Ductile Iron Piles provided a cost-effective solution to support the new foundations with minimal impact on the adjacent structures.

Ductile Iron Piles provided a cost-effective solution to support the new foundations with minimal impact on the adjacent structures.

Project Description:

A new bed tower addition to the Moffitt Cancer Center in Tampa, Florida required a pedestrian bridge to connect the tower to an existing clinic building. The new bridge had to cross a wide, busy arterial street, resulting in a foundation design requiring 13 new foundations. Structural loads on the new foundations were as high as 1,100 kips (compression), 150 kips (tension), and 150 kips (lateral), driven by up to 3,000 ft-kips of overturning moment.

Geotechnical Conditions:

Subsurface conditions encountered at the site consist of 10 to 15 ft thick stratum of loose to medium dense sand underlain by 20 to 30 ft of soft to very stiff plastic clay. Limestone bedrock was encountered below the clay at depths ranging from 35 to 45 feet.

Project Challenges:

- Provide a cost-effective solution to support the new foundations with minimal impact on the adjacent structures.

- Provide a low vibration solution that could be installed quickly and safely in constrained working areas that would not disrupt traffic or hospital activities.

- Provide a driven pile solution that could easily accomodate variable bedrock elevations.

Advantages

- Simple, low-vibration installation near existing structures

- Small diameter, high capacity load resistance

- Rapid turn-key operation

- Superior load test performance

Design and Construction Solution

The design team considered driven pipe piles, drilled micropiles, and Ductile Iron Piles (DIPs) for support of the new foundations. Early project budgeting revealed that the DIP solution would provide the best combination of performance, ease of construction, and low cost. Earth Tech Geotechnical Construction Services was selected to install the Ductile Iron Pile system.

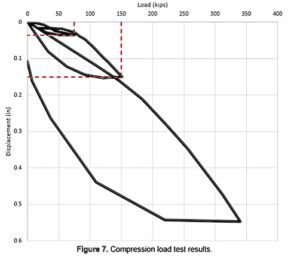

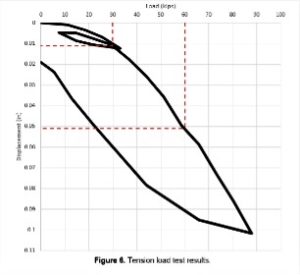

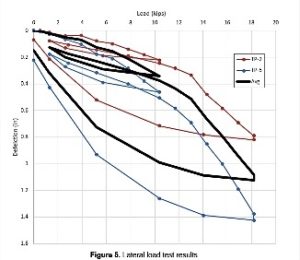

The Ductile Iron Pile design featured Series 118/7.5 piles (118 mm diameter with wall thicknesses of 7.5 mm) with an oversized 220 mm conical drive shoe. The oversized drive shoe creates an annular space during driving of the pile. Sand cement grout is continuously pumped through the wet drive shank, down through the pile and out through grout ports in the drive shoe to completely encapsulate the pile with grout during driving. The end result is a fully grouted pile that develops substantial grout-to-ground bonding for frictional capacity. Earth Tech engineers designed the exterior-grouted piles for allowable compression capacities of 75 kips, tension capacities of 30 kips, and lateral capacities of up to 7.7 kips.

Earth Tech installed a total of 183 Ductile Iron Piles to depths ranging from 34 to 107 feet with minimal pile waste due to the innovative Plug and Drive connection. Pile load testing was performed to validate the design axial, tension, and lateral capacities. The test results confirmed acceptable performance results.

Project Team Members

DIP Installation Partner: Earth Tech

Geotechnical Engineer: Terracon, Inc.

Structural Engineer: Walter P. Moore & Associates

General Contractor: Barr & Barr