumps are required for installation of exterior-grouted Ductile Iron Piles and also during the dry-installation method, to fill the interior of the pile with grout. Like hammer selection, it is important that the grout pump be selected so that it is not too small (insufficient pressure) to introduce grout at depth in the pile, nor is it too large, causing excess pressure resulting in blockages in the line. For mixing neat cement grout, typical high-shear colloidal mixers are used. For delivering sanded grout, often used for exterior grouted piles, swing-tube pumps are most common. Pumps with ¼- to ½-cubic foot/stroke operating in the range of 30 to 50 CY/hour are recommended.

If you are interested in learning more about the equipment requirements, contact us today. Want to see if the Fast, Simple, and Safe™ Ductile Iron Pile system makes sense on your next deep foundation project? Our geotechnical engineers and construction personnel can help you evaluate applicability and feasibility with no up-front obligation. Please contact info@duroterra.com or reach out to your local DuroTerra engineer for more information.

While you’re here, please read this case history that features one geotechnical specialty contractor working on their first Ductile Iron Pile project.

PROJECT EXPERIENCE – DAL-TILE SILO FOUNDATION

Additions to the Dal-Tile manufacturing facility included a new raw-product storage silo. The new silo was planned adjacent to existing silos inside the existing manufacturing plant. With loads of over 800 kips (compression) and 200 kips (uplift), silo support with 60 feet of soft to very stiff clay to rock required a deep foundation system. Ductile Iron Piles were selected over micropiles due to the clean installation process and ability to work in the constrained work area at a reduced cost and time. The Ductile Iron Piles were installed within limited overhead clearance and limited access (narrow aisle widths of 12 ft). Series 118/9.0 piles were installed to terminate on rock to develop 40 tons of capacity in compression and up to 14 tons in tension. Despite being their first project with the system, Chris-Hill Construction completed the work in only two days. Learn more about the project.