Got Tension? It’s No Problem for Ductile Iron Piles

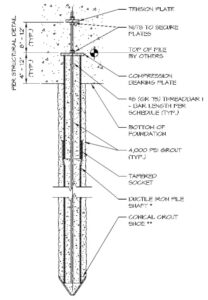

Seismic overturning, wind pressures, retaining wall uplift loads or even structural configurations often result in tension demands on foundations. You might be surprised to know that Ductile Iron Piles can offer a deep foundation solution to resist high tension loads, in addition to compression loading. While the unique Plug-and-Drive (bell-spigot) connection forms a friction welded joint that resists considerable tension, the recommended approach for tension resistance utilizes a high-strength threaded center bar designed for the full tension demand. The center bar is wet-set in the cement grout on the interior of the pile. The structural tensile capacity of the pile is determined solely on the strength of the centerbar. With the pile embedded in the cement grout, the geotechnical tensile capacity is generated through friction along the perimeter area of the pile through either interface friction between the soil and the roughened pile surface for a non-grouted (exterior) pile or through grout-to-ground frictional capacity for an exterior grouted pile.

Seismic overturning, wind pressures, retaining wall uplift loads or even structural configurations often result in tension demands on foundations. You might be surprised to know that Ductile Iron Piles can offer a deep foundation solution to resist high tension loads, in addition to compression loading. While the unique Plug-and-Drive (bell-spigot) connection forms a friction welded joint that resists considerable tension, the recommended approach for tension resistance utilizes a high-strength threaded center bar designed for the full tension demand. The center bar is wet-set in the cement grout on the interior of the pile. The structural tensile capacity of the pile is determined solely on the strength of the centerbar. With the pile embedded in the cement grout, the geotechnical tensile capacity is generated through friction along the perimeter area of the pile through either interface friction between the soil and the roughened pile surface for a non-grouted (exterior) pile or through grout-to-ground frictional capacity for an exterior grouted pile.

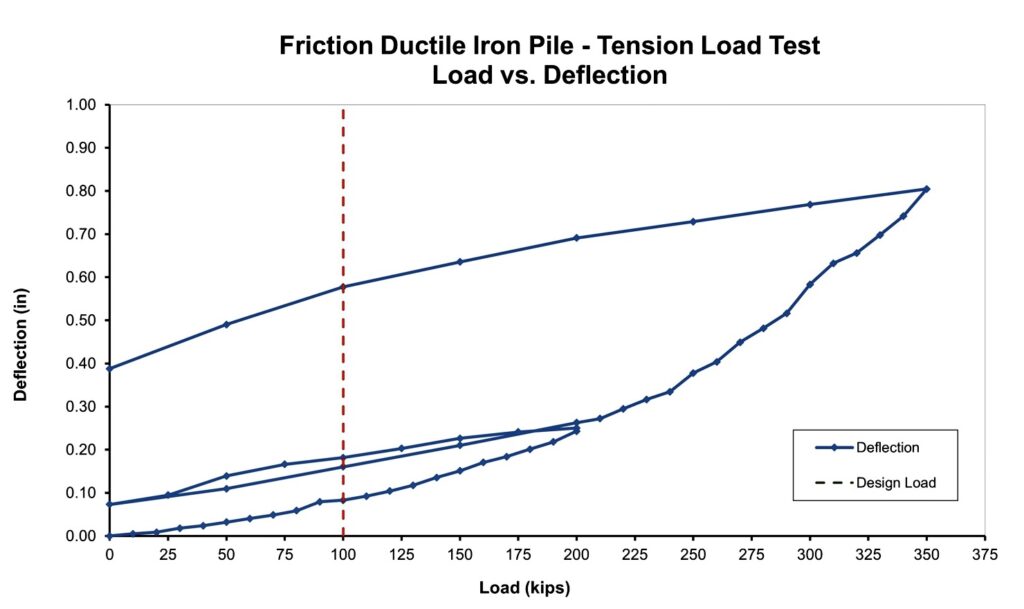

How much tension capacity can you actually achieve? That depends on several factors, including; soil conditions, pile length, pile diameter, center bar capacity, and whether the pile is installed with exterior grout or not. It’s as simple as evaluating the structural capacity of the center bar in tension and the geotechnical frictional capacity along the exterior of the pile. So…how much capacity? In a recent tension test program, an exterior grouted Ductile Iron Pile installed with a 10.6-inch (270 mm) diameter grout shoe achieved 350 kips in only a 32-ft long pile. The test was stopped at 350 kips to avoid overstressing the center bar even though greater geotechnical capacity was available.

Many of the same benefits offered by the Ductile Iron Pile system for working on constrained sites also apply to tension resistance:

- Rapid Installation

- Reduced cost compared with traditional micropiles

- Limited laydown requirements

- Mobile equipment for ease of working on tight sites or variable grades

Looking at a project with tension requirements or simply looking to learn more about tension or other DIP technical details or installation, please reach out. Want to learn more about tension applications – read on and see how we DIPs have resisted tension on other projects. FAST. SIMPLE. SAFE.™

PROJECT EXPERIENCE – MOFFITT CANCER CENTER PEDESTRIAN BRIDGE

A new tower addition to the Moffitt Cancer Center required a pedestrian bridge to span a busy arterial street and connect the tower to the existing clinic building. The bridge required support of 13 new foundations with loads of 1,100 kips (compression), 150 kips (tension) and 150 kips (lateral). Subsurface conditions consisted of 10 to 15 feet of loose to medium dense sand underlain by 20 to 30 feet of soft to very stiff clay followed by limestone bedrock at depths of 35 to 45 feet. Ductile Iron Piles were selected on the project to provide a cost-effective, low vibration solution that could easily work around the constrained area and also address the potential for variable bedrock depths. A solution consisting of exterior grouted Series 118/7.5 Ductile Iron Piles with a 220 mm grout shoe was designed to provide an 8.5-inch grouted displacement pile to resist the design loads. Tension loads of up to 30 kips were incorporated into the design. EarthTech, a MENARD company, installed a total of 183 Ductile Iron Piles to depths ranging from 34 feet to 107 feet.

PROJECT EXPERIENCE – BEEKMAN AVENUE BRIDGE REPLACEMENT

Ductile Iron Piles were used as an alternative to drilled micropiles to support the new bridge abutments for a single span bridge over the Metro North Railroad. Helical Drilling installed DIPs to replace the micropiles on a 1:1 basis – delivering 100 ton working capacity in compression and 30 ton working capacity in tension. Pile performance was verified with full-scale load testing to 250 tons in compression and 7 tons in tension. The Ductile Iron Pile solution provided a low vibration solution to address the loading demands with a cleaner, faster and less expensive piling option.