Ductile Iron Piles provide a low vibration, cost-effective foundation support solution on the constrained, urban site

Project Description:

The project consisted of a new 4-story building addition with a footprint of only 4,800 square feet. The addition was positioned between two existing buildings in downtown Cedar Rapids. Column loads were up to 700 kips.

Geotechnical Conditions:

Soil conditions consisted of 9 to 18 feet of variable fill underlain by sand to depths of up to 20 feet followed by stiff to very stiff glacial clay. Limestone bedrock was encountered at depths of 66 to 85 feet below grade. Groundwater was encountered at 10 to 12 feet.

Project Challenges:

Provide a low vibration, cost-effective foundation support solution on the constrained, urban site.

Advantages

- High Capacity

- Low vibrations during installation

- Smaller equipment for constrained sites

- Modular pile sections to reach deep rock yet limit laydown area

Design and Construction Solution

Navigating deep foundation installations on the urban, limited-access site with deep bedrock was the main challenge for the project team. Designers originally considered augercast piles and drilled shafts for support of the building addition. A Ductile Iron Pile value engineered alternative was proposed to the project team and ultimately selected based on the cost, low vibrations and ease of installation on the tight site.

Project foundation designs were prepared based on a 50 ton working capacity Ductile Iron Pile system. Designers of the piles selected a Series 118/9.0 (118 mm outer diameter with 9 mm wall thickness) Ductile Iron Pile manufactured by Austrian-based TRM to provide adequate structural capacity.

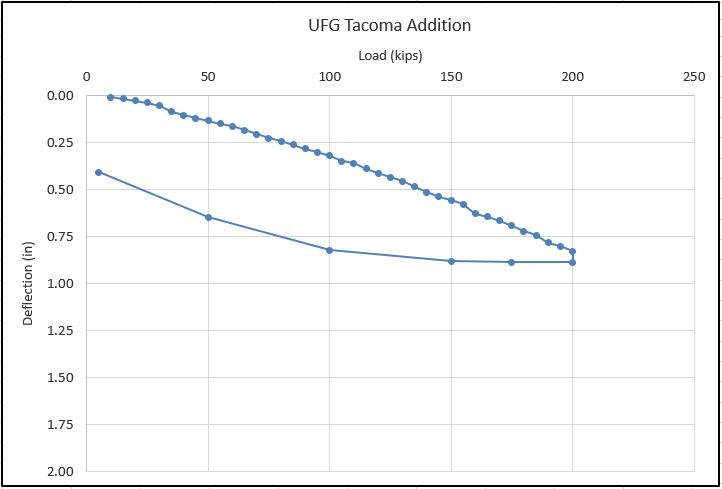

The piles were designed to penetrate the fill, sand and glacial clay to terminate on limestone. A total of 63 piles were required to support building loads. Pre-production load testing was performed by pile installer, Peterson Contractors, Inc. on a pile terminating on rock at a depth of 72 feet. Pile deflections of 0.32 inches and 0.89 inches were recorded at loads of 50 tons (100% design load) and 100 tons (200% design load), respectively. Following excavation of the pile caps, the production piles were installed to rock and terminated upon reaching the set observed in the load test.

Project Team Members

DIP Designer: Ground Improvement Engineering, Inc.

DIP Installer: Peterson Contractors, Inc.

Geotechnical Engineer: Terracon Consultants, Inc.

Structural Engineer: Schnoor-Bonifazi Engineering & Surveying, L.C.