DuroTerra Dialogue: In a Tight Spot? The Right Solution for Low Overhead Clearance

In a Tight Spot? The Right Solution for Low Overhead Clearance

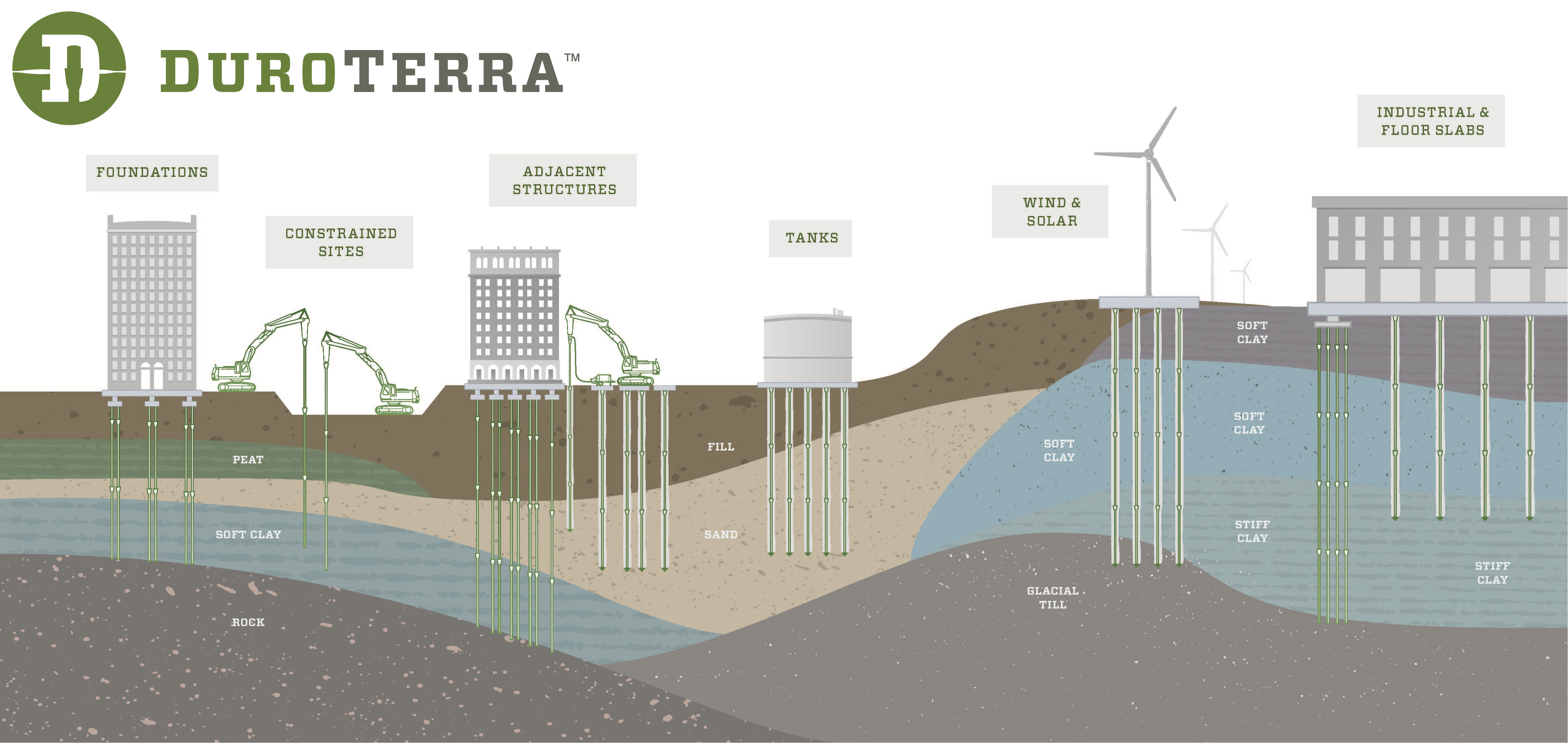

What is your deep foundation of choice when facing overhead clearance restrictions on your project? Many engineers and contractors turn to helical piles or micropiles when working inside existing buildings or with limited overhead clearance. Did you know that Ductile Iron Piles (DIPs) can work in areas with as little as 18 feet of clearance – usually with higher capacities than helical piles while faster, cleaner and less expensive than micropiles?

Don’t be misled by the driven installation method used for the Ductile Iron Pile system. DIPs are installed with medium-sized excavators and percussion hammers that can fit in tight spots. Overhead access of 25 to 30 feet is ideal to drive each 5 meter (16.4 ft) modular section of Ductile Iron Pile in a normal manner. Yet, many of our projects are installed in as little as 18 or 20 feet of overhead by simply cutting the piles in half and using drive-on couplers to rapidly complete the installation. And with the high frequency percussion hammers, vibrations from the driving are safe and well below typical tolerances.

Why consider a Ductile Iron Pile option for limited overhead conditions?

- Reduced cost compared to micropiles and other low headroom option

- Improved speed of installation to complete your project faster

- Cleaner, simpler installation

- Safe operation

Check out a couple of recent limited clearance projects below or visit our website for many more. Have a challenging project? See how Ductile Iron Piles are a fast, simple and safe option for you.

Relevant projects

Construction of a new mezzanine level at an international shipping facility air hub near the Philadelphia International Airport required deep foundations to support loads up to 516 kips at 74 new column locations. Piles were needed to penetrate the soft silt and clay and loose sand extending to depths of at least 65 feet. Overhead clearances were limited to 35 feet in many locations but approached only 20 feet in some areas. Learn more about this award-winning project and how Ductile Iron Piles were installed to depths ranging from 67 feet to more than 100 feet to deliver capacities ranging from 45 to 75 tons.

The addition of a new crane system within the existing Norfolk Southern Mill required 25-ton piles to support the new foundations. With 20 feet of overhead clearance combined with challenging fill conditions, the project was originally specified for drilled micropiles. A value engineered alternative consisting of Ductile Iron Piles replacing the micropiles on a 1:1 basis was selected based on speed and cost. The grouted displacement piles were installed to penetrate the fill and soft to stiff silt and clay to develop grout-to-ground bonding capacity in medium dense sand below. A total of 48 piles were installed in only 3 days.